Near azeotropic ethanol dewatering process

A near-azeotropic ethanol technology, which is applied in the field of near-azeotropic ethanol water removal process, can solve the problems of product performance impact, non-competitiveness, high alcohol price, etc., and achieve reduced energy consumption, large-scale production of high-efficiency ethanol gasoline, and simplified The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

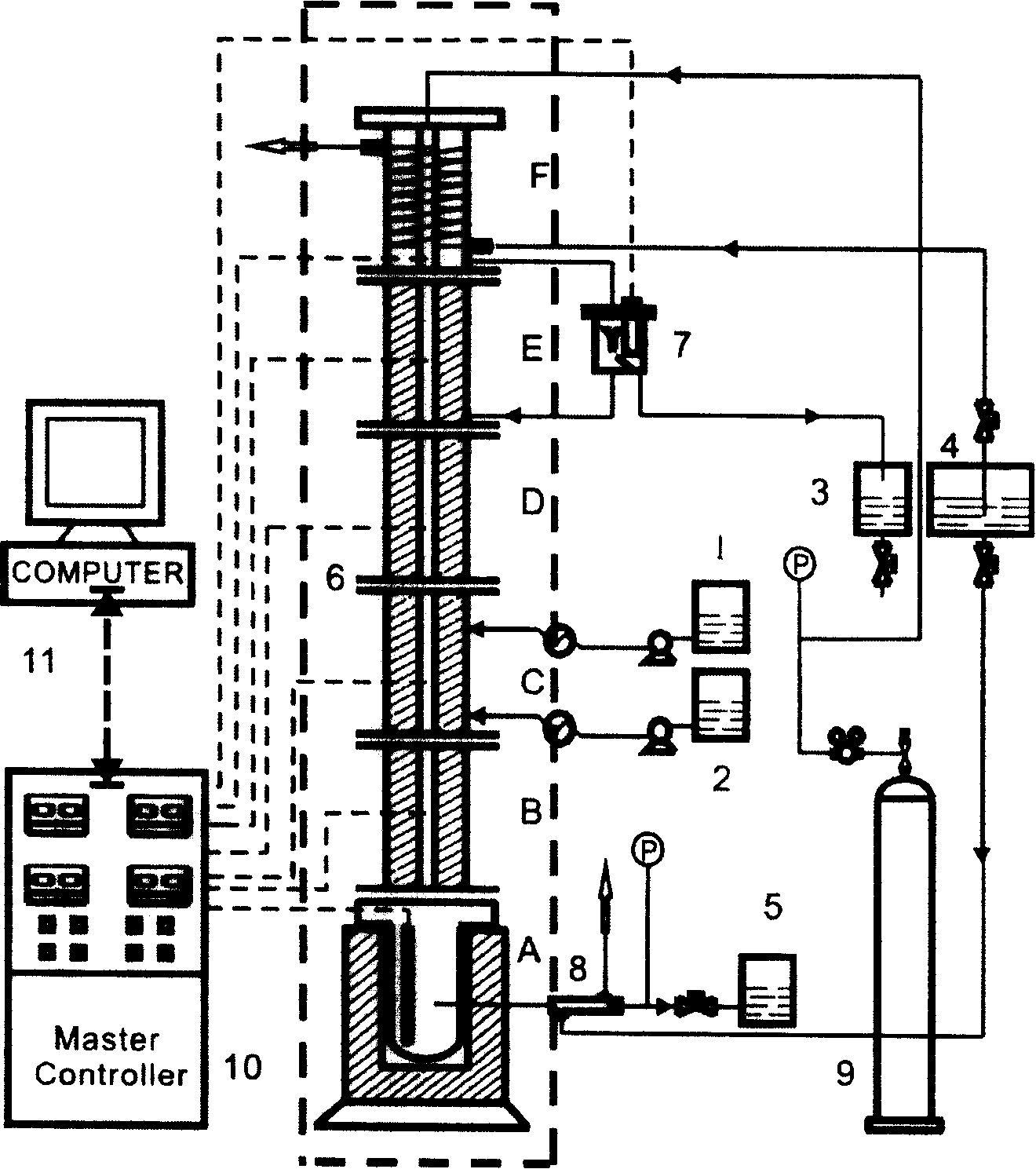

[0031] a. first fill the columnar solid acid S-54 resin catalyst filler in the reaction section C of the reactive distillation tower 6, add the ethanol-water mixture feed liquid of 700ml 85wt% in the tower still A;

[0032] b. Then the top of the tower is connected to N 2 Pressurize the whole tower, add 500ml of C4 fraction from the lower part of the reaction section, heat the tower kettle 6 and gradually adjust the pressure to 1.5MPa, and perform total reflux operation;

[0033] c. After half an hour of total reflux operation until the whole tower is basically stable, set the reflux ratio to 5 and start feeding. When feeding, the ethanol-water mixture is fed into the reactive distillation column 6 from the upper end of the reaction section C after being preheated by the metering plunger pump of the storage tank 1. The metering plunger pump is fed into the reactive distillation column 6 from the lower end of the reaction section C after being preheated, and the feed flow rate...

Embodiment 2

[0039] a. first fill the columnar solid acid S-54 resin catalyst filler in the reaction section C of the reactive distillation tower 6, add the ethanol-water mixture feed liquid of 700ml 90wt% in the tower still A;

[0040] b. Then the top of the tower is connected to N 2 Pressurize the whole tower, and add 500ml of C4 fraction, then heat the tower kettle A and gradually adjust the pressure to 2.0MPa, and carry out total reflux operation;

[0041] c. After half an hour of total reflux operation until the whole tower is basically stable, set the reflux ratio to 10 and start feeding. When feeding, the ethanol-water mixture is fed into the reactive distillation column 7 from the upper end of the reaction section C after being preheated by the metering plunger pump of the storage tank 1. The metering plunger pump is fed into the reactive distillation column 6 from the lower end of the reaction section C after being preheated, and the feed flow rate is 263.0ml / h;

[0042] d. with...

Embodiment 3

[0046] a. with step a of embodiment 2;

[0047] B. with the step b of embodiment 1;

[0048] c. After half an hour of total reflux operation until the whole tower is basically stable, set the reflux ratio to 5 and start feeding. When feeding, the ethanol-water mixture is fed into the reactive distillation column 6 from the upper end of the reaction section C after being preheated by the metering plunger pump of the storage tank 1. The metering plunger pump is fed into the reactive distillation column 7 from the lower end of the reaction section C after preheating, and the feed flow rate is 263.0ml / h.

[0049] d. with the step d of embodiment 1;

[0050] e. After the operation of the tower reaches a steady state, the temperature inside the tower kettle A is 130°C, and the temperature at the tower head is 90°C. After continuous operation, the prepared high-performance alcohol-ether mixed fuel is collected in the kettle liquid storage tank 5.

[0051] Analyzed by gas chromatog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com