Chip checking system and method

An inspection system and inspection method technology, applied in electrical components, semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, etc., can solve the problems of product quality damage, futile follow-up processes, inconvenient inspection, etc., to improve the finished product. efficiency, shortening inspection time, and reducing process burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

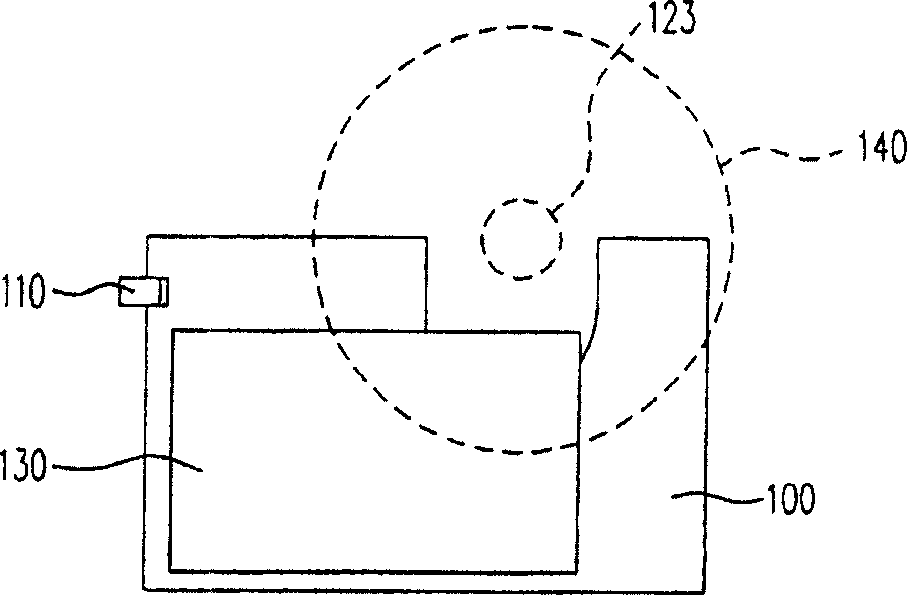

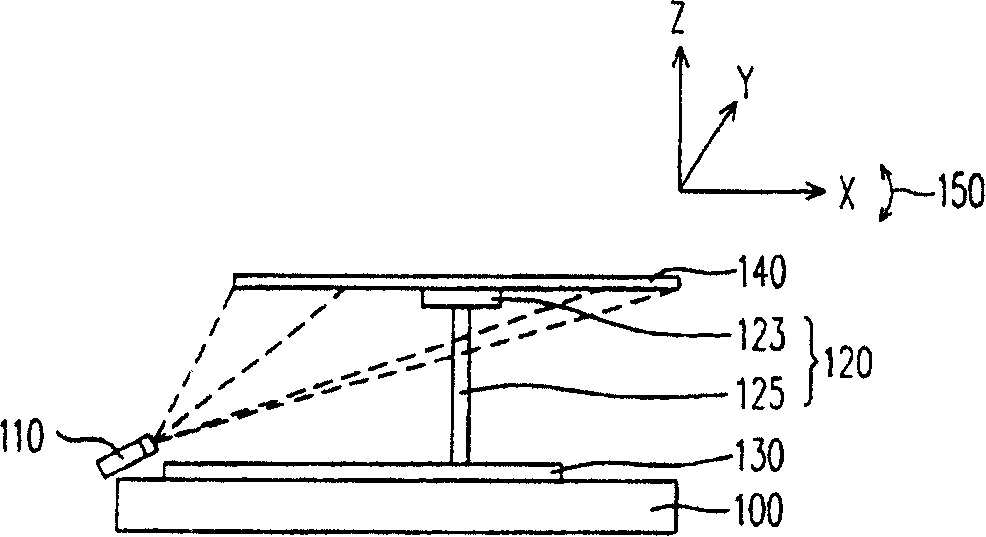

[0033] Figure 1A It is a top view of a wafer inspection system according to an embodiment of the present invention. Figure 1B It is a side view of a wafer inspection system according to an embodiment of the present invention when inspecting wafers.

[0034] Please refer to Figure 1A and Figure 1B , the present invention proposes a wafer inspection system, which is composed of, for example, a light source 110 , a wafer carrier 120 and a reflective element 130 . The wafer carrying device 120 is used for carrying a wafer 140 . The light source 110 is configured corresponding to the wafer carrier 120 , for example, it is disposed beside the wafer carrier 120 to illuminate the backside of the wafer 140 . The reflective element 130 is configured corresponding to the wafer carrier 120 , for example, is disposed under the wafer carrier 120 to reflect the backside of the wafer 140 .

[0035] Wherein, the light source 110 is, for example, a light emitting diode, an organic light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com