Electrolytic capacitor with terminal

A technology for electrolytic capacitors and capacitors, applied to capacitor terminals, capacitor parts, etc., can solve problems such as increased contact resistance, difficulty in visually confirming the presence or absence of gasket 9, and discrete contact resistance values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

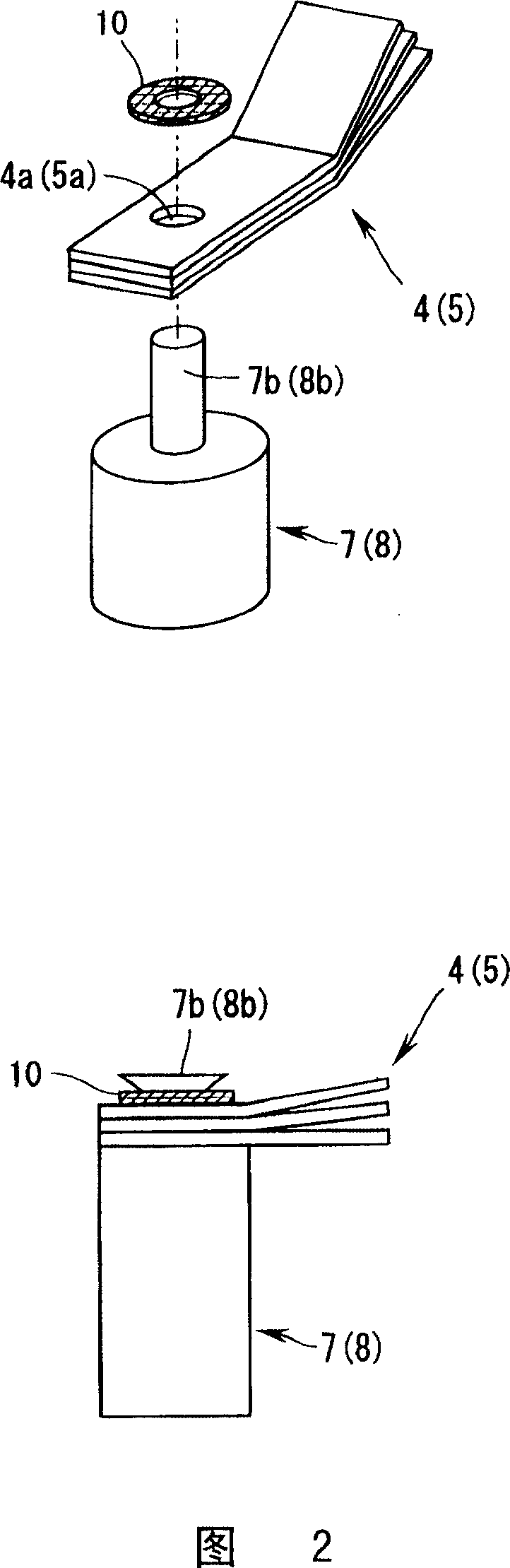

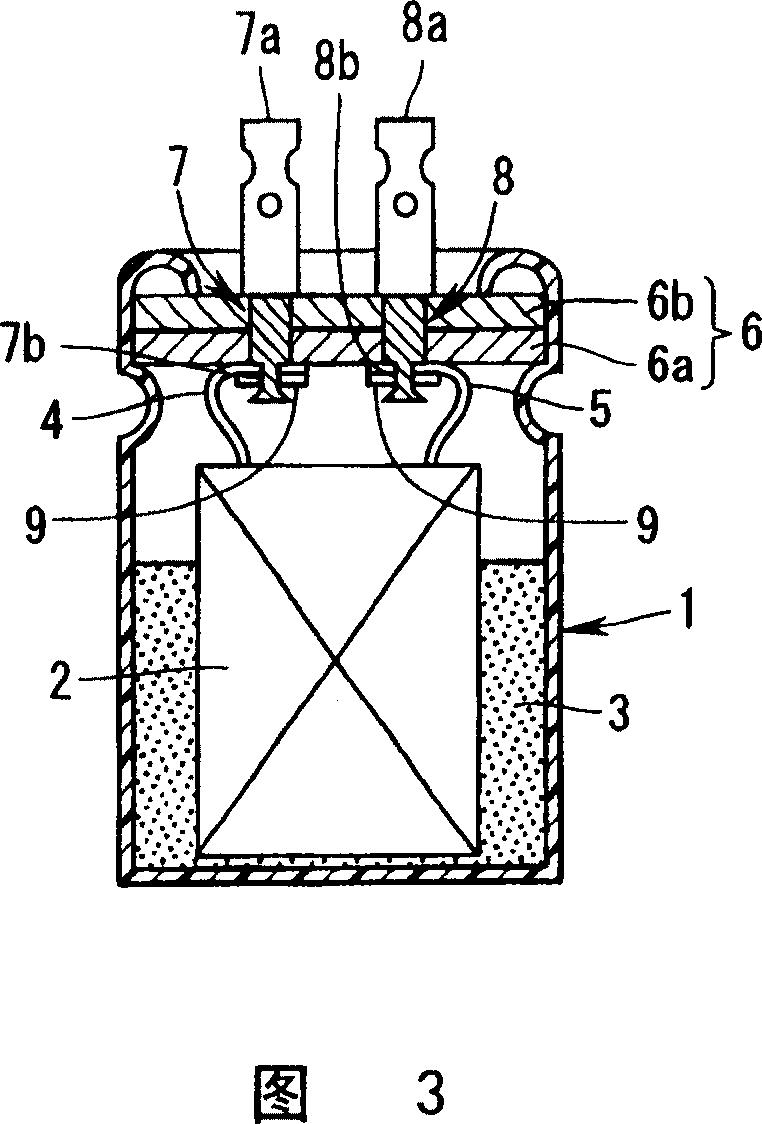

[0024] Hereinafter, preferred embodiments of the present invention will be described with reference to FIG. 1 and FIG. 2 . 2 is an explanatory diagram for explaining the step of riveting the outer lead foil to the anode side rivet. The cathode side rivet is performed in the same way as the anode side. For this reason, the components on the cathode side rivet side are shown in in parentheses. In addition, the basic structure of the electrolytic capacitor with a terminal itself can be referred to the general structure diagram of FIG. 3 described above.

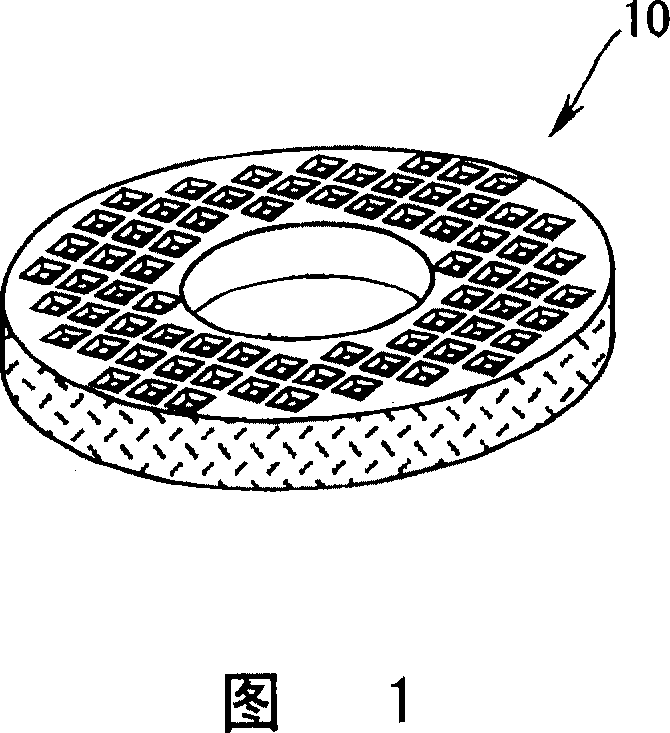

[0025] First, referring to the enlarged perspective view of FIG. 1 , the spacer 10 used in the present invention is made of aluminum, and is subjected to uneven surface processing. The non-flat surface processing refers to forming either one of the concave portion and the convex portion, or both the concave portion and the convex portion on a flat surface.

[0026] As an example, a plurality of holes (recesses) can be formed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com