Radiating structure of power battery for hybrid power automobile

A power battery pack and heat dissipation structure technology, which is applied in the direction of electric vehicles, secondary batteries, circuits, etc., can solve the problems of inconvenient real-time discovery, difficult to ensure the consistency of the temperature field of the battery pack, and inconvenient processing, so as to facilitate the whole vehicle The effect of installation layout, consistency, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

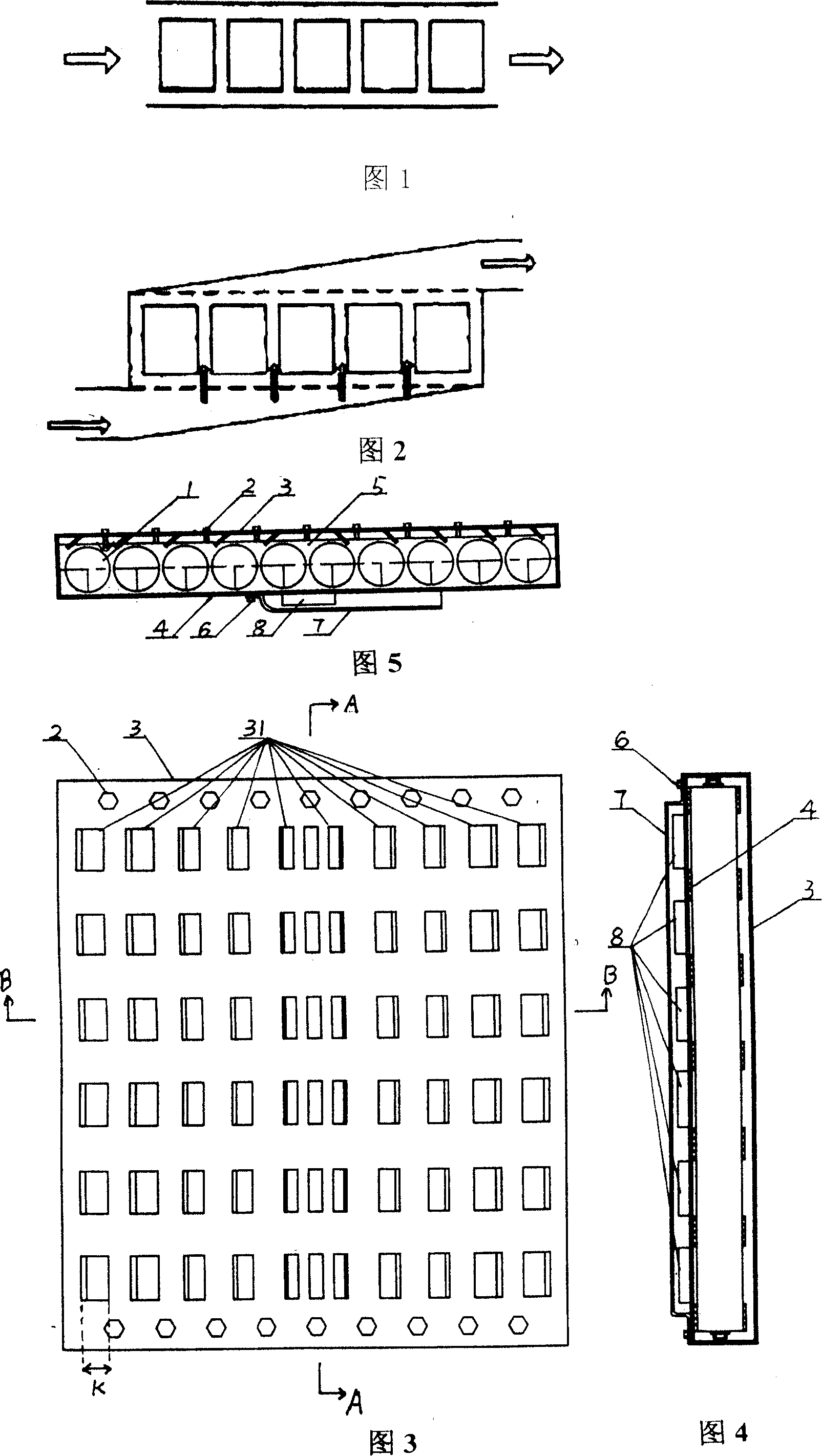

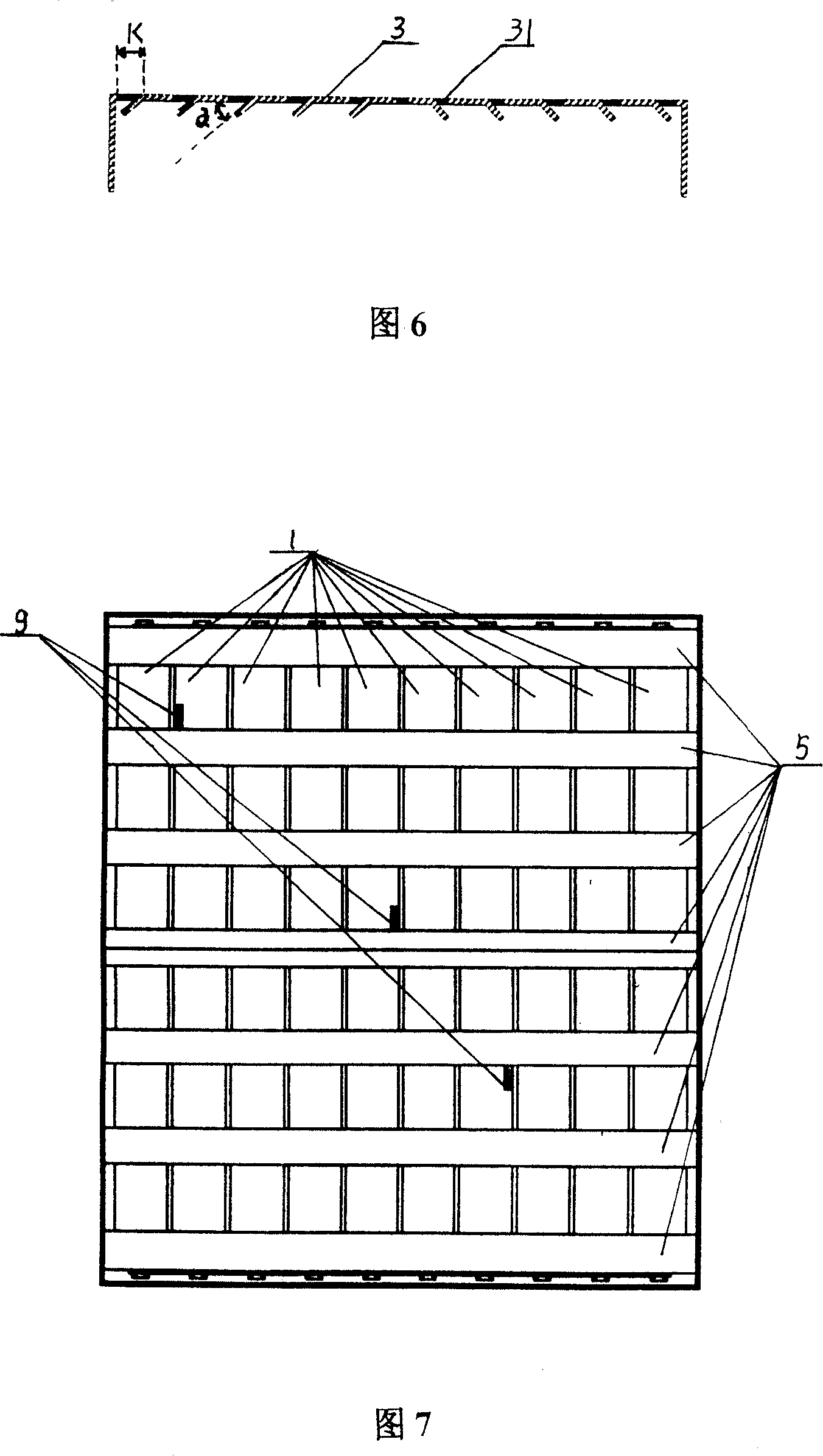

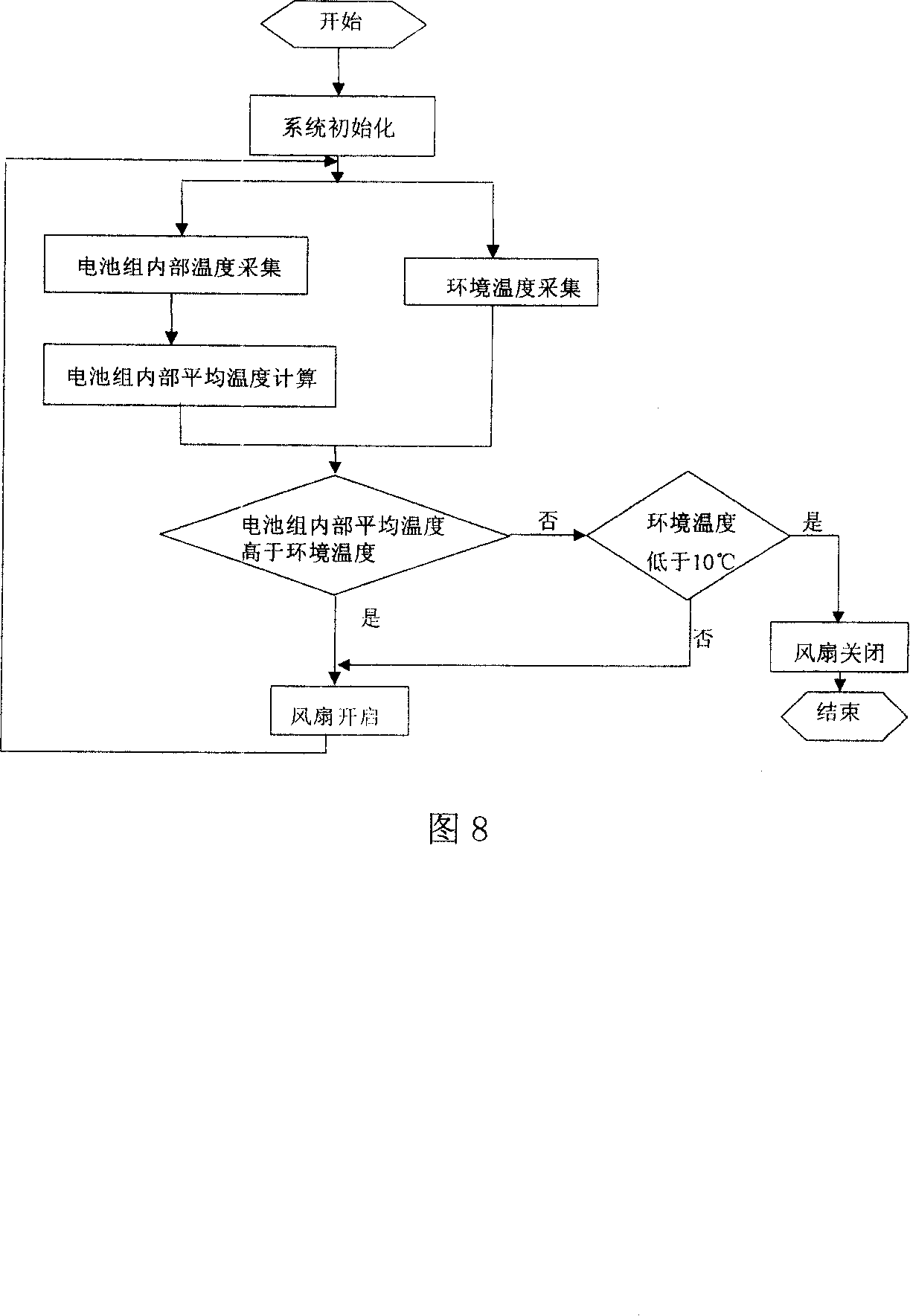

[0016] This cooling structure is shown in Fig. 3, Fig. 4 and Fig. 5, and it comprises accumulator group 1, air intake guide cover plate 3, accumulator support plate 5, accumulator bottom plate 4 and exhaust fan 8. The battery pack 1 is supported by the battery support plate 5 and is fixed on the battery base plate 4 . The wind guide cover plate 3 covers the battery pack 3 from the top and is fixed with the battery support plate 5 by connecting bolts 2 . It can be seen from Fig. 7 that there is an air intake guide groove 31 obliquely on the position corresponding to each single battery on the air intake guide cover plate 3, and the notches of the air intake guide groove 31 are obliquely opposite to the two rows of batteries. The gap between the groups, and the slot width K and diversion angle α of the air intake guide slot 31 gradually increase along the center of the battery pack to both sides, the slot width is between 10-20mm, and the intake guide slot 31 is 15-25° with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com