Double pump confluence type multi-way ratio control valve with load sensitivity information circuit

A double-pump confluence and control valve technology, which is applied to fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve problems such as low volumetric efficiency, technical level gap, and influence on the handling performance of hydraulic truck cranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

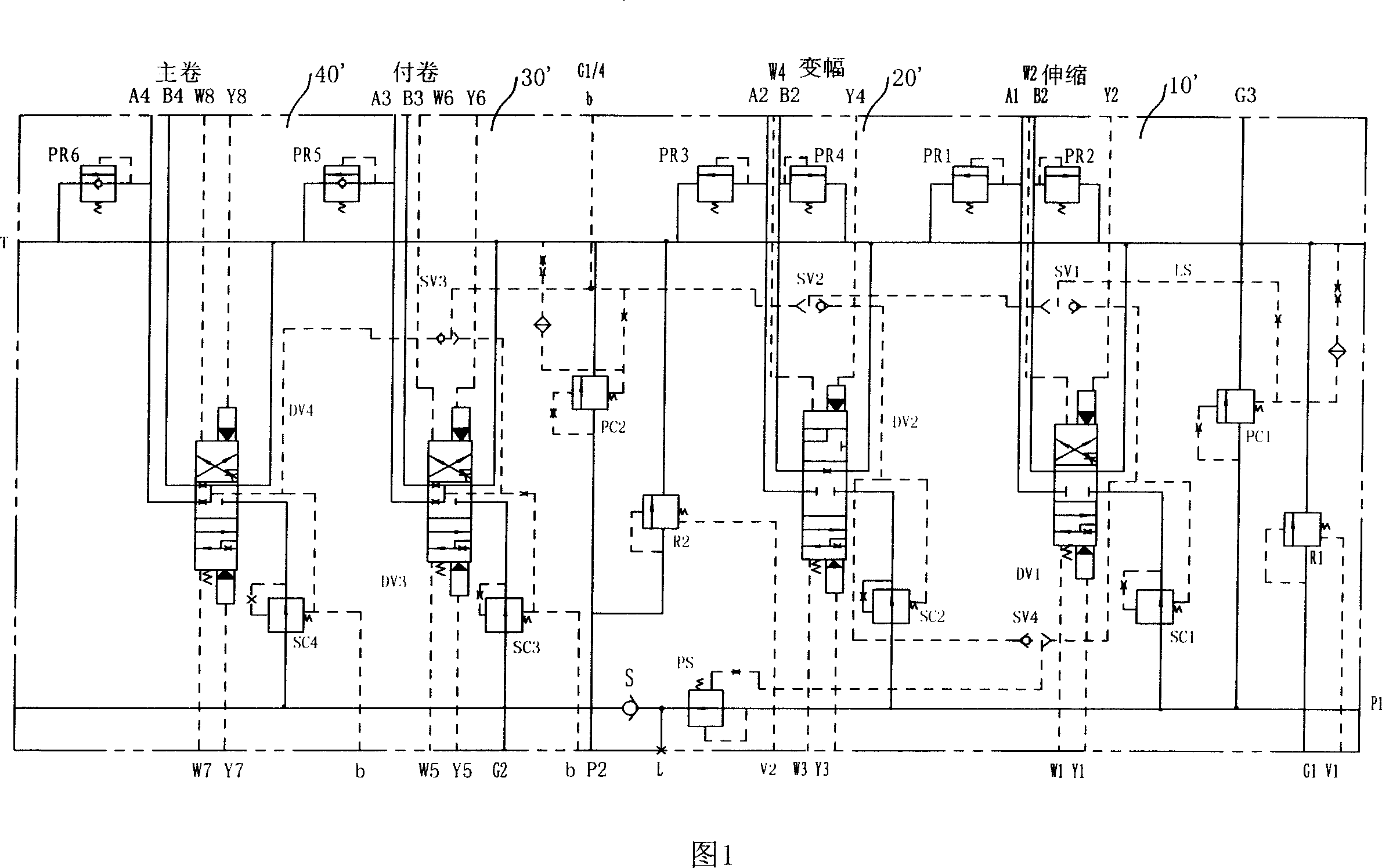

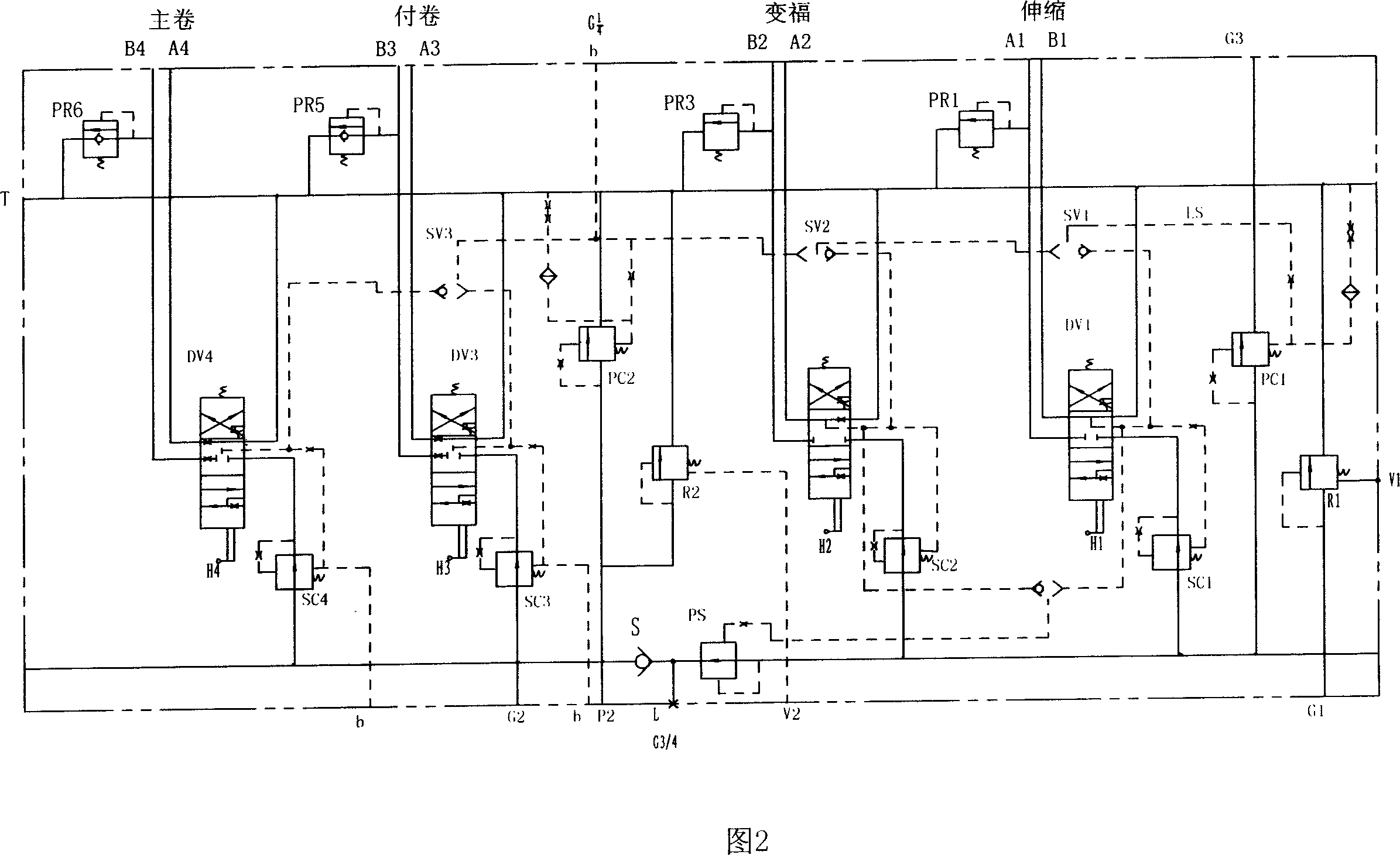

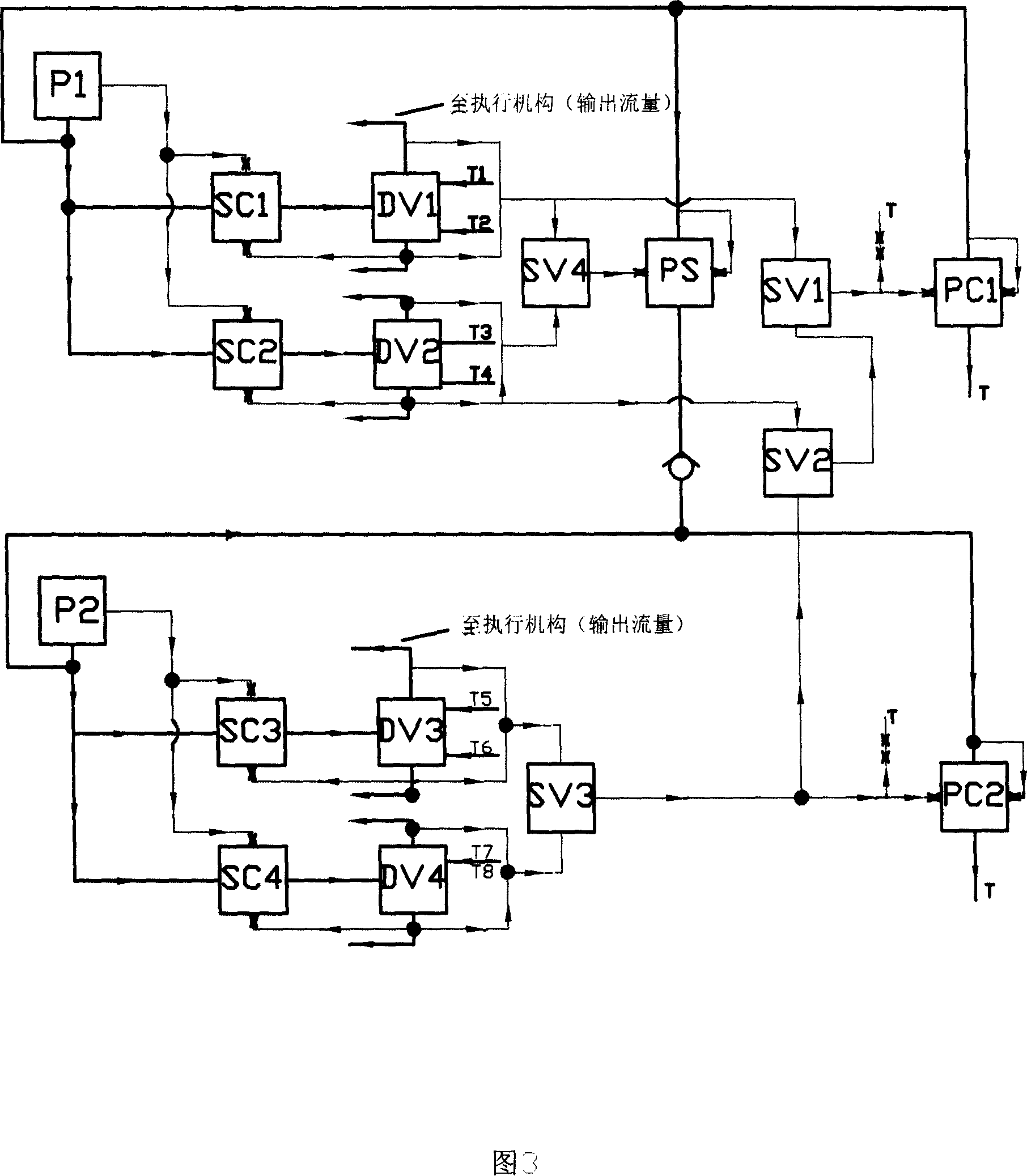

[0048] Fig. 1 to Fig. 11 show the embodiment of the multi-way proportional control valve with load-sensing double-pump confluence of the present invention.

[0049] Figure 1 is the hydraulic schematic diagram of the load-sensitive multi-channel proportional control valve operated by external hydraulic control; Figure 2 is the hydraulic schematic diagram of the load-sensitive multi-channel proportional control valve with manual control, and the main code names in the figure are explained as follows :

[0050] P1 and P2 are the input ports of pump 1 and pump 2 displacement

[0051] R1 and R2 are the main relief valves at the respective outlets of pump 1 and pump 2, which are called safety valves in this example;

[0052] PC1 and PC2 are the pressure compensators at the respective outlets of pump 1 and pump 2, which are called diverter valves i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap