SAW filter

A surface acoustic wave and filter technology, applied to electrical components, impedance networks, etc., can solve problems such as lack of flatness of passband characteristics, steep frequency band characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

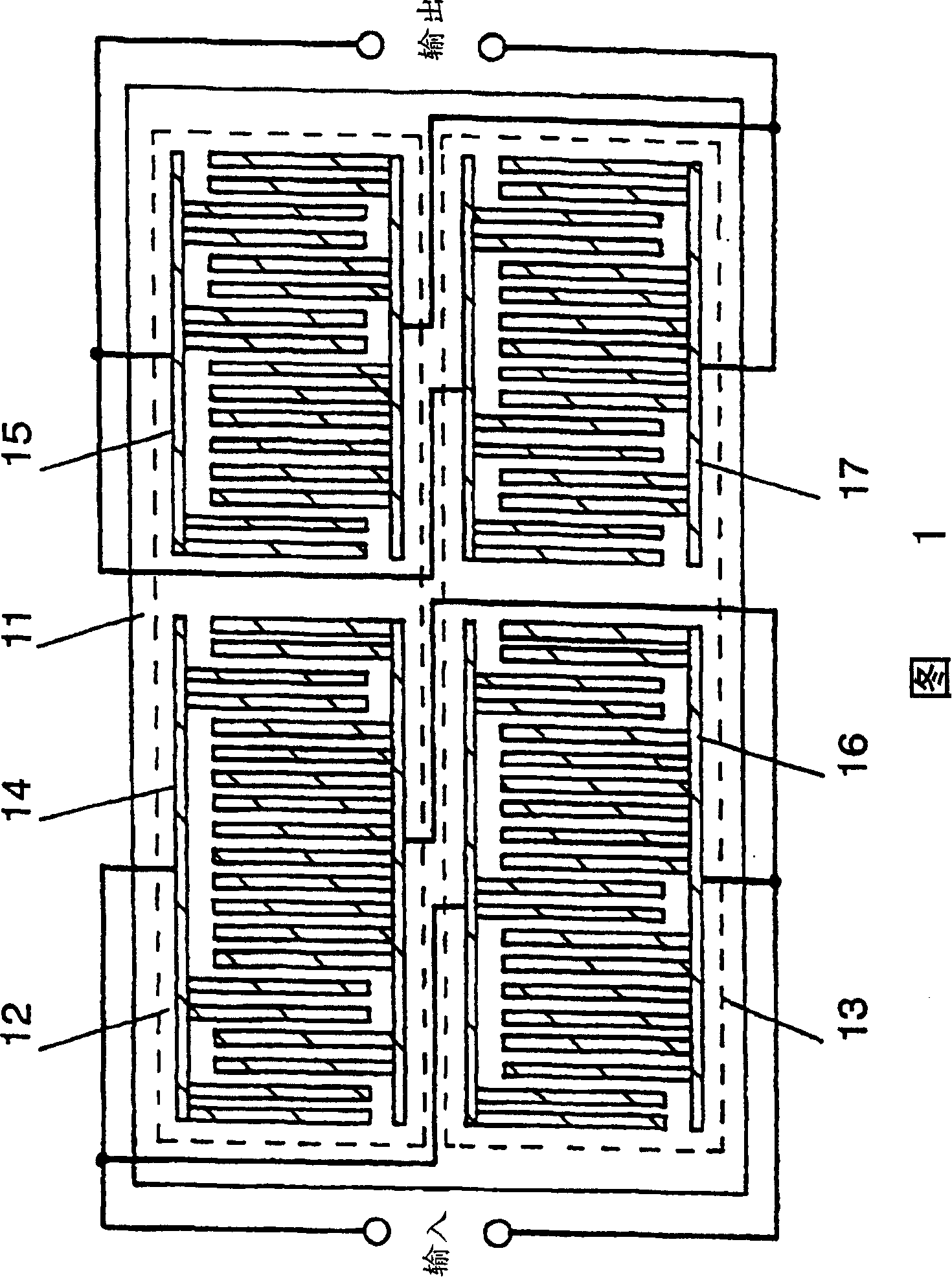

[0018] FIG. 1 is a top view of a SAW filter in Embodiment 1 of the present invention. As shown in FIG. 1 , the first filter track 12 and the second filter track 13 are configured to be connected in parallel on the piezoelectric substrate 11 formed by using a Y-cut crystal substrate rotated at 28° to 42°. The first filter track 12 is formed by an input IDT electrode 14 and an output IDT electrode 15 . Likewise, the second filter track 13 is formed by an input IDT electrode 16 and an output IDT electrode 17 .

[0019] Furthermore, the input IDT electrode 14 of the first filter track 12 and the input IDT electrode 16 of the second filter track 13 are connected in parallel. Likewise, the output IDT electrode 15 of the first filter track 12 and the output IDT electrode 17 of the second filter track 13 are connected in parallel.

[0020] Next, the operation of the SAW filter constructed as described above will be described.

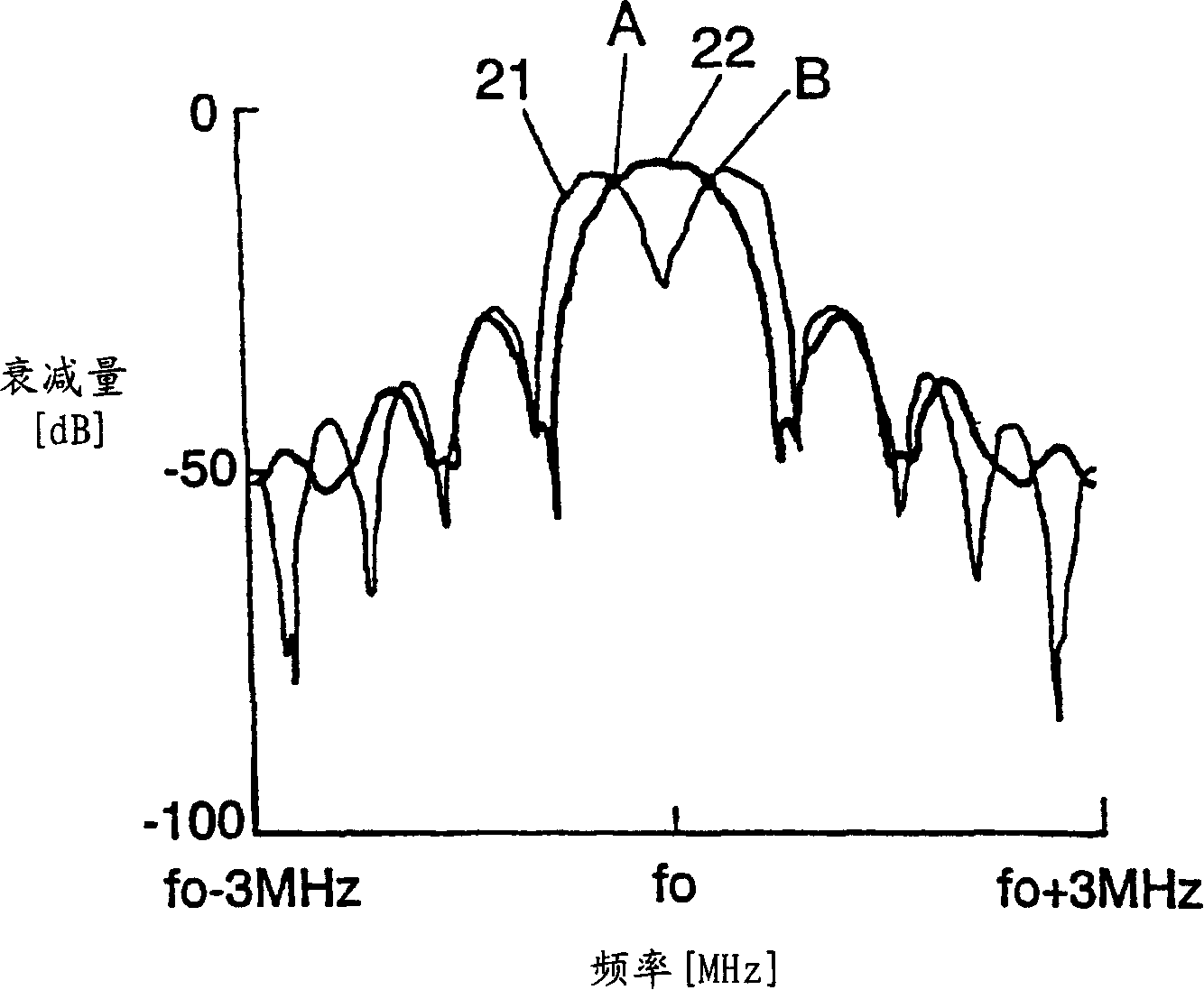

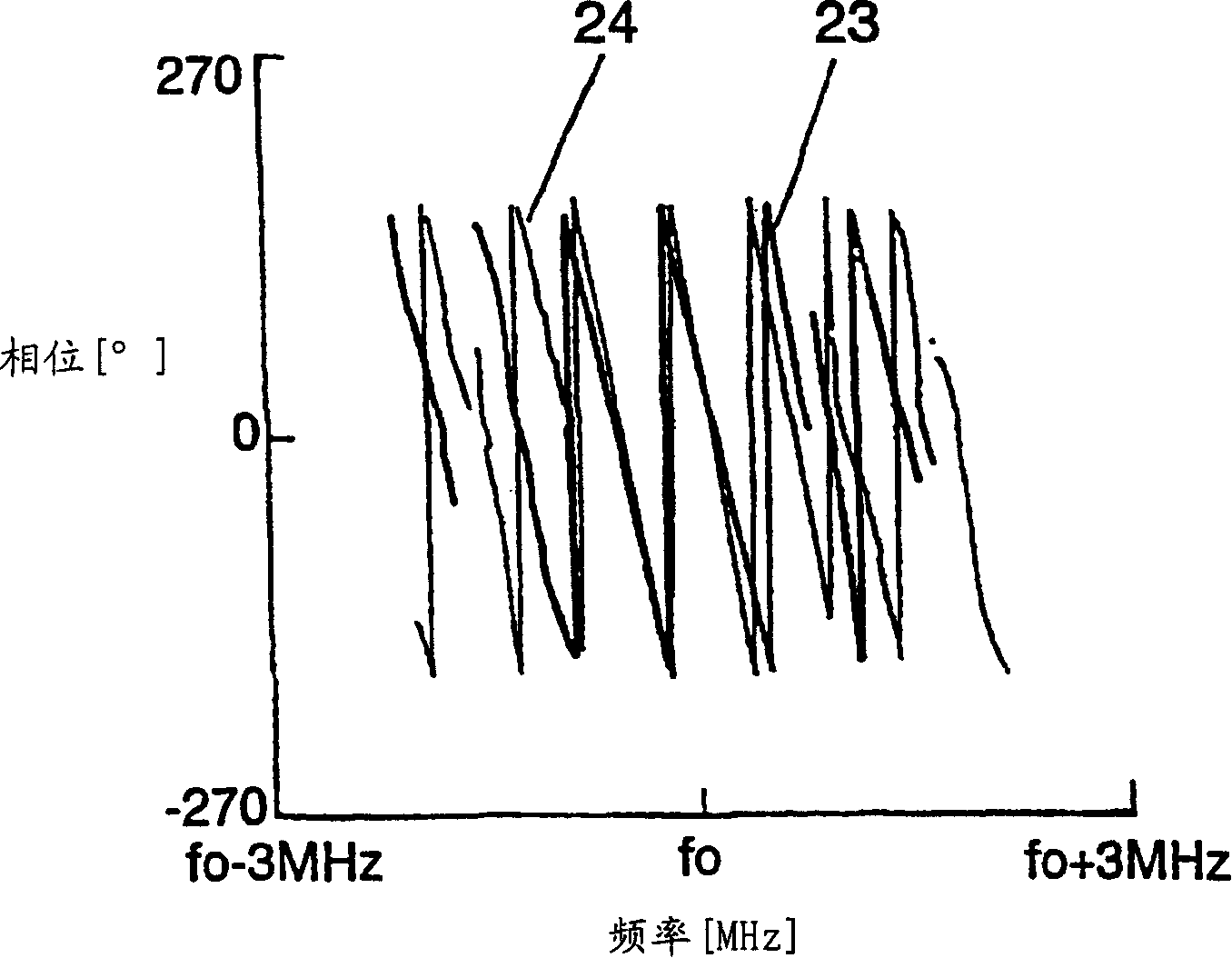

[0021] Figure 2A The amplitude characteristic 21 of t...

Embodiment 2

[0033] Fig. 3 is a plan view of the SAW filter in this embodiment. The SAW filter of this embodiment is the same as that of Embodiment 1, and is a kind of first filter channel 32 and second filter channel 33 with input and output IDT electrodes 34, 35, 36, 37 formed on a piezoelectric substrate 31. SAW filter. Also, the amplitude and phase characteristics of the first and second filter tracks 32, 33 are the same as in the first embodiment.

[0034] The difference from Example 1 is that unidirectional electrodes called EWC-SPUDT (Electrode Width Controlled Single Phase Unidirectional Transducer) are used as electrodes 34 , 35 , 36 , 37 . Specifically, when the electrodes 34, 35, 36, and 37 are divided according to the wavelength λ of the surface acoustic wave, one electrode finger with a width of λ / 4 and two electrode fingers with a width of λ / 8 are provided so that there are three electrode fingers in total. . In FIG. 3, the input IDT electrodes 34, 36 are formed to have ri...

Embodiment 3

[0039] FIG. 4 is a plan view of the SAW filter in Embodiment 3. FIG.

[0040] In this embodiment, the input and output IDT electrodes 44, 45, 46 and 47 that constitute the first filter channel 42 and the second filter channel 43 formed on the piezoelectric substrate 41 are made into electrodes called R-SPUDT (resonant SPUDT) constitute. The electrode structure is the same as that of Embodiment 2, and when the electrodes 44, 45, 46, and 47 are distinguished by the wavelength λ of the surface acoustic wave, there are one electrode finger with a width of λ / 4 and two electrode fingers with a width of λ / 8. Three electrodes refer to the area. Also, the amplitude and phase characteristics of the first and second filter tracks 42, 43 are the same as those of the first embodiment.

[0041] Figure 5 In , the arrows indicate the directivity of the regions A, B, and C framed by dotted lines. Regions A and C impart unidirectionality in the right orientation of the drawing, while regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com