Linkwork of quick press roller handle and plug

A linkage device and speed printing machine technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of complex front plate structure, high failure rate, cumbersome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

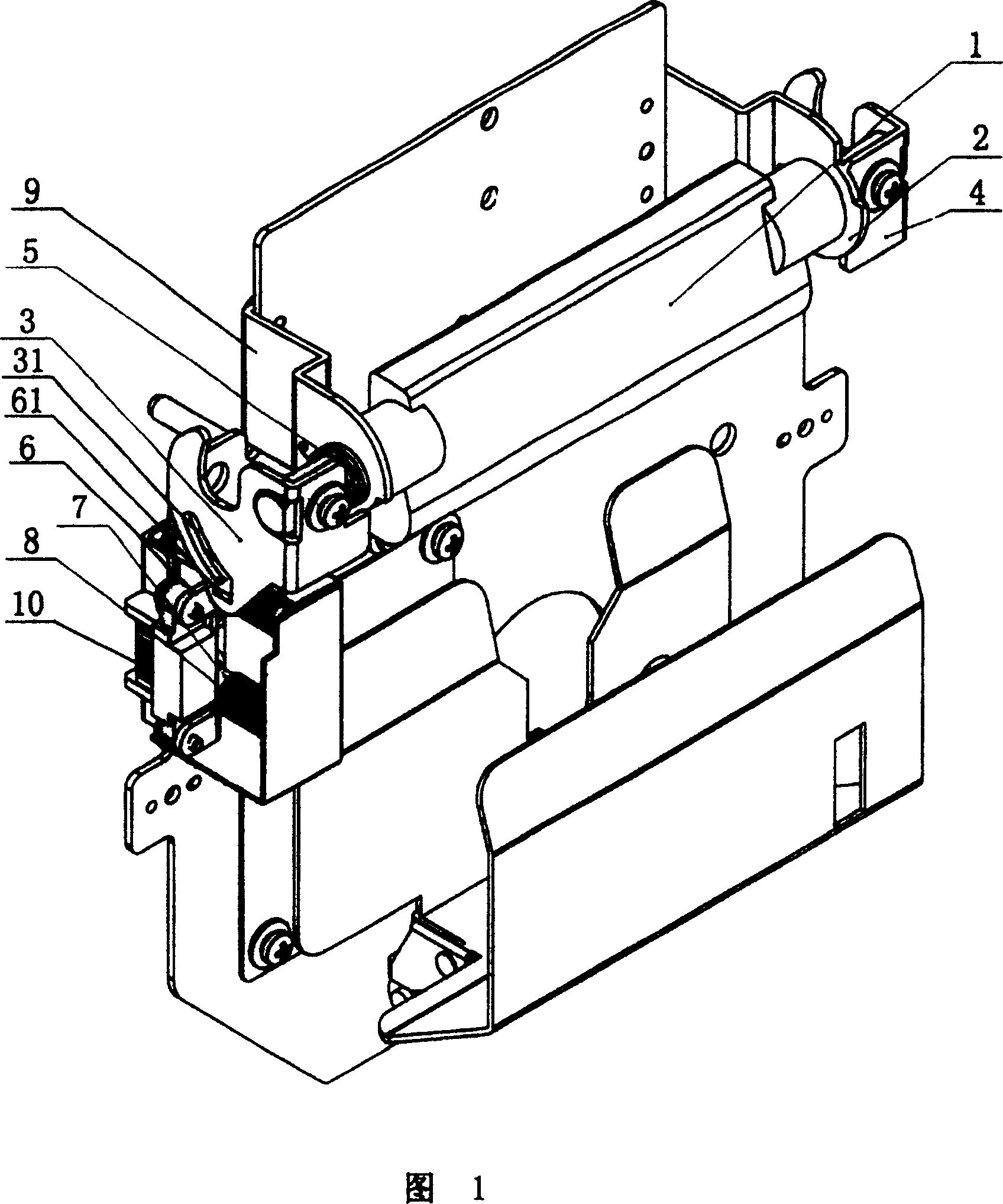

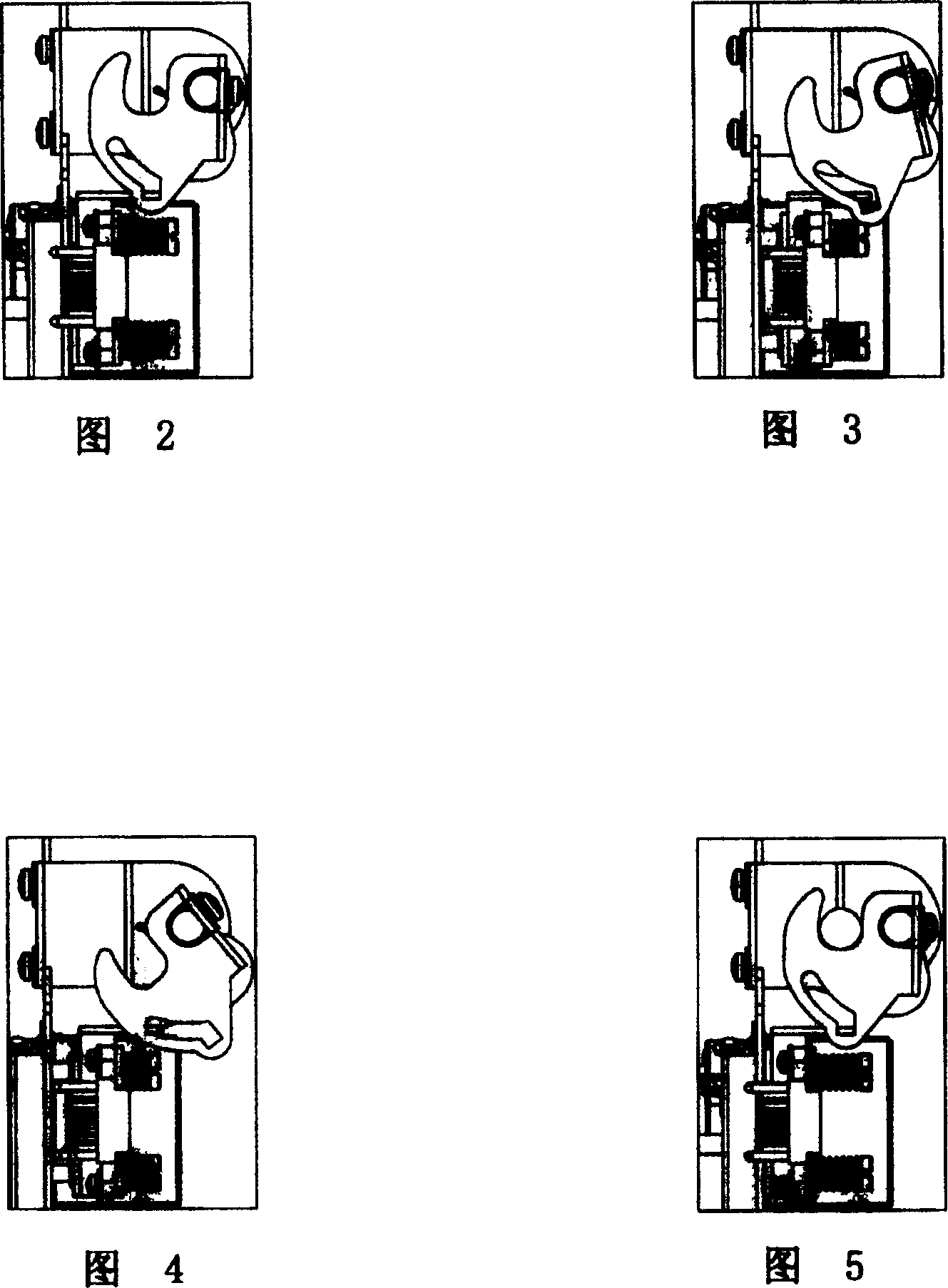

[0009] As shown in Figure 1, the cylinder handle and plug linkage device of the instant printing machine includes a rotatable handle body 1 installed on the corner piece 2 of the front end plate 9 of the instant printing machine cylinder, and the handle body 1 The left hook 3 and the right hook 4 of the locking cylinder are fixed on the top, and a torsion spring 5 that can reset the handle body 1 is provided between the handle body 1 and the front end plate 9 of the cylinder; The plug bracket 6 for installing the plug 10 on the side of the front plate 9, the guide shaft 7 that guides the plug bracket 6 and the compression spring 8 that prevents the plug from coming out automatically due to vibration; the plug bracket 6 is provided with a push plug 10 to insert or pull out Out of the toggle arm 61, the left hook 3 or the right hook 4 corresponding to the plug bracket 6 is provided with a toggle arm groove, and the end of the toggle arm 61 is inserted into the toggle arm groove. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com