A kind of preparation method and application of nano-silicon material

A technology of nano-silicon and nano-silicon powder, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of increasing equipment cost and environmental pollution, unfavorable to industrial production, reducing material performance, etc. problems, to avoid hard agglomeration, facilitate grinding, and reduce grinding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of nano-silicon material of the present invention, comprises the following steps:

[0037] (1) Weigh 1 kg of industrial silica fume, place it in a jaw crusher for crushing for 2 hours, and place it in a ball mill for crushing for 3 hours to obtain coarse silica fume with a particle size of 50-500um;

[0038] Add 4kg of absolute ethanol to the obtained coarse silicon powder, pass through a 32-mesh sieve after high-speed stirring at 500rpm, and obtain a coarse silicon powder slurry;

[0039] (2) Add boron nitride balls (the median diameter of the boron nitride balls are 0.3mm, 3mm, 50mm, and the mass ratio is 3:2:1) to the coarse silicon powder slurry prepared in step (1), Proportion according to the material mass ratio of 1:1;

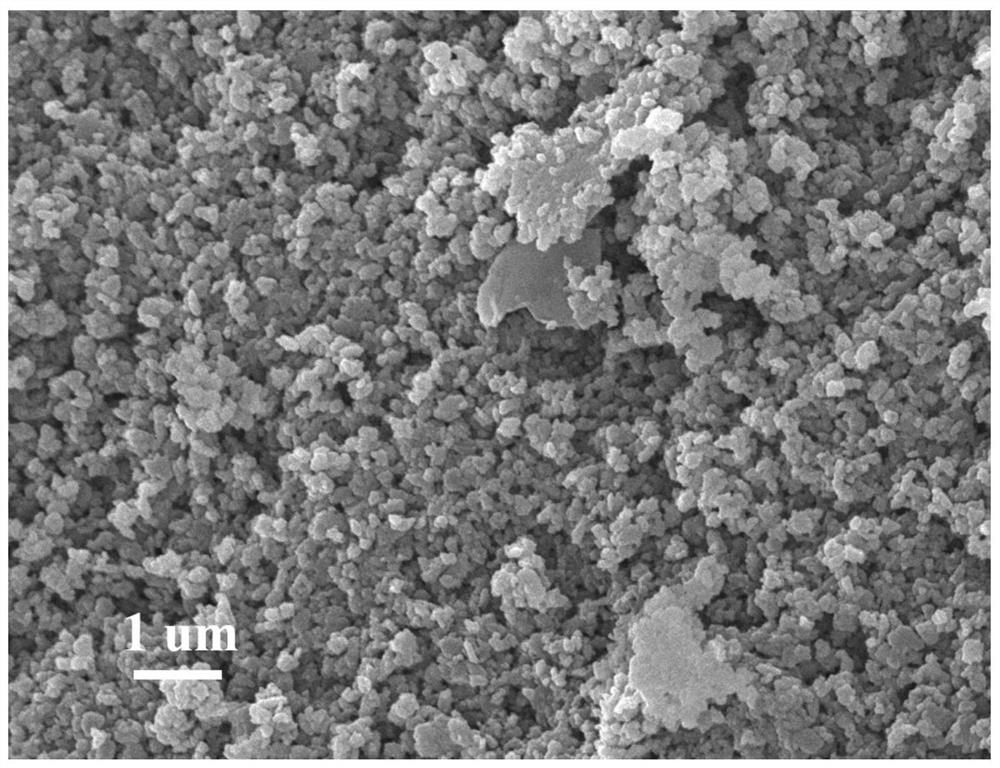

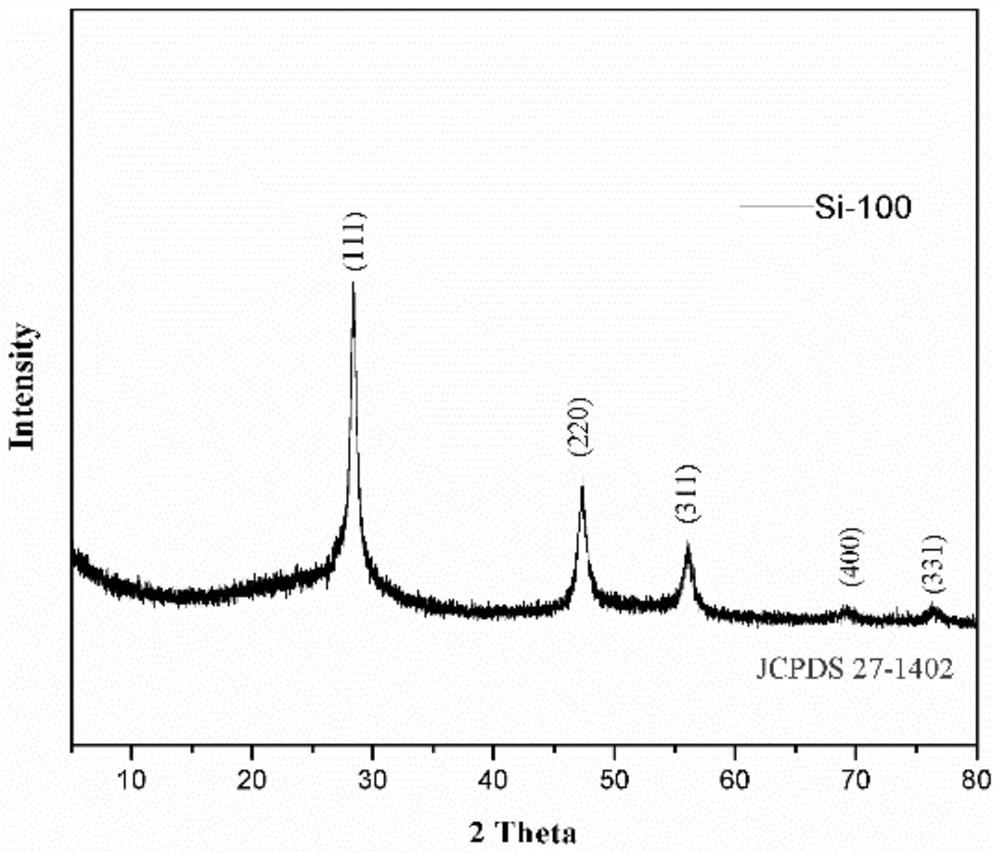

[0040]Put the slurry in a high-energy planetary ball mill with a closed protective gas (high-purity nitrogen) and grind it for 15 hours (rotational speed 800rpm), and pass through a 325-mesh sieve to obtain a uniformly dispe...

Embodiment 2

[0045] A preparation method of nano-silicon material of the present invention, comprises the following steps:

[0046] (1) Weigh 500g of polysilicon block, place it in a jaw crusher for crushing for 2 hours, and crush it in a ball mill for 2 hours to obtain coarse silicon powder with a particle size of 50-500um;

[0047] Add 9kg of isopropanol to the obtained coarse silicon powder, and pass through a 32-mesh sieve after high-speed stirring (500rpm), to obtain a coarse silicon powder slurry;

[0048] (2) Add zirconia balls (the median diameter of zirconia balls are 0.5mm, 5mm, 80mm, and the mass ratio is 3:2:1) to the coarse silica powder slurry prepared in step (1), according to the material The mass ratio is 1:1 for proportioning;

[0049] Put the slurry in a high-energy planetary ball mill with a closed protective gas (high-purity argon) and grind it (rotation speed: 800rpm) for 10 hours, and pass through a 325-mesh sieve to obtain a uniformly dispersed micron-sized silicon...

Embodiment 3

[0059] A preparation method of nano-silicon material of the present invention, comprises the following steps:

[0060] (1) Weigh 500g of silicon microcrystals, place them in a jaw crusher for crushing for 2 hours, and place them in a ball mill for crushing for 3 hours to obtain coarse silicon powder, the particle size of which is concentrated at 50-500um;

[0061] Add 5kg of polyvinylpyrrolidone to the prepared coarse silicon powder, and pass through a 32-mesh sieve after high-speed stirring (200rpm) to obtain a coarse silicon powder slurry;

[0062] (2) Add tungsten carbide spheres (the median diameter of tungsten carbide spheres are 1.0mm, 10mm, 50mm, wherein the mass ratio is 3:2:1) to the coarse silicon powder slurry prepared in step (1), according to The material mass ratio is 1:1 for proportioning;

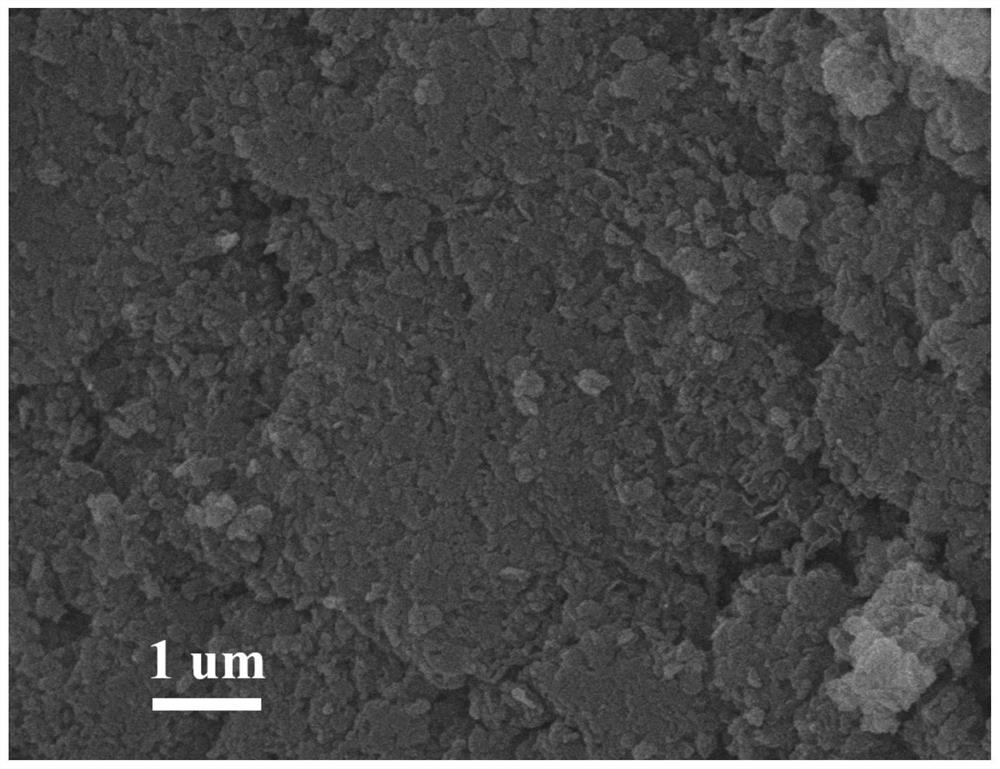

[0063] Put the slurry in a cone mill with a closed protective gas (argon) and grind it at a speed of 2000rpm for 10h, pass through a 325-mesh sieve to obtain a uniformly di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com