Three-dimensional sequential effect maximization method for multi-stage turbomachine

A turbine and timing technology, applied in the direction of blade support components, mechanical equipment, engine components, etc., can solve the problems of not being able to maximize the use of two-dimensional timing, and achieve the effects of engineering practicality, efficiency improvement, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

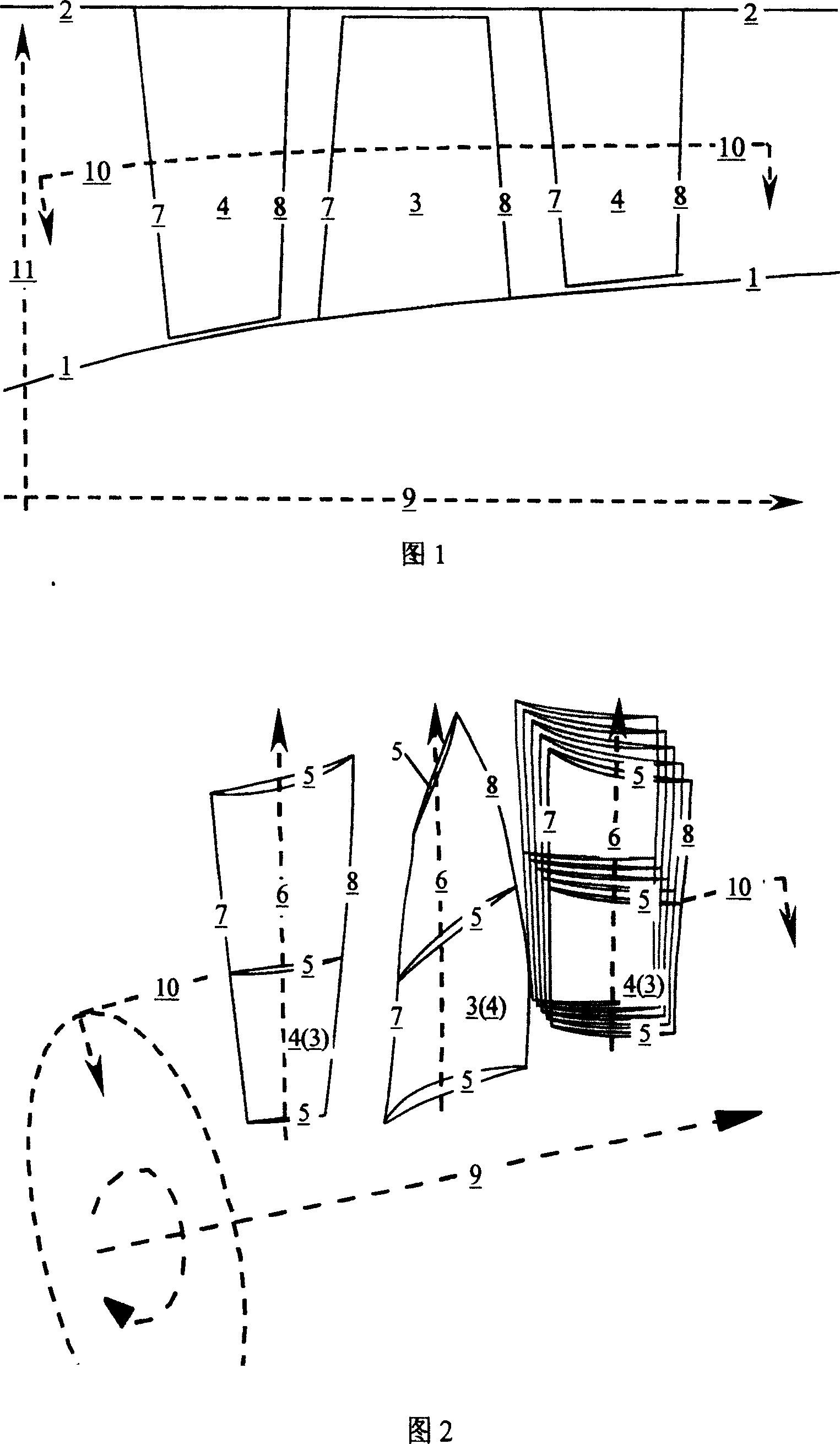

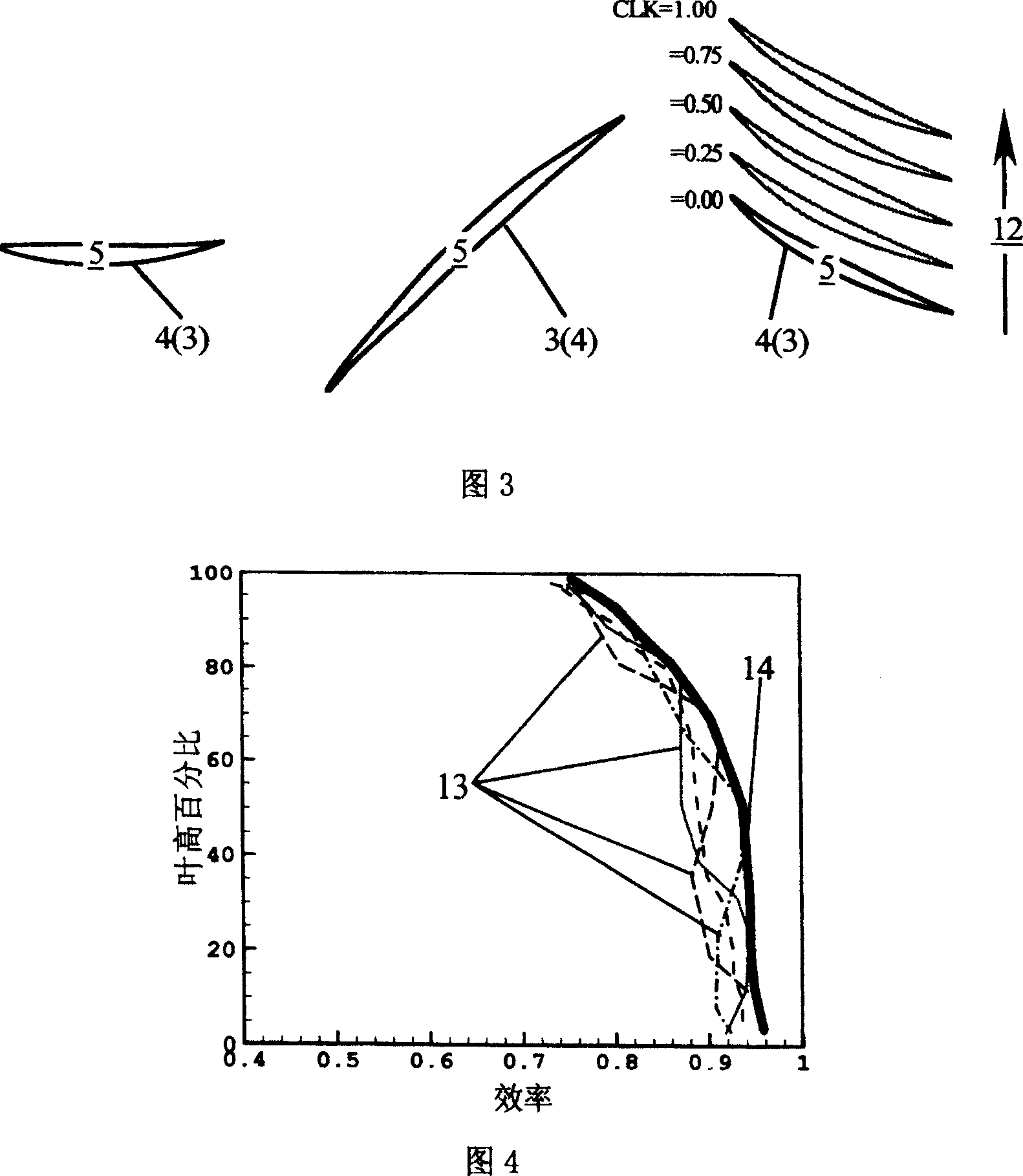

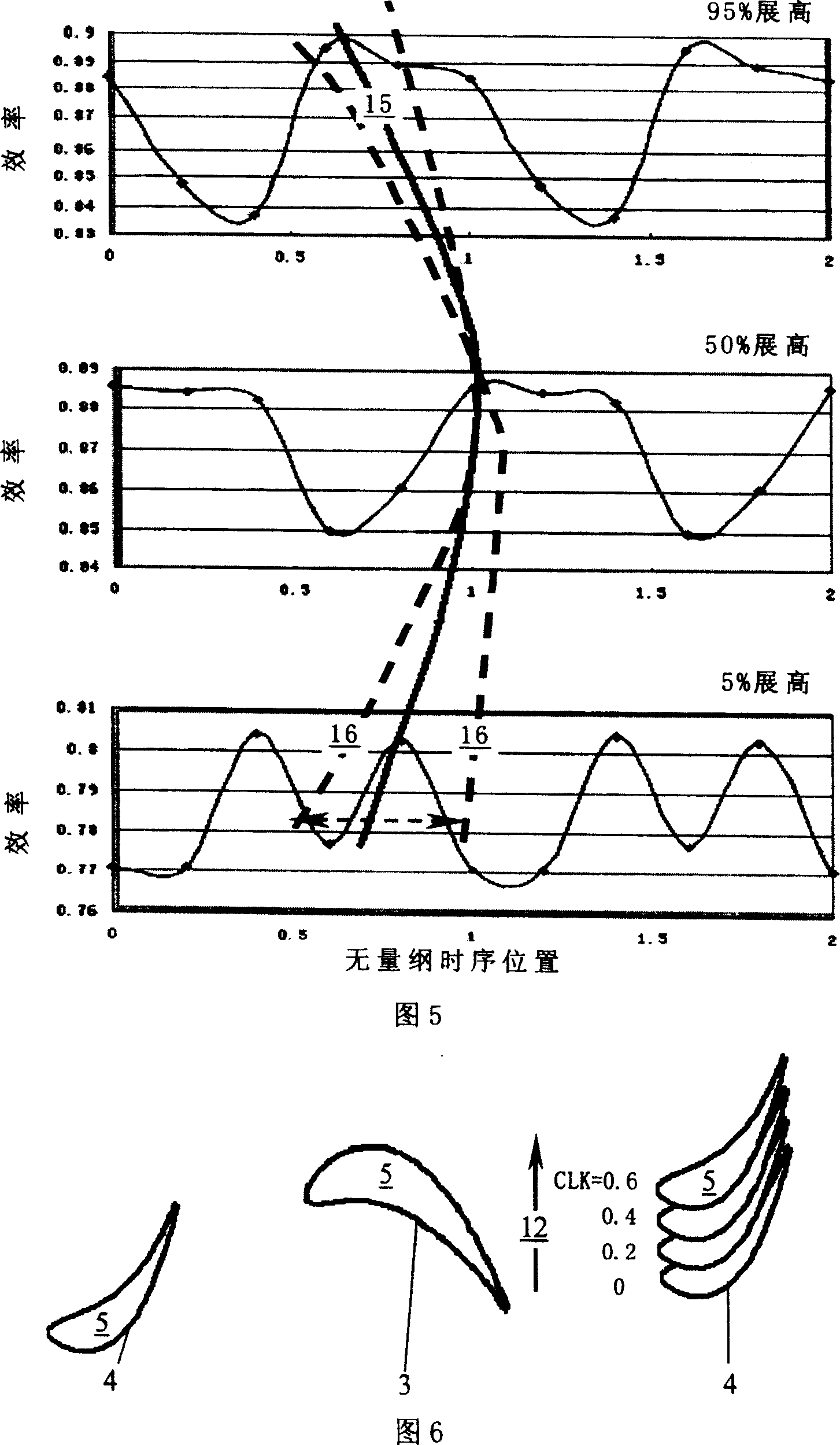

[0034] It should be noted that the same numbers in the drawings are used to represent the same characteristics, and some numbers have an underline to indicate that the position of the number is exactly the part to be represented.

[0035] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

[0036] Referring to Figure 6, a certain 1.5-stage (static / rotation / static form, three rows of blades) axial flow turbine blades, in the process of re-stacking to achieve the maximum three-dimensional timing goal, includes the following steps:

[0037] 1) Accurate unsteady flow field time for a multi-stage turbine with three-row blade combination at 5 time series positions 0, 0.2, 0.4, 0.6, 0.8 (with the dimensionless value of the grid pitch, Figure 6 shows a certain spanwise section) simulation;

[0038] 2) Analyze the time-average efficiency of each spanwise section of the multi-stage turbine in each sequence position in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com