Refiner

A refiner and refiner technology, applied in pulp beating/refining methods, food science, applications, etc., can solve the problems of reducing the production capacity of the refiner, losing parallelism of segments, and loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

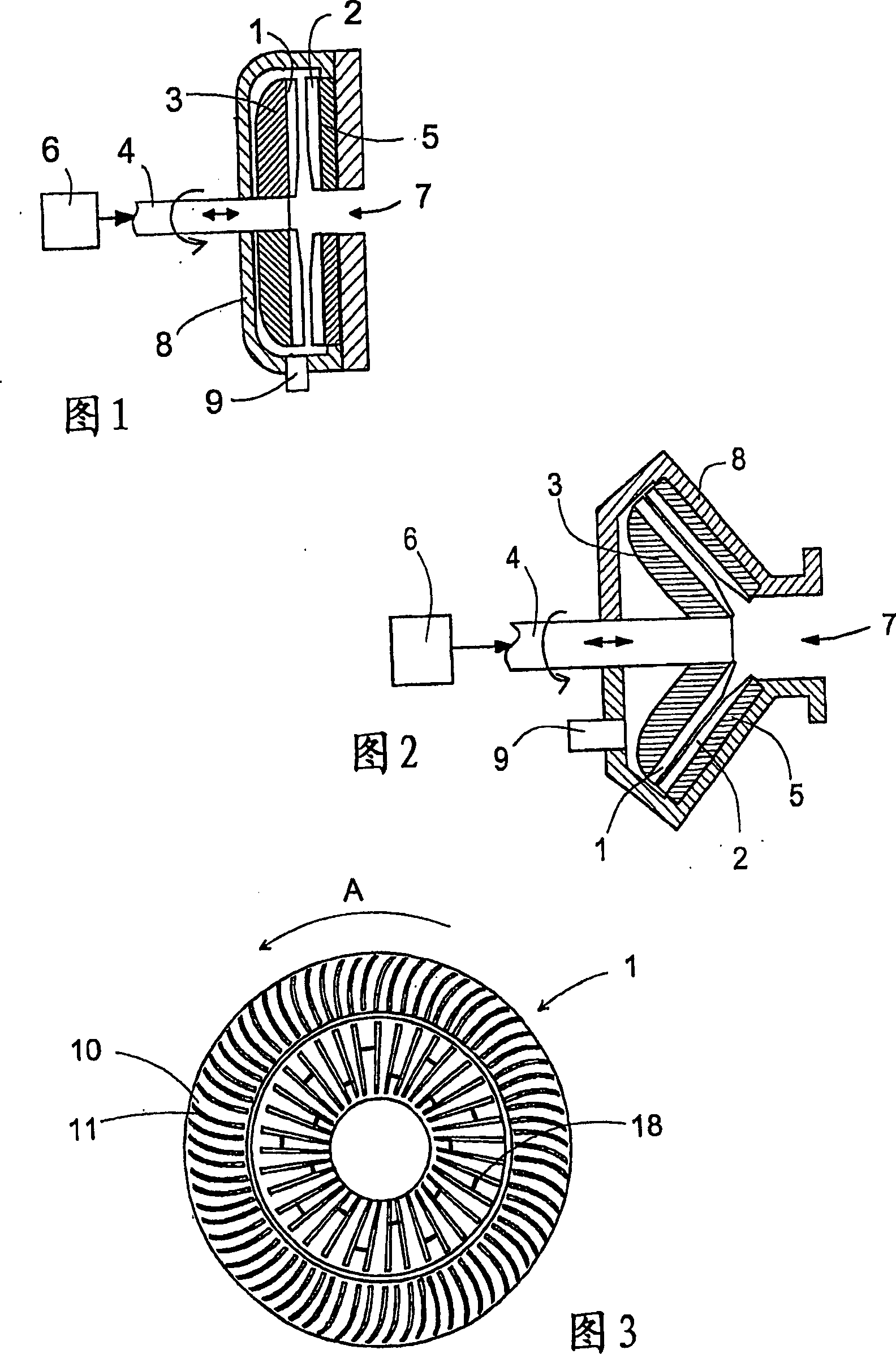

[0018] Fig. 1 is a schematic side sectional view of a conventional disc refiner. A disc refiner comprises two disc-shaped refining surfaces 1 and 2 which are arranged coaxially with respect to each other. In the present embodiment, one of the refining surfaces 1 is located on a rotating grinding disc 3 and rotates about an axis 4 . In this case, the other refining surface 2 is located on a fixed grinding disc 5, ie on the stator. The refining surfaces 1 and 2 on the grinding discs 3 and 5 can be formed directly on the discs or from separate refining segments in a manner known per se. Furthermore, Fig. 1 shows a loader 6 connected to the grinding disc 3 via a shaft 4, so that it can be pushed towards the grinding disc 5 to adjust the opening between them. The grinding disc 3 is rotated about an axis 4 in a manner known per se by means of an electric motor, not shown in the figures for the sake of clarity.

[0019] The material containing wood fibers to be disintegrated is fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com