Process for preparing nano barium titanate and doped solid solution by low temperature solid state reaction

A solid-state reaction, barium titanate technology, applied in self-solid, chemical instruments and methods, crystal growth, etc., can solve the problem of uneven chemical composition distribution of barium titanate powder, easy agglomeration of barium titanate powder, and uneven particle size distribution Uniformity and other issues, to achieve high theoretical and practical value, avoid hard agglomeration, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Preparation of pure nano barium titanate solid solution

[0033] 1. Formation of metatitanic acid

[0034] 11ml (0.1mol) of TiCl 4 Drop into 100-200ml of deionized water, then adjust the pH to 6-8 with ammonia water, make a slurry, filter under reduced pressure, wash the chloride ions, and then drain to obtain a filter cake that is metatitanic acid (H 2 TiO 3 or TiO 2 ·H 2 O).

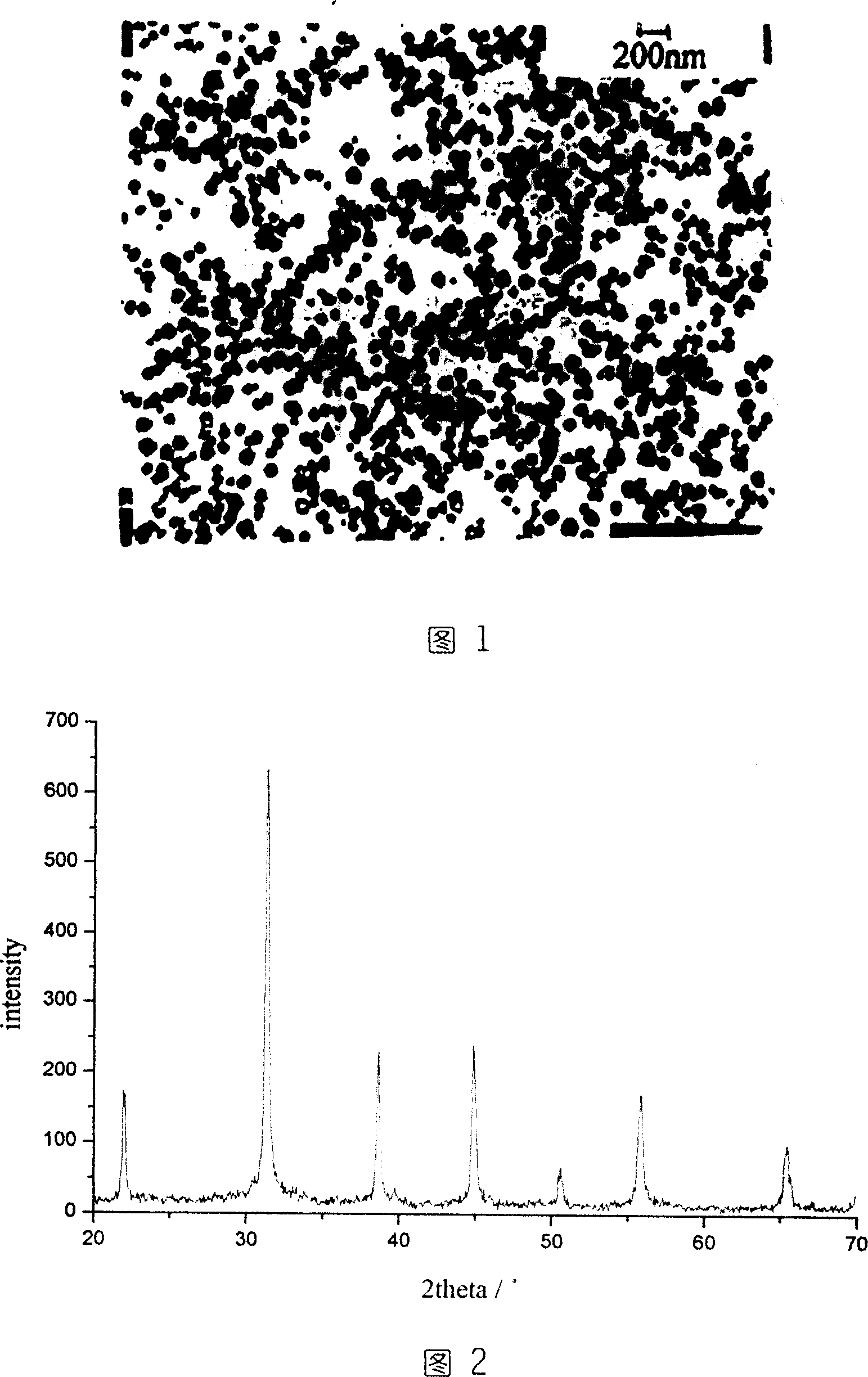

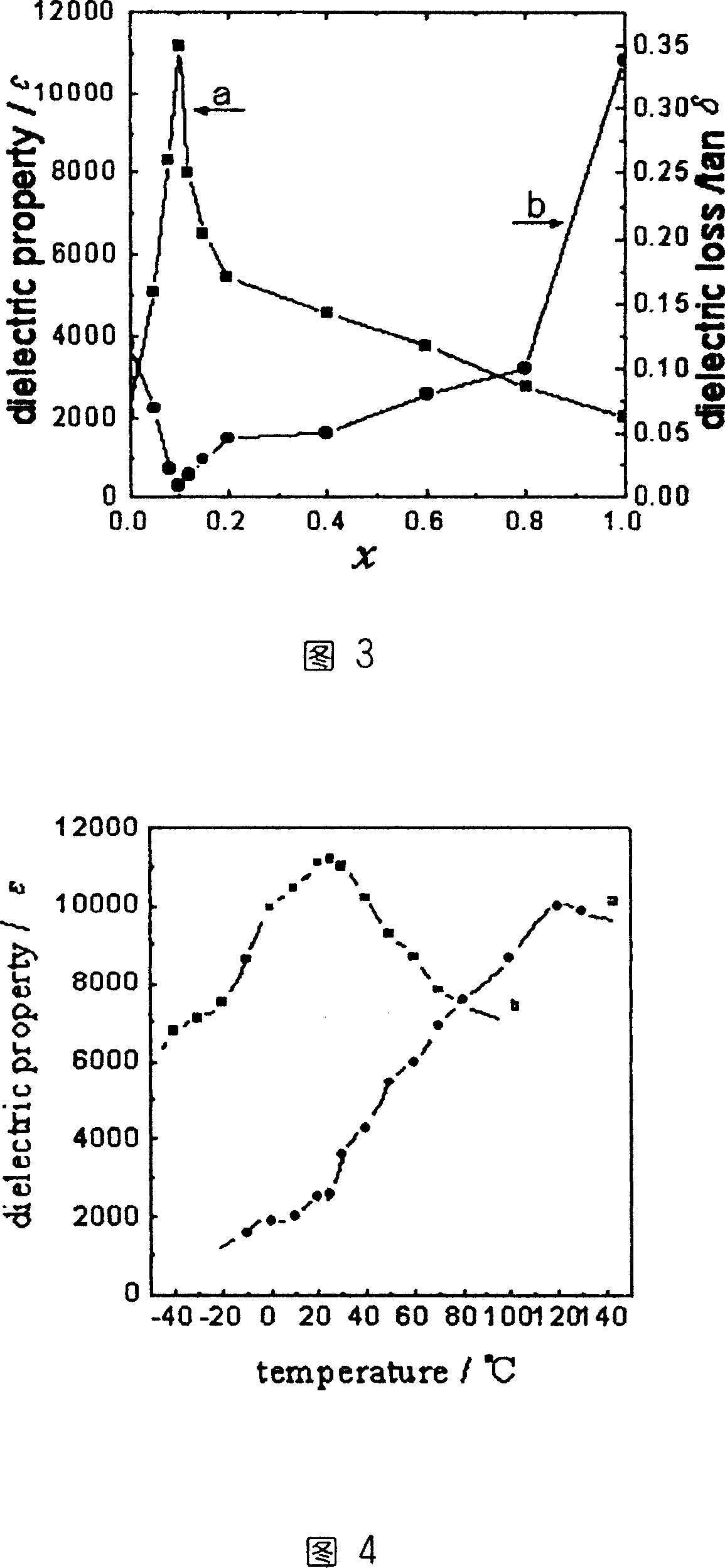

[0035] 2. Grinding and drying

[0036] Filter cake according to effective content and solid Ba(OH) 2 ·8H 2 O is mixed at a molar ratio of 1:1, fully ground at room temperature for 30-60 minutes, and then directly dried at 100°C to obtain BaTiO with an average particle size of 50-70nm and a cubic phase. 3 Powder, as shown in Figure 1 and Figure 2. The room temperature dielectric constant of the barium titanate ceramics prepared by the invention can reach more than 4000. However, barium titanate obtained by high-temperature sintering in the prior art has a dielectric constant...

Embodiment 2

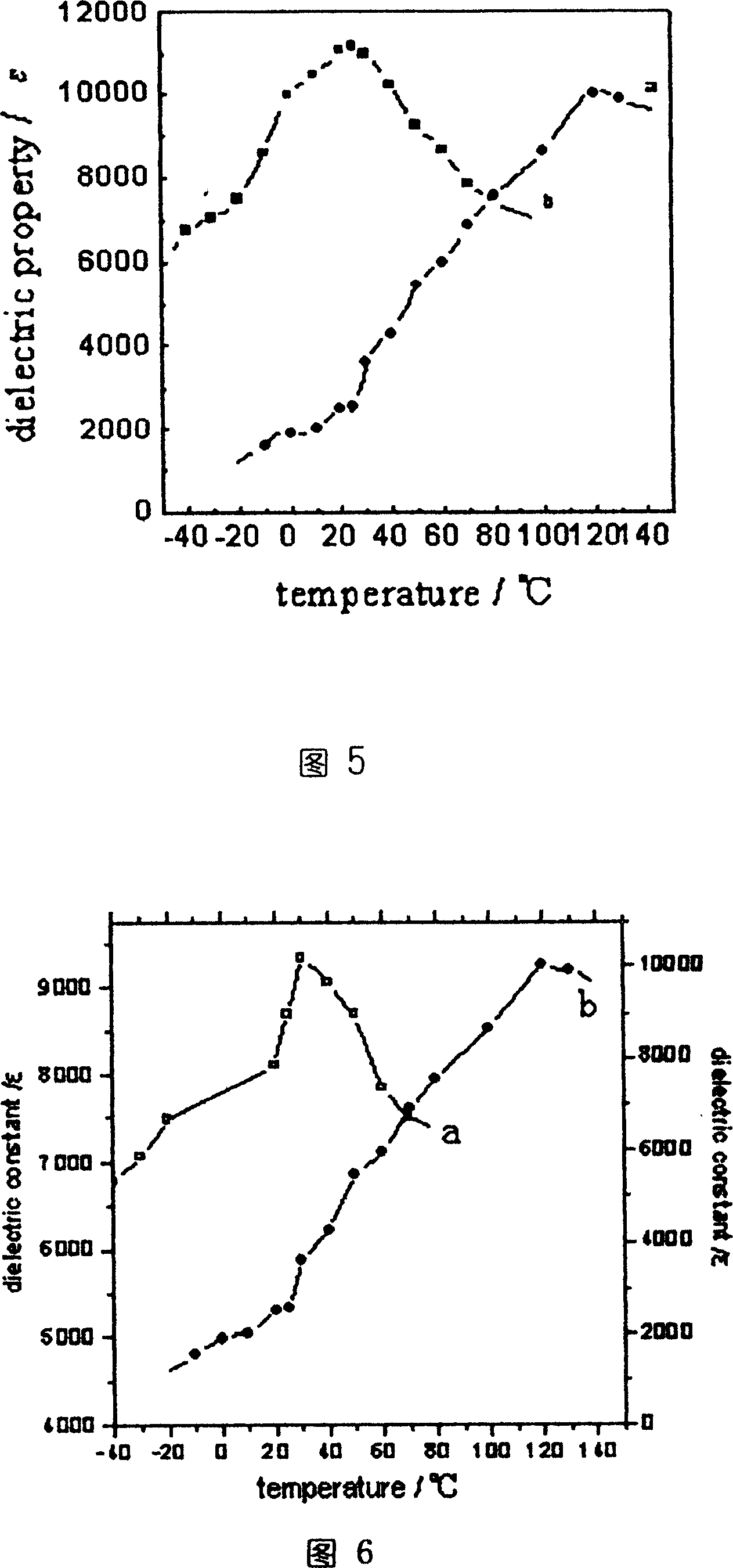

[0037] Embodiment 2: to BaTiO 3 (ABO 3 ) solid solution for A-site doping to synthesize Ba 1-x m x TiO 3

[0038] Doped with strontium (Ba 0.9 Sr 0.1 TiO 3 ) as an example: TiCl 4 Hydrolysis process is the same as embodiment 1, and the filter cake that washes off chloride ion is according to effective content and fresh solid Ba(OH) 2 ·8H 2 O and Sr(OH) 2 ·8H 2 O was mixed at a molar ratio of 1:0.9:0.1, fully ground at room temperature for 30-60 minutes, then moved into a crucible, and dried at 120°C to obtain cubic phase Ba with an average particle size of 30-50 nm. 0.9 Sr 0.1 TiO 3 Powder. in Ba 1-x m x TiO 3 In the system, the value of X is between 0, 0.03, 0.05, 0.08, ... until 1.0, and X can take a value continuously or intermittently.

[0039] The pottery test proves that after the method of the present invention is used to dope an appropriate amount of strontium in the barium titanate, the dielectric constant of the material at room temperature can reac...

Embodiment 3

[0040] Example 3. To BaTiO 3 Synthesis of BaTi with B-site Doping in Solid Solution 0.9 N 0.1 o 3

[0041] Doped with tin (BaTi 0.9 sn 0.1 o 3 ) as an example: 9.9mlTiCl 4 , 3.5058g SnCl 4 ·5H 2 After the joint hydrolysis of O, ammonia water was added to make a slurry, the pH was adjusted to 6-8, and the chlorine ions were washed by vacuum filtration, and then the filter cake was mixed with fresh solid Ba(OH) according to the effective content. 2 ·8H 2 O was mixed at a molar ratio of 1:1, fully ground at room temperature for 30-60 minutes, and then placed in an oven at 120°C for direct drying. Nano-BaTi can be prepared 0.9 sn 0.1 o 3 Solid solution powder. BaTi 1-x N x o 3 The value of x in it is: 0.01, 0.02, 0.03, ..., 0.1, 0.15, 0.2, 0.25, 0.3. X can take values continuously or intermittently.

[0042] The pottery test proves that after the method of the present invention is used to add a proper amount of tin to the barium titanate, the dielectric consta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap