Technique for improving solid content of raw pulp

A process method and slurry technology, applied in chemical instruments and methods, inorganic chemistry, alumina/aluminum hydroxide, etc., can solve problems such as unreachable, achieve the effects of reducing quantity, improving technical indicators, and saving engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

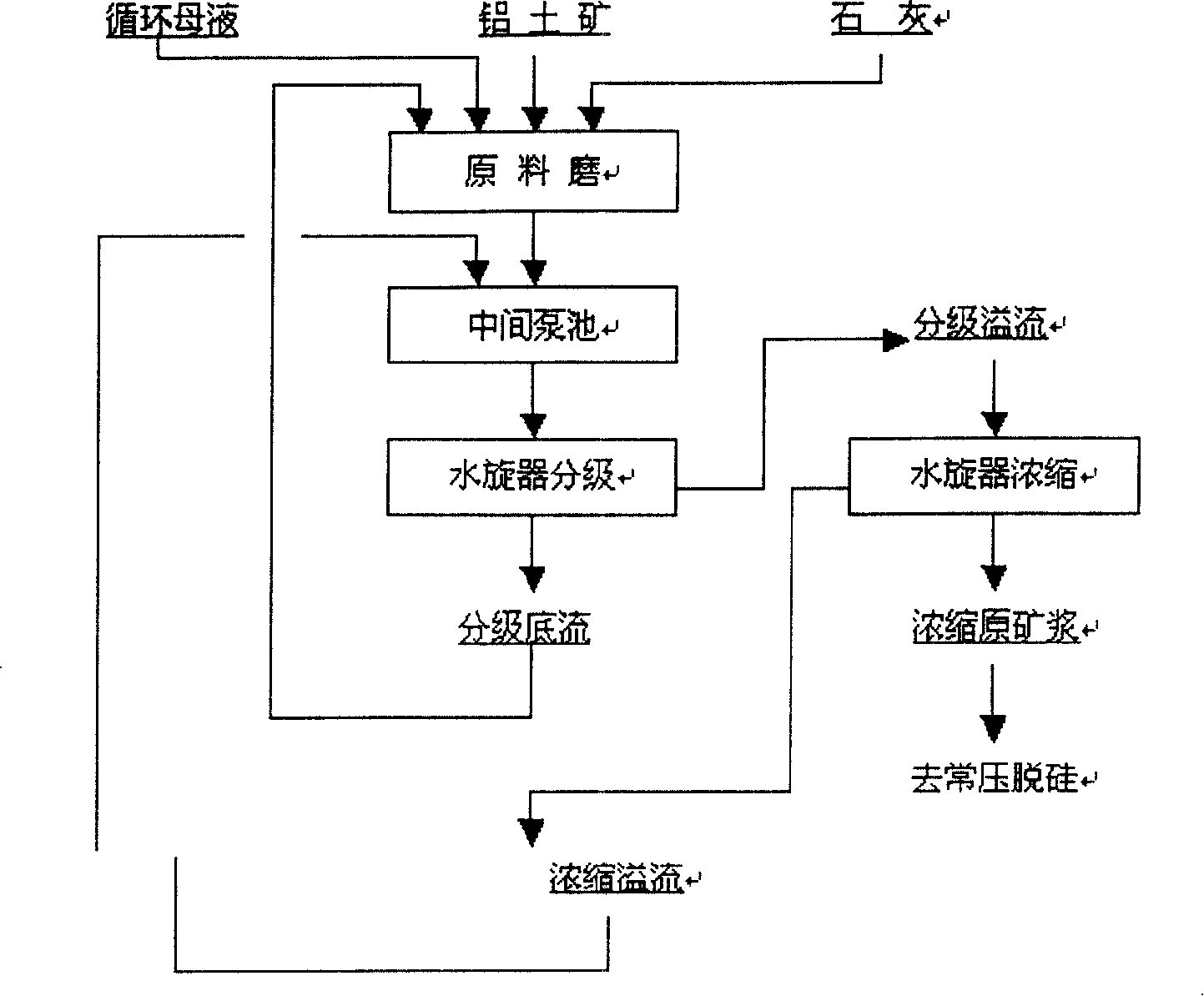

[0016] Embodiment 1 of the present invention: In the process after hydrocyclone grading, a hydrocyclone concentration device is set; the specification of hydrocyclone is φ300~500; The raw ore pulp that comes out has a solid content of 250-300g / l and a pressure of 0.1-0.12MPa, and is sent to the additional hydrocyclone for concentration; the concentrated underflow raw ore pulp has a solid content of 600-800g / l, As the product of this process is sent to the normal pressure desiliconization process, the overflow after concentration by the hydrocyclone has a solid content of 100-150g / l, and the overflow returns to the intermediate pump pool for circular classification and concentration. Since the solid content of raw ore pulp is greatly increased, the number of subsequent atmospheric pressure desilication tanks can be appropriately reduced.

Embodiment 2

[0017] Embodiment 2 of the present invention: the raw ore pulp overflow product obtained in the existing hydrocyclone classifying unit (or spiral classifier) of the raw material mill in the alumina factory, its solid content is 200~300g / l, enters the middle raw ore pulp tank, Use pumps and pipelines to send the materials in the intermediate raw ore slurry tank to one (group) or several (groups) hydrocyclone concentration devices (determine the number of units and groups according to the production scale), and the hydrocyclone concentration device feeds The pressure is 0.1-0.12MPa, the specification of the hydrocyclone is φ300-500, and the solid content of the concentrated underflow raw ore pulp reaches 600-800g / l. As the product of this process, it is sent to the normal pressure desiliconization process. The solid content of the fluid is 100-150g / l, and the overflow is returned to the intermediate pump pool for circulation classification and concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com