Light emitting diode and manufacturing method thereof

A technology for light-emitting diodes and a manufacturing method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as low light extraction efficiency, and achieve the effects of reducing total reflection and improving light extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

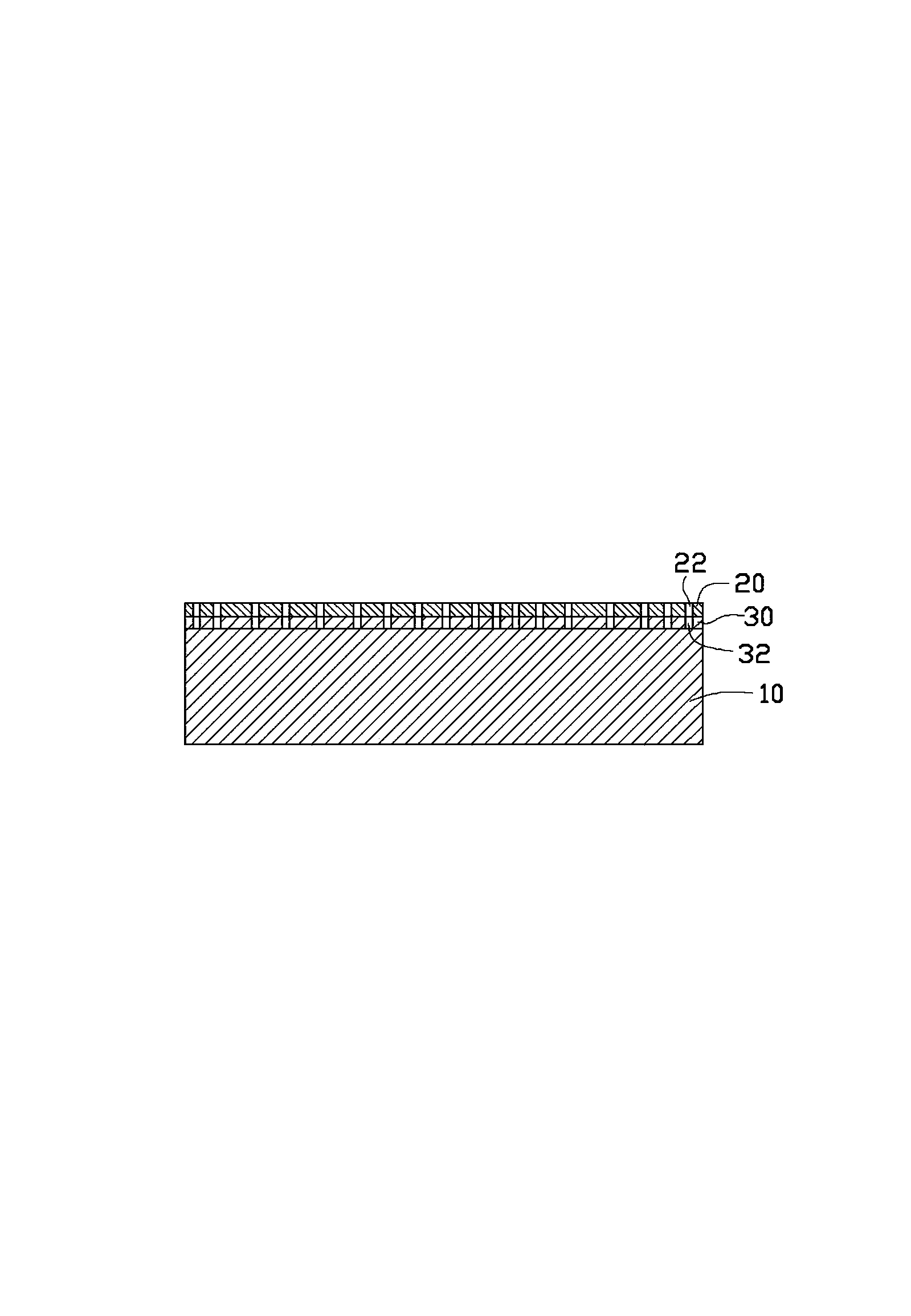

[0014] Please refer to Figure 1 to Figure 9 As shown, a method for manufacturing a light emitting diode 100 provided by an embodiment of the present invention includes the following steps:

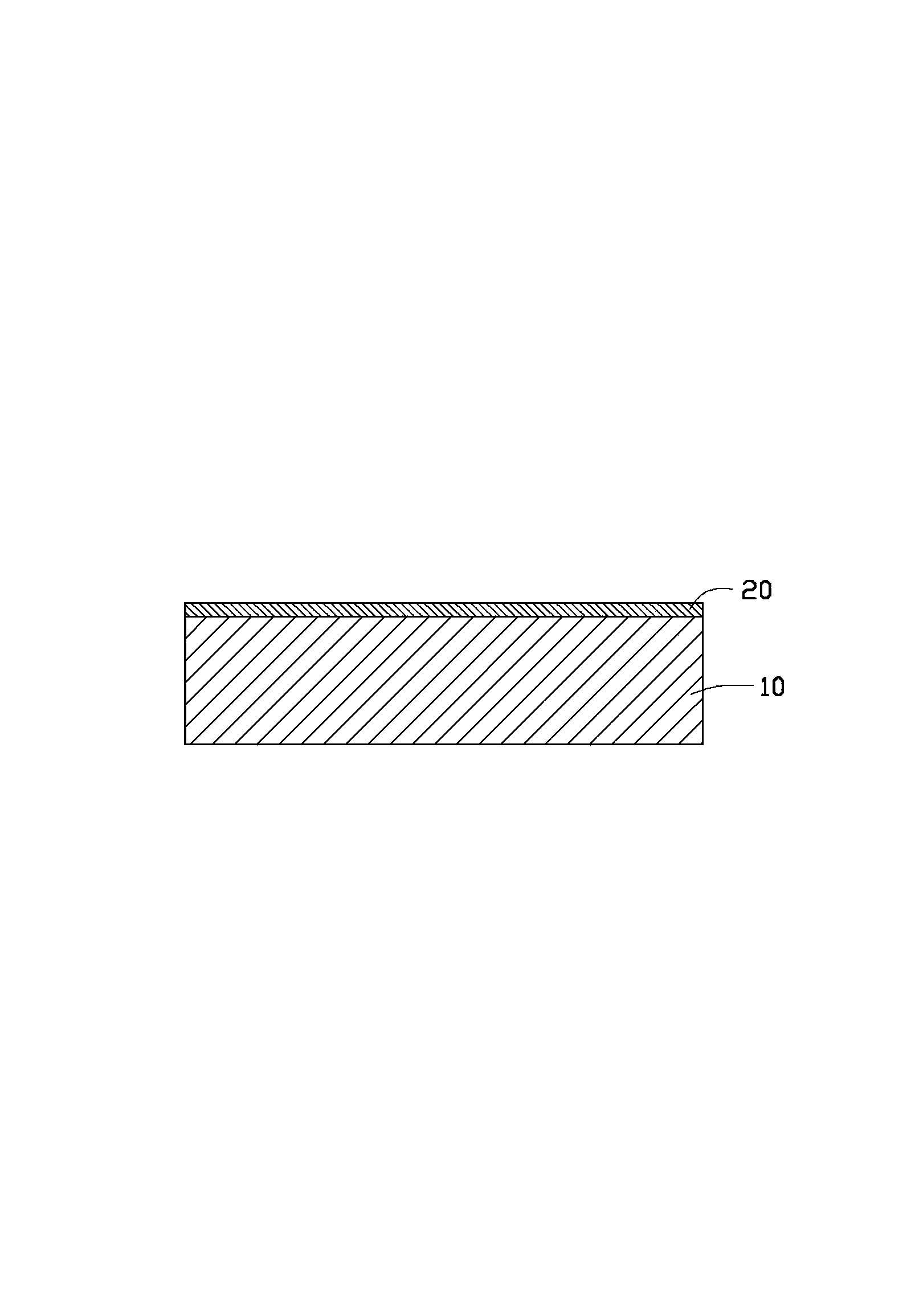

[0015] In the first step, a substrate 10 is provided, and a mask 20 is formed on the substrate 10 so that the mask 20 covers the substrate 10 (please refer to figure 1 ).

[0016] In this embodiment, the material of the substrate 10 is sapphire, and the material of the mask 20 is polysilicon. The mask 20 is grown on the upper surface of the substrate 10 by chemical vapor deposition (CVD), and the thickness of the mask 20 is 2 micrometers.

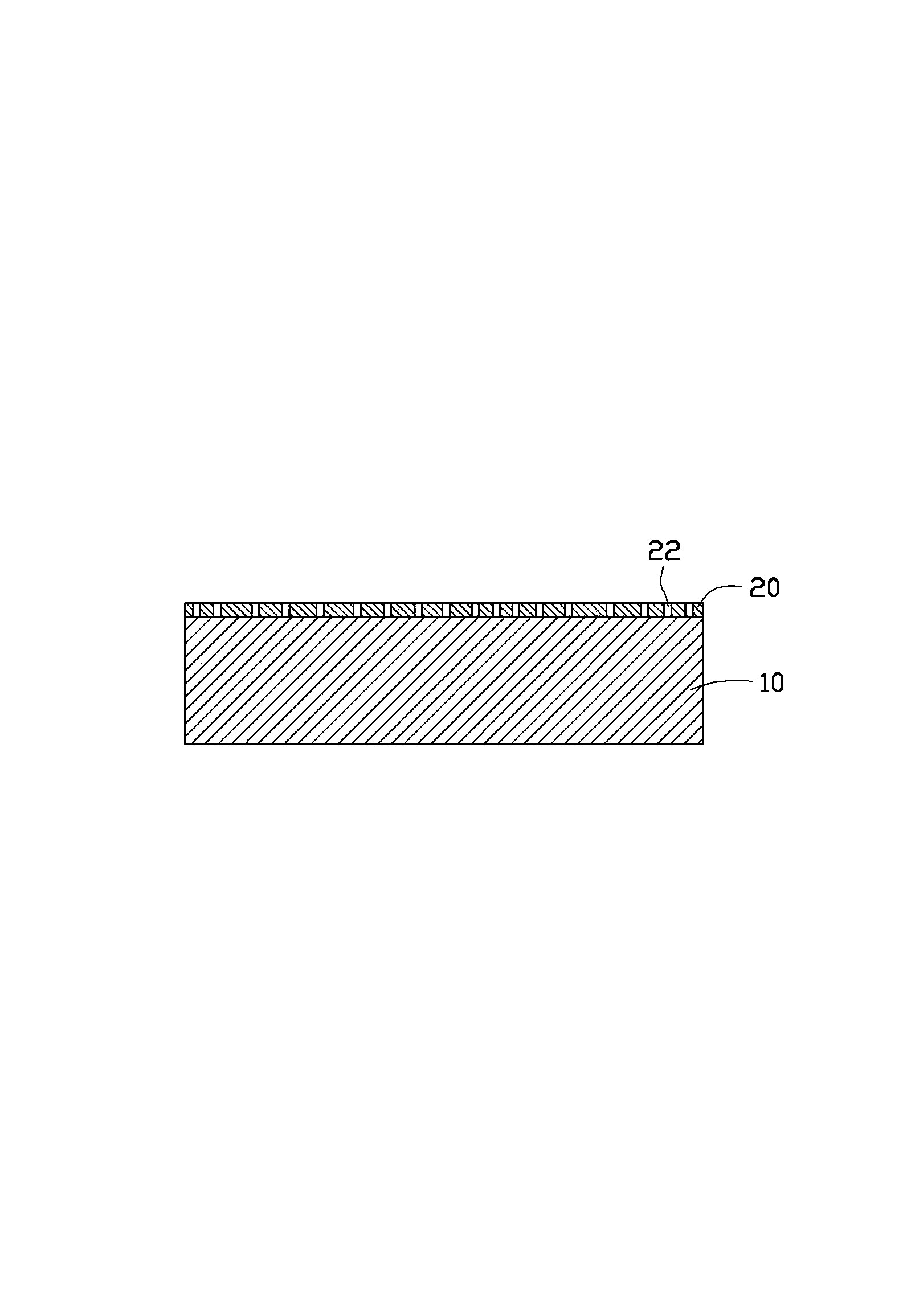

[0017] In the second step, the mask 20 is patterned and etched. After the mask 20 is etched, a plurality of nanoscale holes 22 are formed through the mask 20 to partially expose the substrate 10 below the mask 20 (please refer to figure 2 ).

[0018] In this embodiment, this step uses a mixed liquid of hydrofluoric acid and nitric acid to etch the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com