Temperature-resistant salt-resistant low-tension foam oil-displacing agent as well as preparation method and application thereof

A foam flooding, temperature-resistant and salt-resistant technology, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc. Improve foaming ability and highlight the effect of foam performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

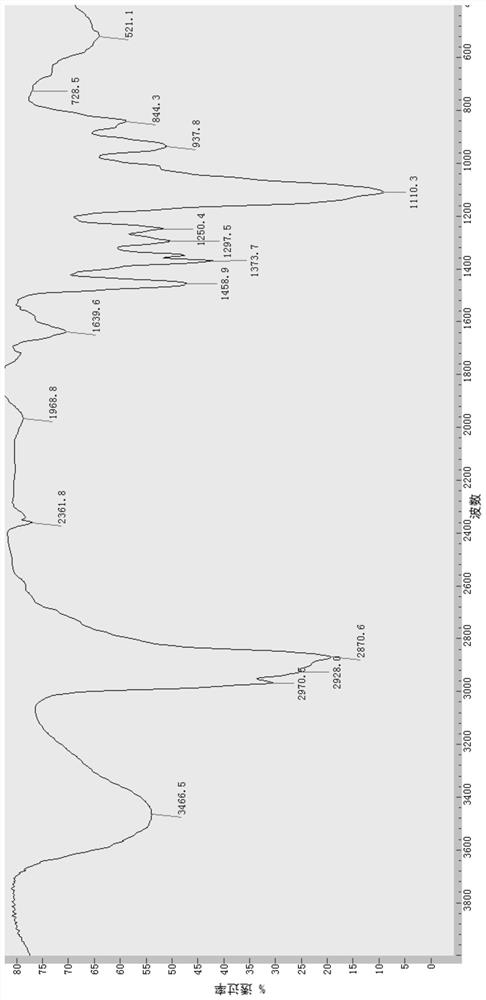

Embodiment 1

[0063] 1) Alkalization reaction of lauryl alcohol polyoxyethylene ether (3):

[0064] Add 318g (1mol) lauryl alcohol polyoxyethylene ether (3) into the reaction kettle with heating, temperature control and electric stirring device, heat up to about 70°C, and use a screw feeder to feed 120g (3.0 mol) solid sodium hydroxide is slowly added to the reaction kettle, after the addition is completed, the temperature is raised to about 75°C, and the reaction is continued for about 2 hours at this temperature;

[0065] 2) carboxymethylation reaction:

[0066] The temperature of the reactant system in the reaction kettle after alkalization in step 1) is lowered to about 55° C., and 141.8 g (1.5 mol) of solid chloroacetic acid is slowly added to the reaction kettle with a screw feeder under constant stirring. After the feeding is completed, Heating to about 80°C, and continuing the constant temperature reaction for about 4 hours to obtain a heat-resistant, salt-resistant, low-tension fo...

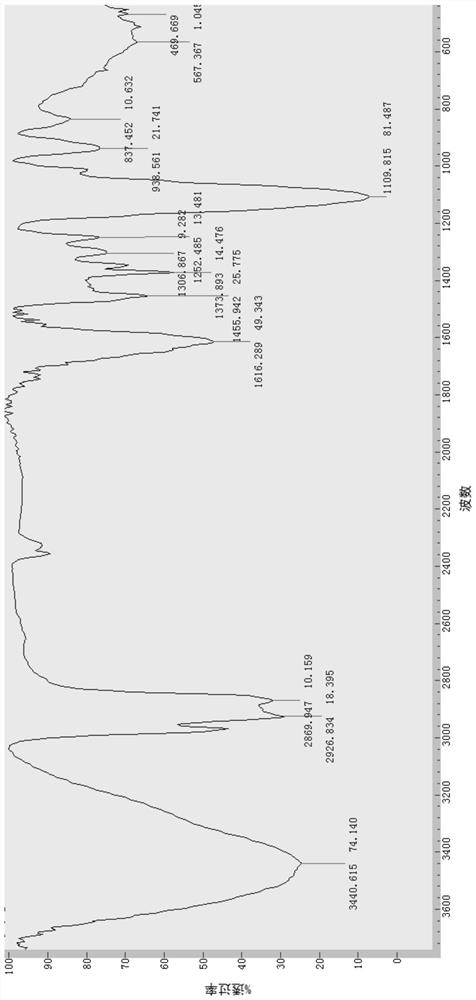

Embodiment 2

[0071] 1) Alkalization reaction of tetradecyl alcohol polyoxyethylene ether (3):

[0072] Add 346g (1mol) tetradecyl alcohol polyoxyethylene ether (3) into the reaction kettle with heating, temperature control and electric stirring device, heat up to about 70°C, and use a screw feeder to feed 112g (2.8 mol) solid sodium hydroxide is slowly added to the reaction kettle, after the feeding is completed, the temperature is raised to about 75°C, and the reaction is continued at this temperature for 1 to 2 hours;

[0073] 2) carboxymethylation reaction:

[0074] The temperature of the reactant system in the reaction kettle after alkalization in step 1) is lowered to about 55°C, and 132.3g (1.4mol) of solid chloroacetic acid is slowly added to the reaction kettle with a screw feeder under constant stirring. After the feeding is completed, Heating to about 85°C, and continuing the constant temperature reaction for 2 to 5 hours to obtain a heat-resistant, salt-resistant, low-tension f...

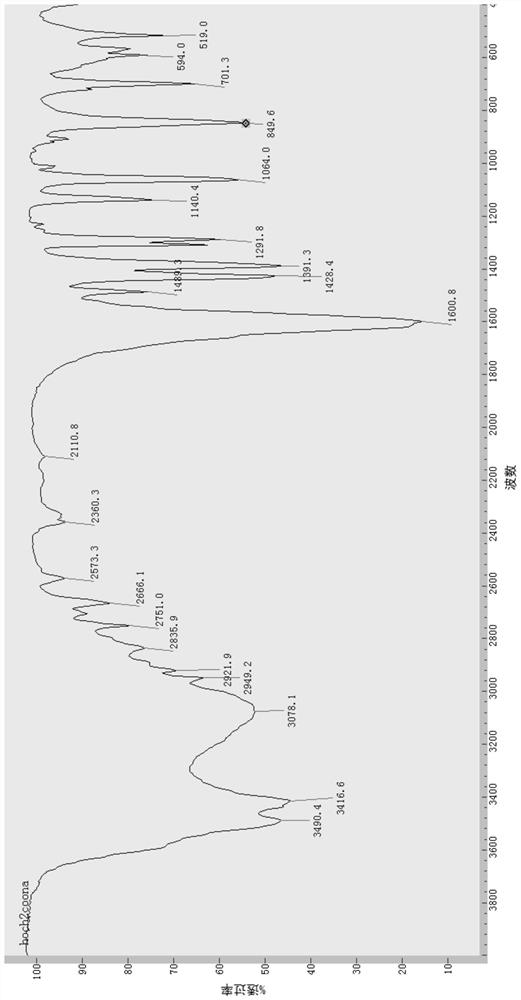

Embodiment 3

[0077] 1) Alkalization reaction of tetradecyl alcohol polyoxyethylene ether (4):

[0078] Add 390g (1mol) tetradecyl alcohol polyoxyethylene ether into the reaction kettle with heating, temperature control and electric stirring device, (4) heat up to about 70°C, and use a screw feeder to feed 112g (2.8 mol) solid sodium hydroxide is slowly added to the reaction kettle, after the feeding is completed, the temperature is raised to about 75°C, and the reaction is continued at this temperature for 1 to 2 hours;

[0079] 2) carboxymethylation reaction:

[0080] The temperature of the reactant system in the reaction kettle after alkalization in step 1) is lowered to about 55°C, and 132.3g (1.4mol) of solid chloroacetic acid is slowly added to the reaction kettle with a screw feeder under constant stirring. After the feeding is completed, Heating to about 85°C, and continuing the constant temperature reaction for 3 to 4 hours to obtain a heat-resistant, salt-resistant, low-tension f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com