Cornering machine for glass tube transportation

A technology of turning machine and conveying mechanism, which is applied in glass transportation equipment, glass production, glass manufacturing equipment and other directions, can solve the problems that the glass tube cannot be turned horizontally, the carding machine cannot be placed vertically, and the production line can be increased, so as to improve the output of the kiln. and plant utilization, improving unit economic benefits, and the effect of small transmission driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

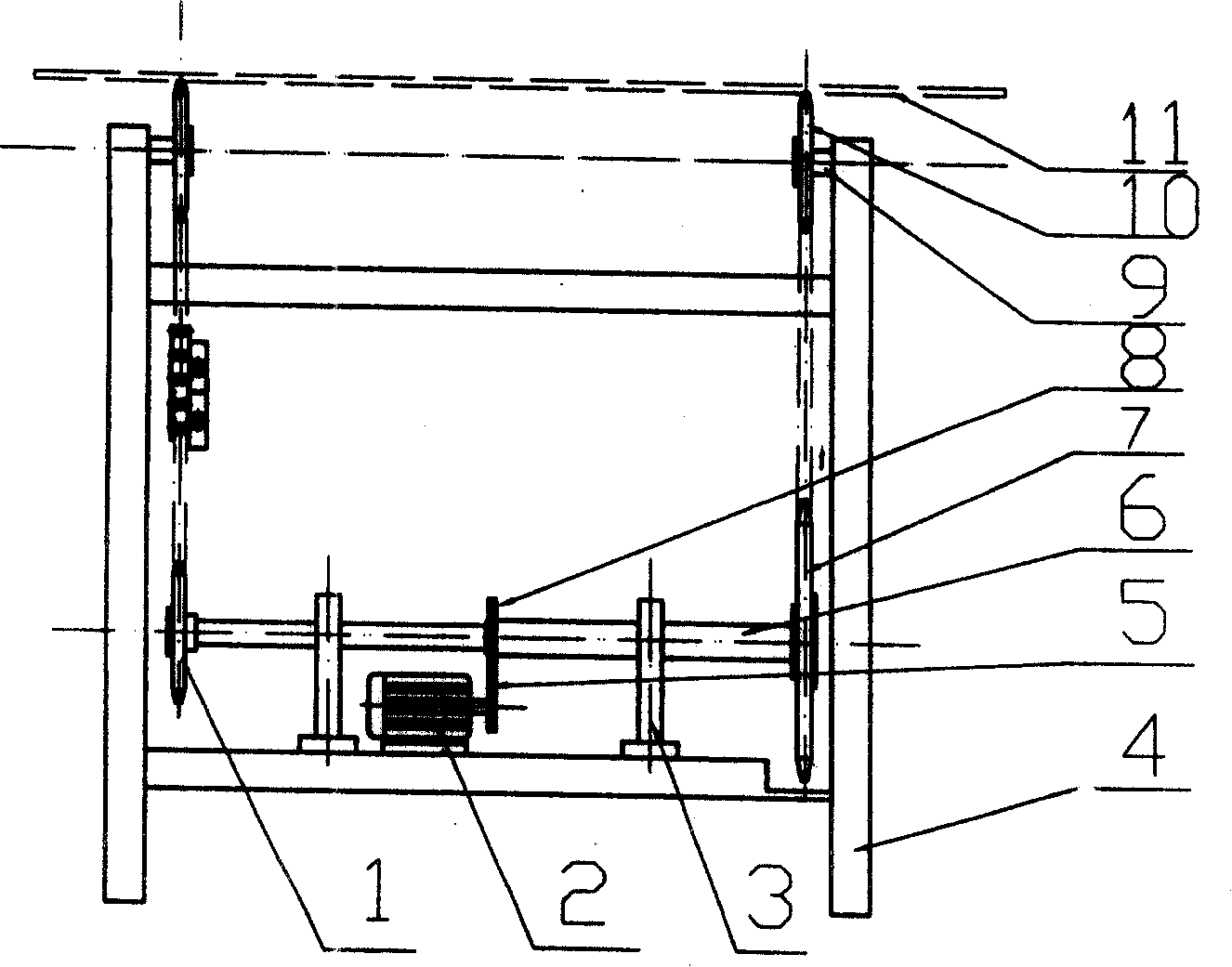

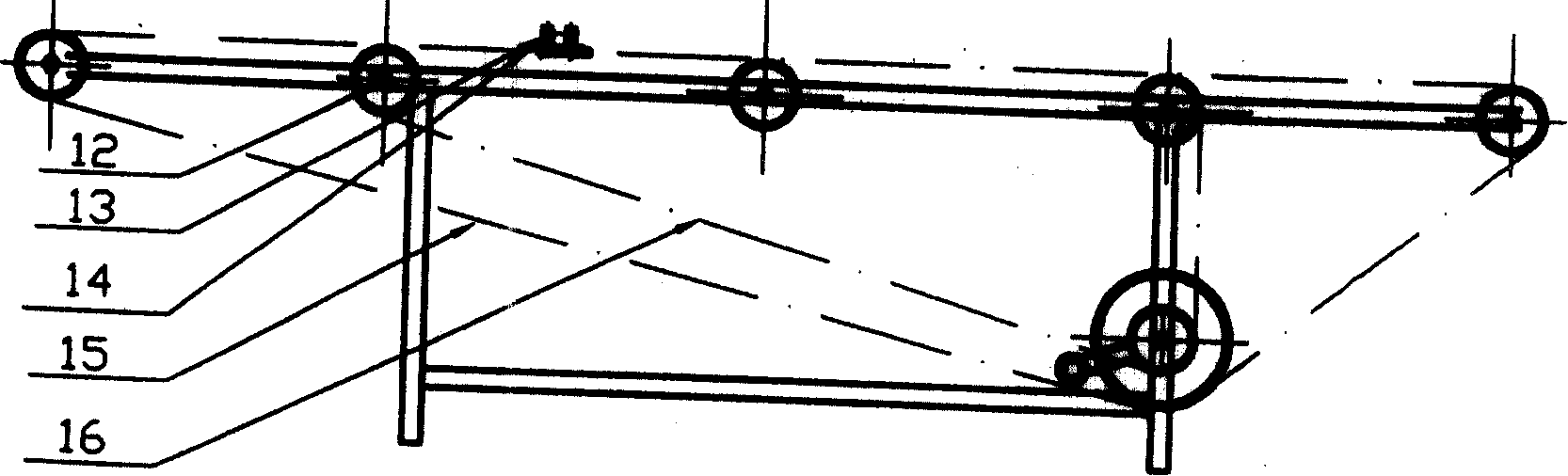

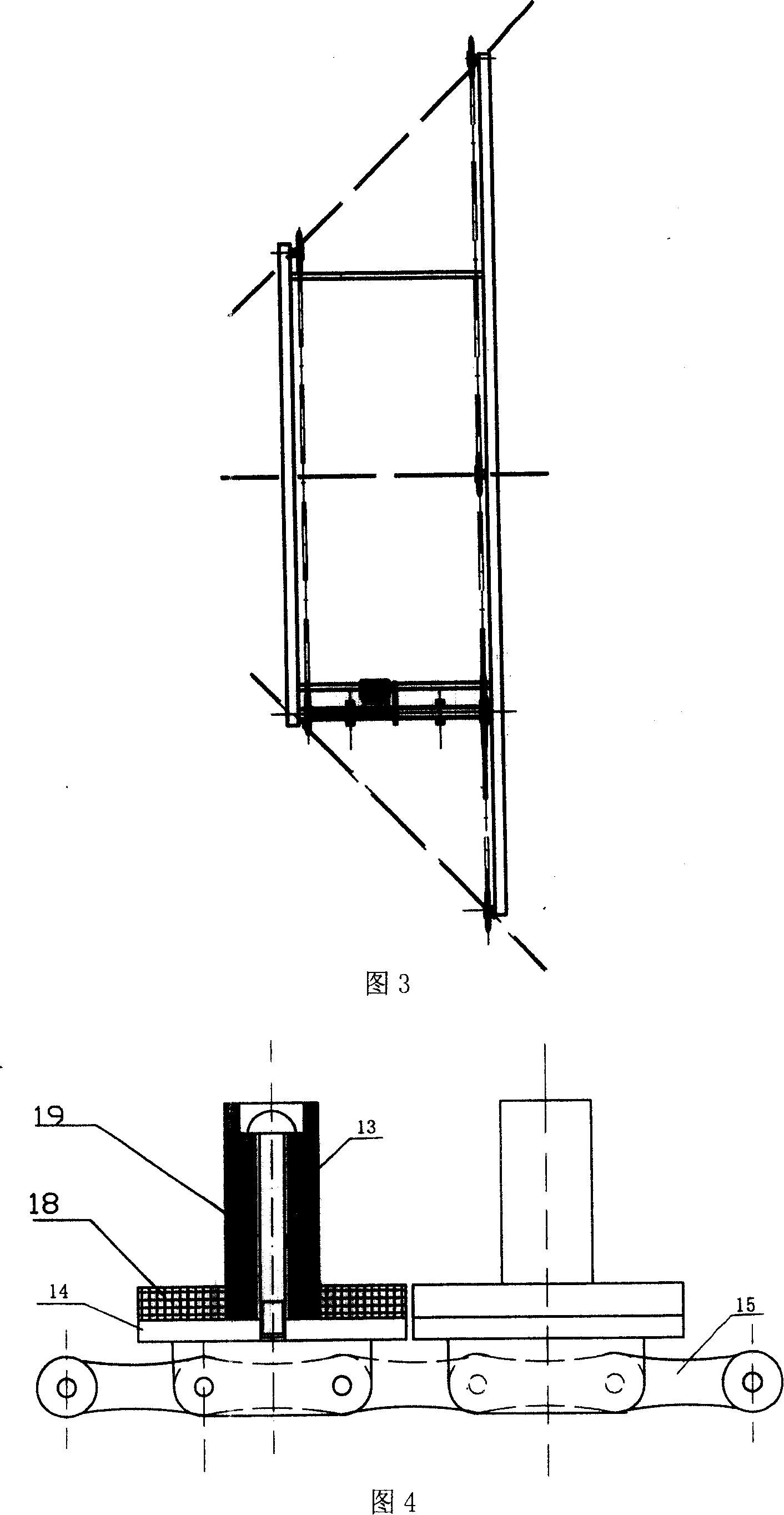

[0015] refer to figure 1 - Fig. 4, a glass tube conveying turning machine, including a bracket, a transmission mechanism and a conveying mechanism, a transmission mechanism and a conveying mechanism are installed on the bracket 4, and the transmission mechanism includes a motor 2 installed on the bracket 4, a sprocket support 9, Supporting wheel 10, transmission shaft support 3 and transmission shaft 6 installed thereon, small transmission sprocket 1, belt pulley 8 and large transmission sprocket 7 installed on the transmission shaft 6, the conveying mechanism includes 7 and the long conveyor chain 15 on the conveyor sprocket 17, the short conveyor chain 16 installed on the small transmission sprocket 1 and the conveyor sprocket 17, the glass tube supporting plate 14 and the baffle installed on the long conveyor chain and the short conveyor chain Block 13.

[0016] The top of support 4 is the structure that one side is long and one side is short, and long conveyor chain 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com