Automatic slice feeder for microscope

A microscope and automatic technology, applied in the direction of microscopes, optics, instruments, etc., can solve the problems of manual replacement, inadaptability, and manned duty of the machine, so as to avoid the deviation of manual operation and speed up the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

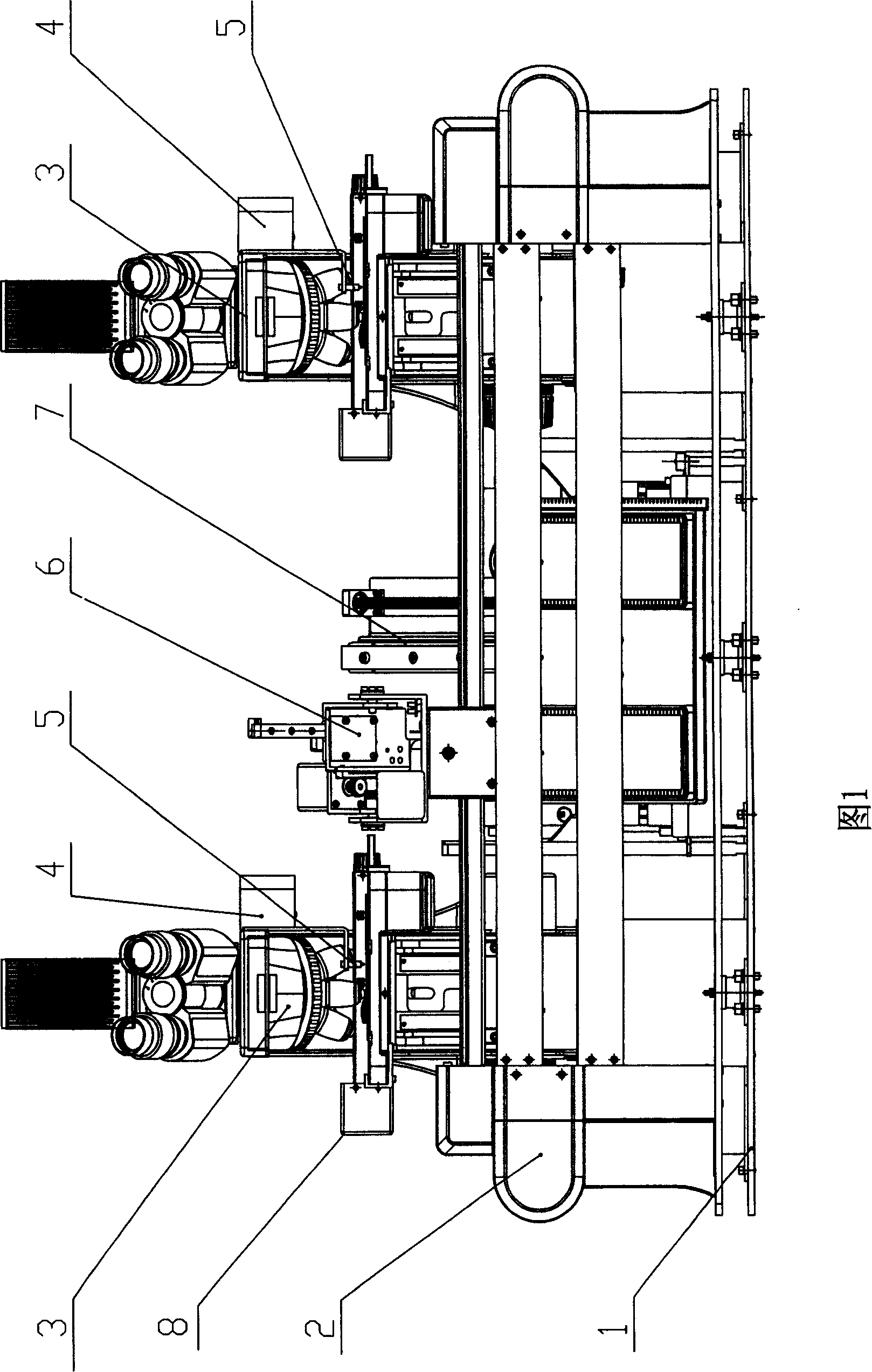

[0044] Embodiment, as shown in Figure 1, the automatic film advance device of microscope comprises: manipulator transfer mechanism 2, automatic microscope 3, bar code reader 4, high-precision switch 5, manipulator 6, slice box bracket 7, stage 8 and body 1. The manipulator 6 is installed on the manipulator transmission mechanism 2 that can move the manipulator 6 along the horizontal X-axis; In this way, the operation of taking and placing slices by the manipulator 6 can be completed in the process of linear movement, while avoiding complex rotary motion. A barcode reader 4 is installed on one side of the microscope 3 , and an object stage 8 and a high-precision switch 5 for detecting the focal plane of the microscope are installed below the microscope 3 .

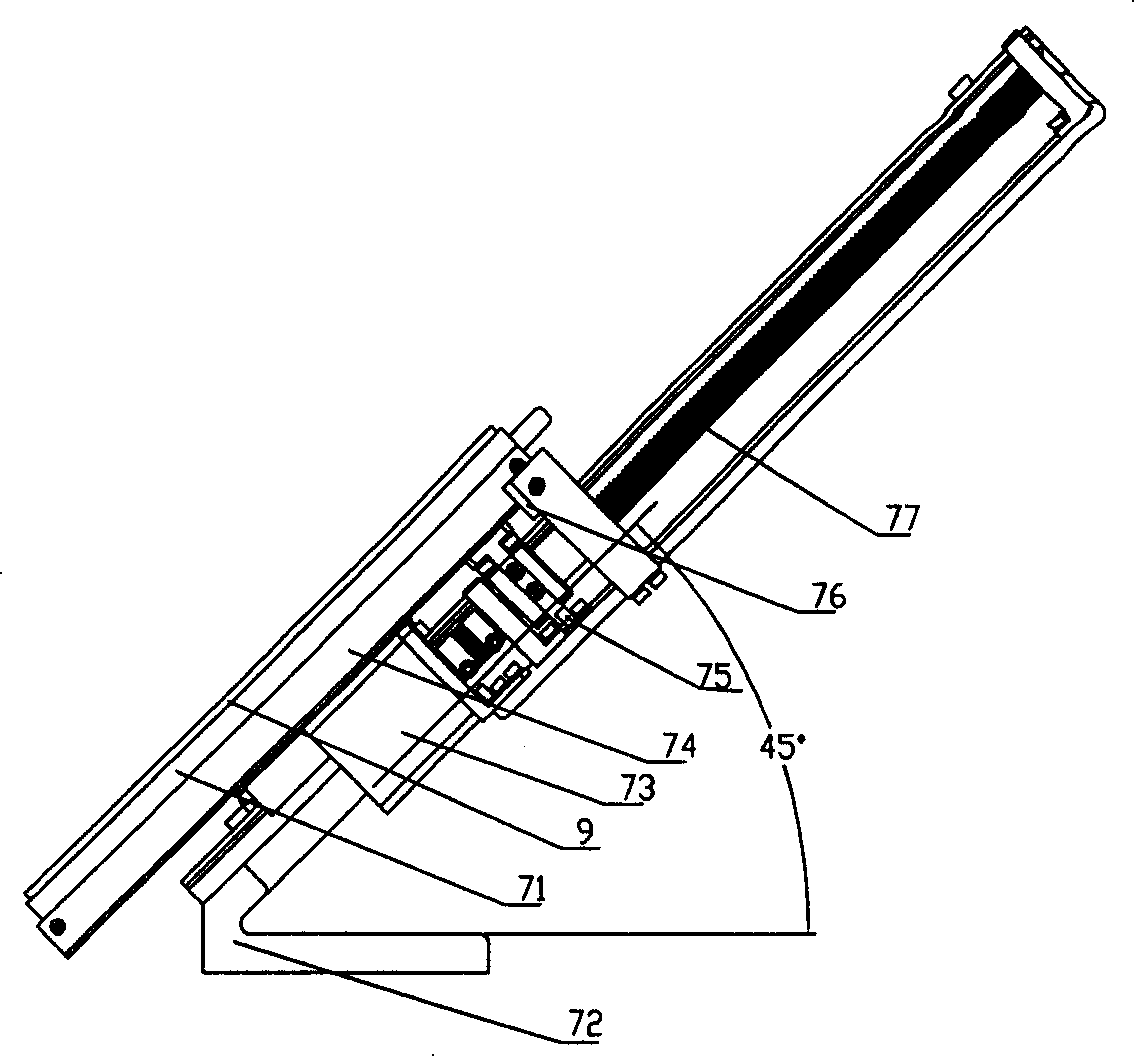

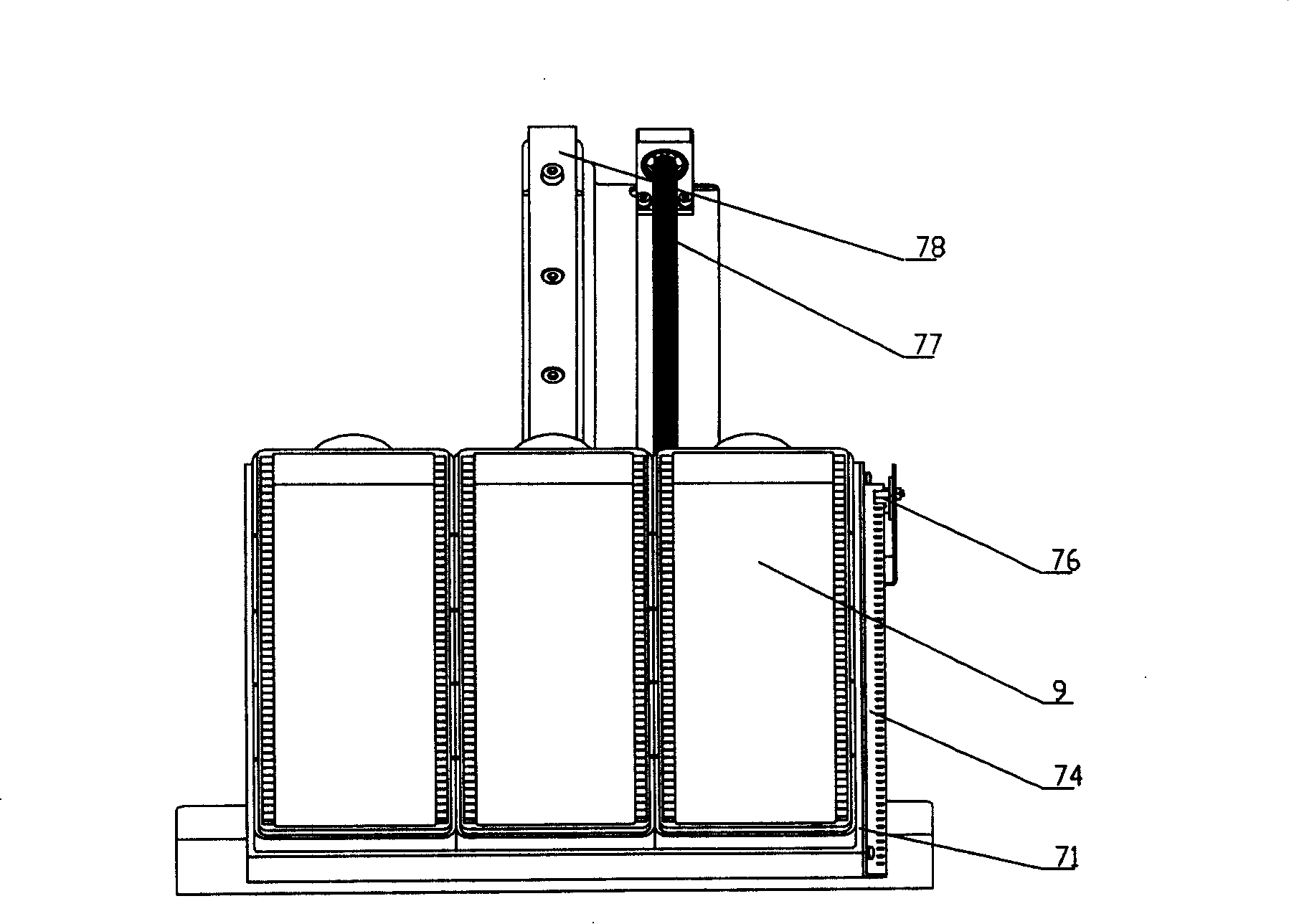

[0045] Slice box holder 7: as attached diagram 2-1 , 2-2 , 2-2, 2-3, 2-4, and 2-5, the slice box bracket 7 includes a fixed body 72 and a movable tray 71, and a lead screw 77 and a linear guide 78 are mounted in parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com