Telescopic feed beam for rock drill and method of measuring rock drill travel

A drilling machine, telescopic technology, applied in drilling equipment and methods, drilling measurement, drill pipe, etc., can solve problems such as unreliable operation, complex detection and measurement processing skills, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

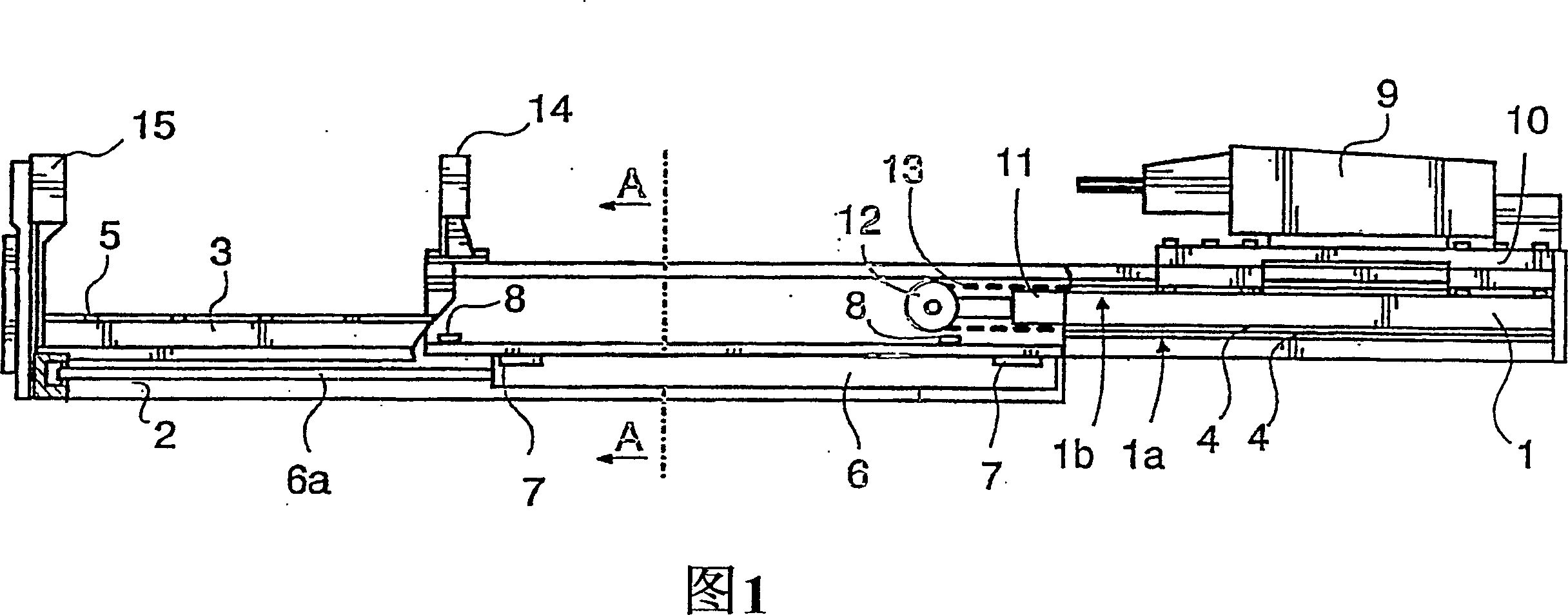

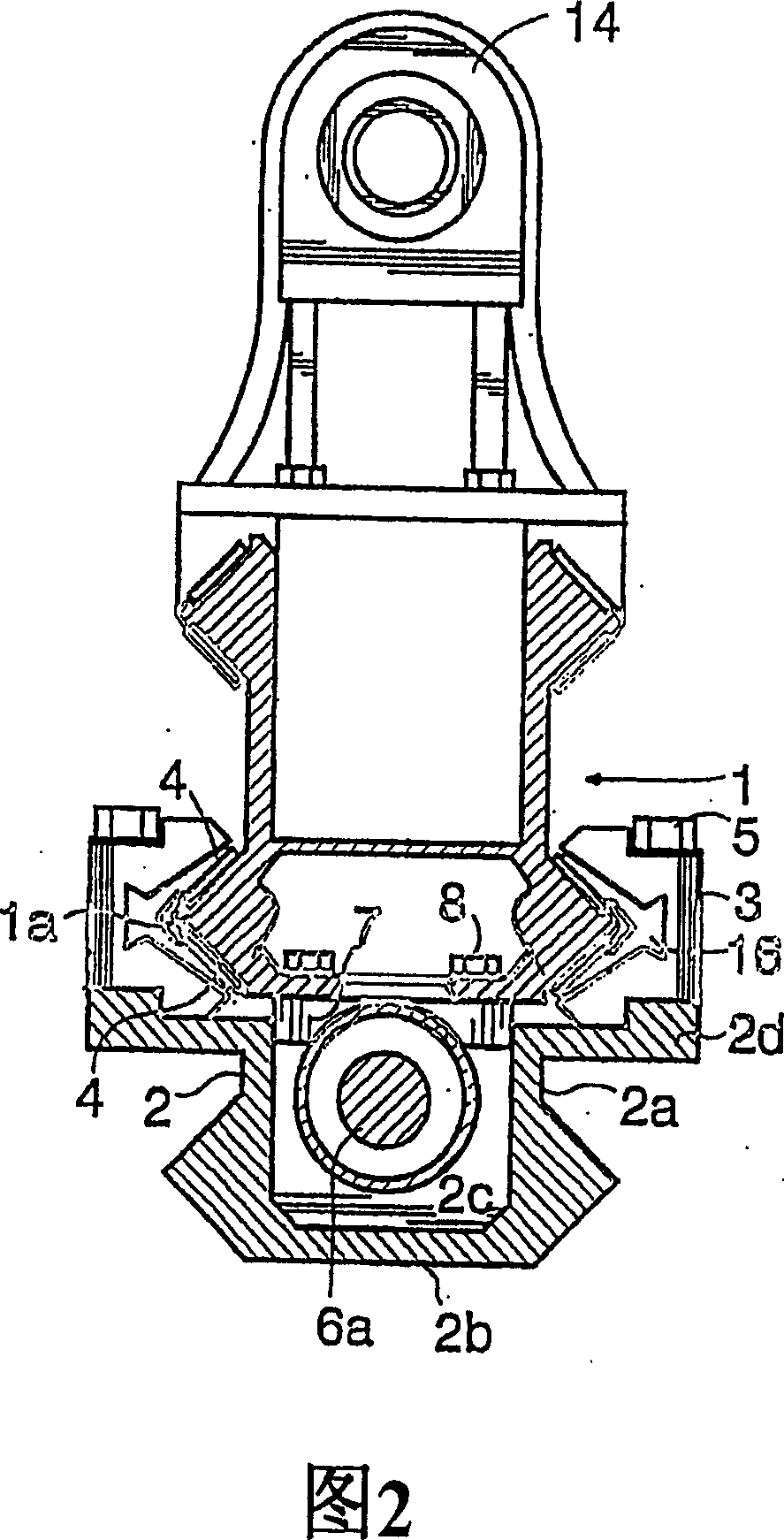

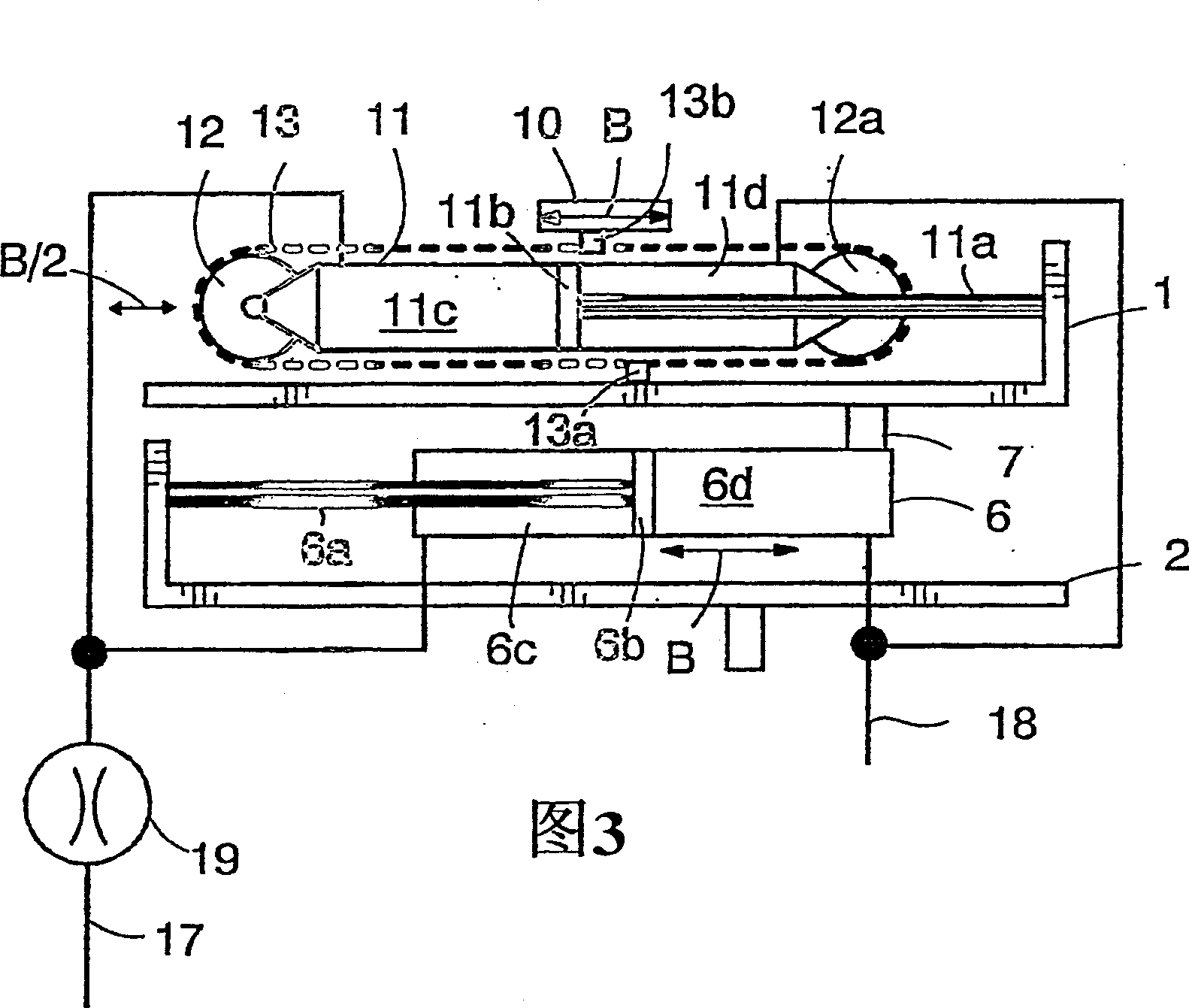

[0014] FIG. 1 shows a telescopic feed rod comprising an upper rod 1 and a lower rod 2 . The upper bar 1 and the lower bar 2 are mutually slidably installed along the longitudinal direction thereof by means of a slide rail 1a under the upper bar 1 and a slider 3 connected to the lower bar 2 . The upper rod 1 is manufactured from, for example, an aluminum alloy by extrusion, and its sliding surface is preferably formed at the same time. The sliding track has a sliding surface 4 for the slider, which is usually a steel band in an aluminum rod or the like. While the slide 3 is again most preferably made of aluminum profiles, slides are connected to the slide 3 in the manner shown in FIG. 2 , the slides being in contact with the sliding surface 4 . The slider 3 is connected to the lower rod 2 with a bolt 5 . At the front end of the lower bar 2, preferably the slider extends substantially over the entire length of the upper bar 1, the sliding means thus supporting the upper bar ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com