Process for preparing magnesium diboride superconductor

A magnesium diboride and superconductor technology, applied in the field of magnesium diboride superconductor preparation, can solve the problems of lowering the transition temperature of magnesium diboride, low critical current density of magnesium diboride, poor connection performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

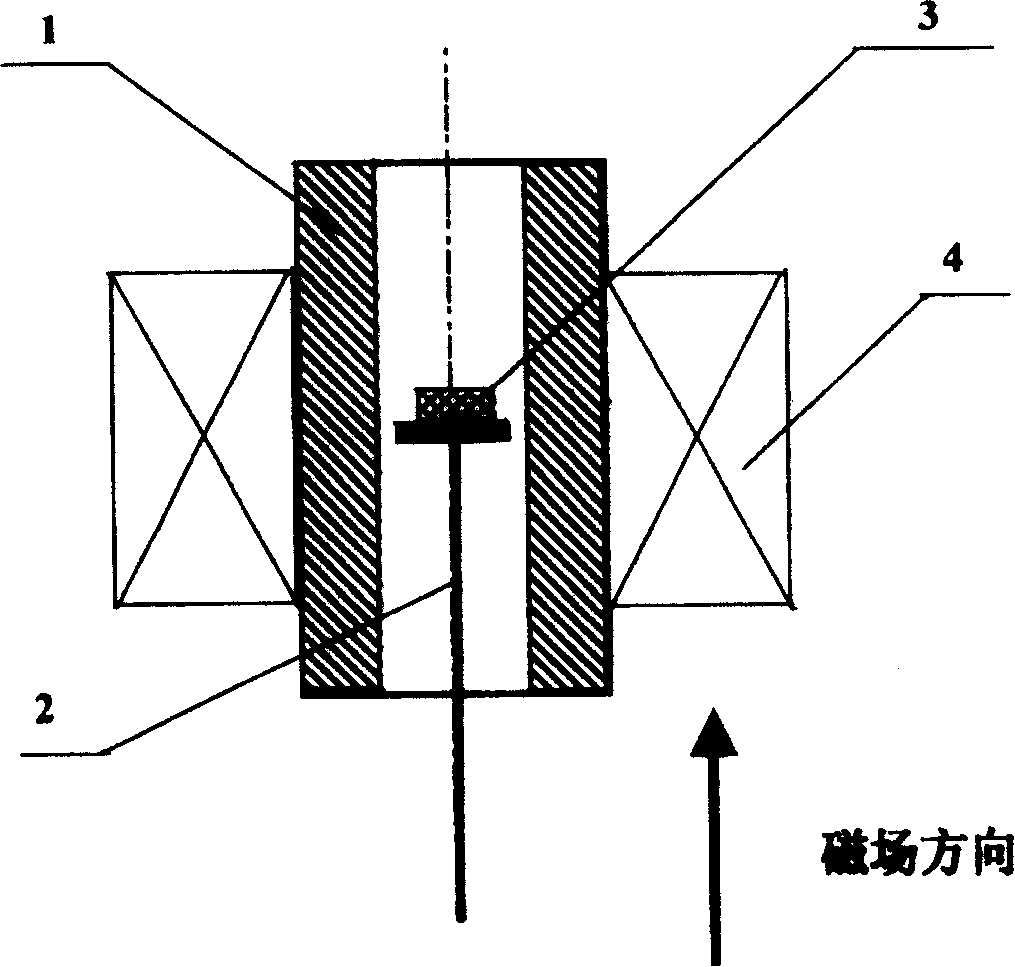

[0013] The superconducting magnesium powder and superconducting boron powder prepared according to the stoichiometric ratio of 0.7:2 are mixed evenly and put into the mold, pressed into small pieces with a diameter of 5 mm and a thickness of 5 mm, wrapped and sealed with Ta foil, and the block sample 3 placed on the sample holder 2 in the superconducting strong magnetic field heat treatment furnace 1 with an Ar atmosphere. Turn on the power of the strong magnetic field device 4 and make its magnetic field strength reach 0.5 Tesla, and then turn on the power of the heat treatment furnace 1. After the heat treatment furnace 1 was kept at a temperature of 950° C. for 3 hours, the power of the heat treatment furnace 1 was turned off, and the sample was cooled to room temperature with the heat treatment furnace, and the sample was taken out to obtain a magnesium diboride superconducting block.

Embodiment 2

[0015] The superconducting magnesium powder and the superconducting boron powder prepared according to the stoichiometric ratio of 1:2 are evenly mixed and put into a mold, pressed into small pieces with a diameter of 5 mm and a thickness of 5 mm, wrapped and sealed with Ta foil, and the block sample 3 Placed on the sample holder 2 in 1 of the superconducting high magnetic field heat treatment furnace with Ar atmosphere. Turn on the power of the strong magnetic field device 4 and make its magnetic field strength reach 3 Tesla, and then turn on the power of the heat treatment furnace 1. After the heat treatment furnace 1 was kept at a temperature of 600° C. for 3 hours, the power of the heat treatment furnace 1 was turned off, and the sample was cooled to room temperature with the heat treatment furnace, and the sample was taken out to obtain a magnesium diboride superconducting block.

Embodiment 3

[0017] The superconducting magnesium powder and the superconducting boron powder prepared according to the stoichiometric ratio of 0.9:2 are evenly mixed and put into a mold, pressed into small pieces with a diameter of 5 mm and a thickness of 5 mm, wrapped and sealed with Ta foil, and the block sample 3 Placed on the sample holder 2 in 1 of the superconducting high magnetic field heat treatment furnace with Ar atmosphere. Turn on the power of the strong magnetic field device 4 and make its magnetic field strength reach 6 Tesla, and then turn on the power of the heat treatment furnace 1. After the heat treatment furnace was kept at a temperature of 900°C for 3 hours, the power of heat treatment furnace 1 was turned off, the sample was cooled to room temperature with the heat treatment furnace, and the sample was taken out to obtain a magnesium diboride superconducting block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com