Treatment technology of p-aminotoluene waste water

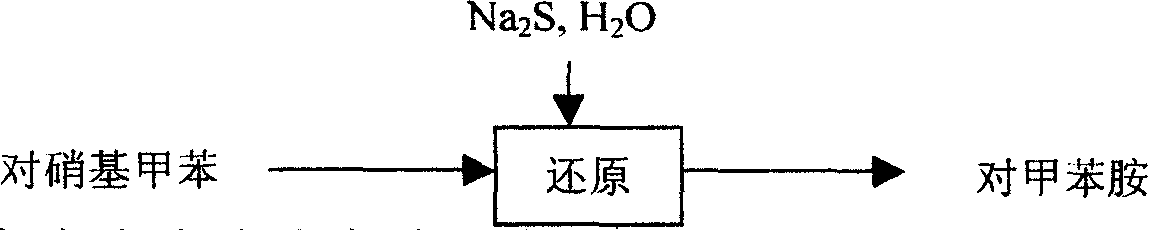

A technology of p-toluidine and p-nitrotoluene, which is applied in water/sewage treatment, reduced water/sewage treatment, water/sewage multi-stage treatment, etc. Issues such as secondary emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

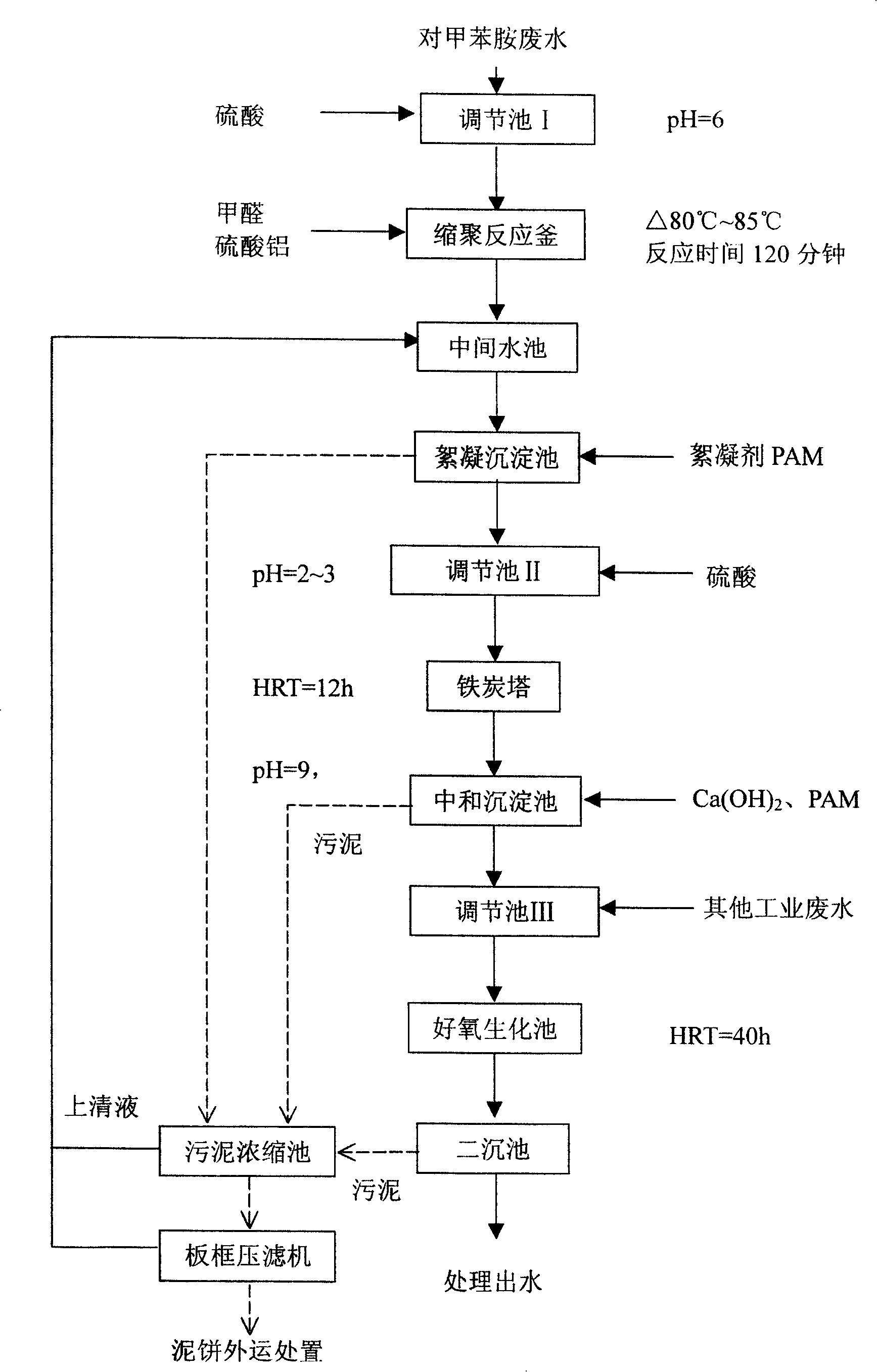

[0019] The present invention relates to a treatment method for p-toluidine waste water, which is to add formaldehyde to the p-toluidine waste water for polycondensation reaction and to form condensate to precipitate out, and then add polymer flocculant polyacrylamide (PAM) for precipitation, thereby The content of aniline compounds in the wastewater is greatly reduced. Then it is treated with the iron-carbon method, and the effluent from the iron-carbon reaction tower is mixed with other industrial wastewater for aerobic biochemical treatment to meet the national secondary discharge standard. Its specific process steps refer to figure 1 :

[0020] Step 1, polycondensation reaction

[0021] The p-toluidine wastewater is collected into the regulating tank I. Add sulfuric acid (concentration ≤ 50%) into the pool to adjust the pH to 6, and stir with air to make the mixture even. The waste water in the regulating tank I is lifted to the enamel reaction kettle with a pump, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com