Automatic lubrication system for shaft of rotating shuttle in many-headed computer embroidery machine

A technology of automatic lubrication and rotary hook, applied in the field of lubrication system, can solve the problems of polluting the product environment, difficult to control the dosage, overflow of lubricating oil, etc., and achieve the effect of prolonging the application life, reducing the wear rate and reducing the disconnection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

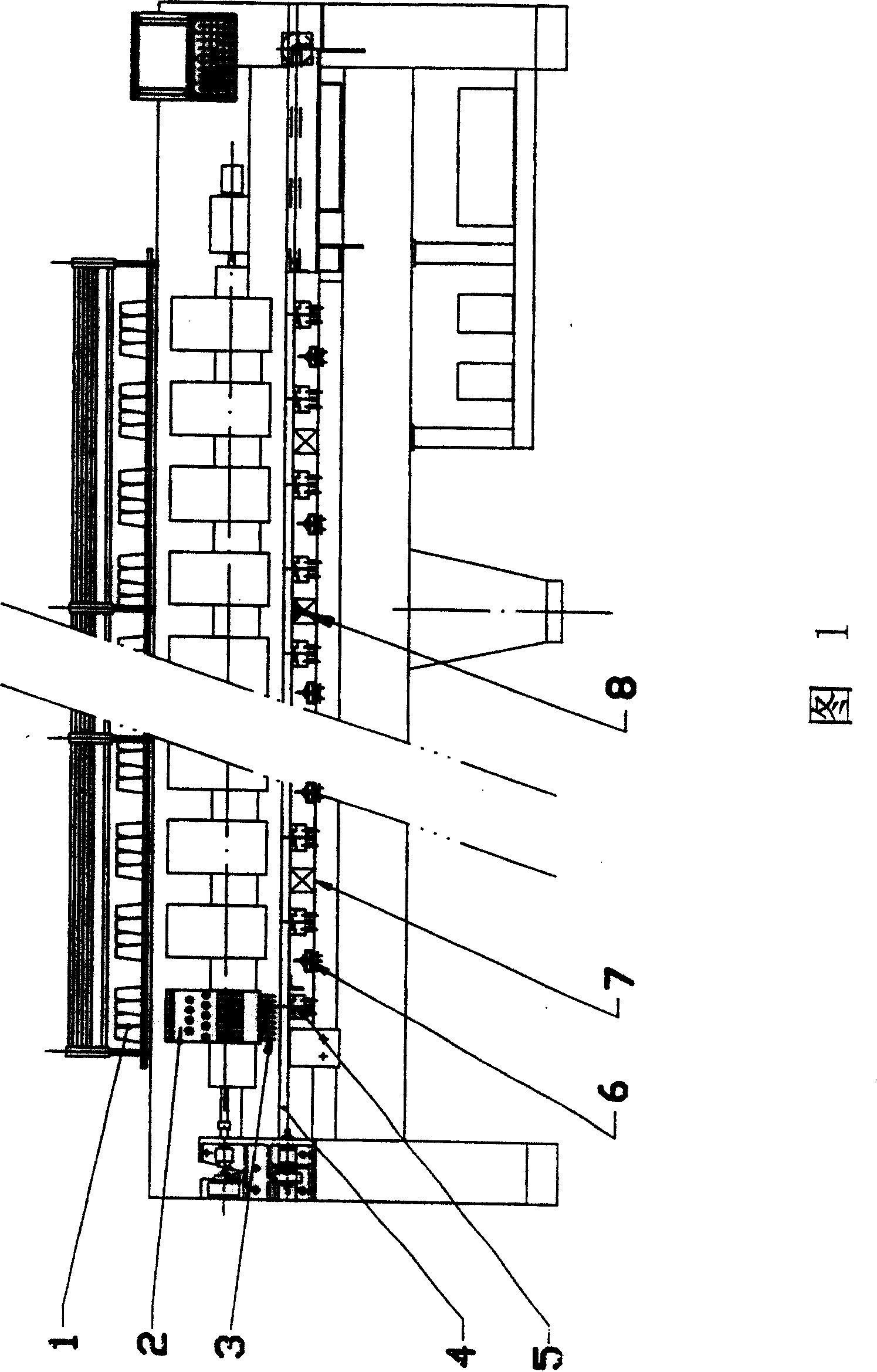

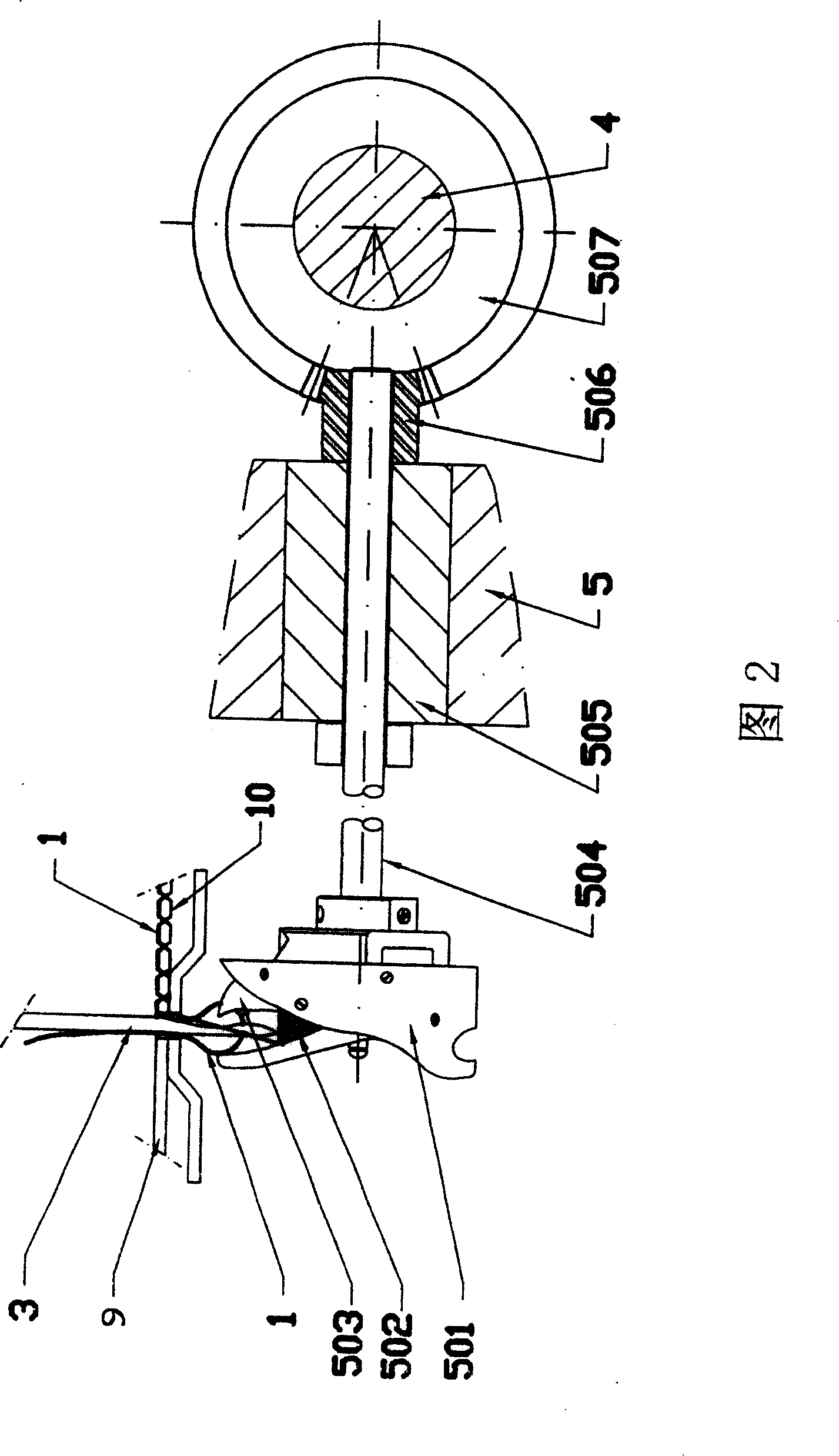

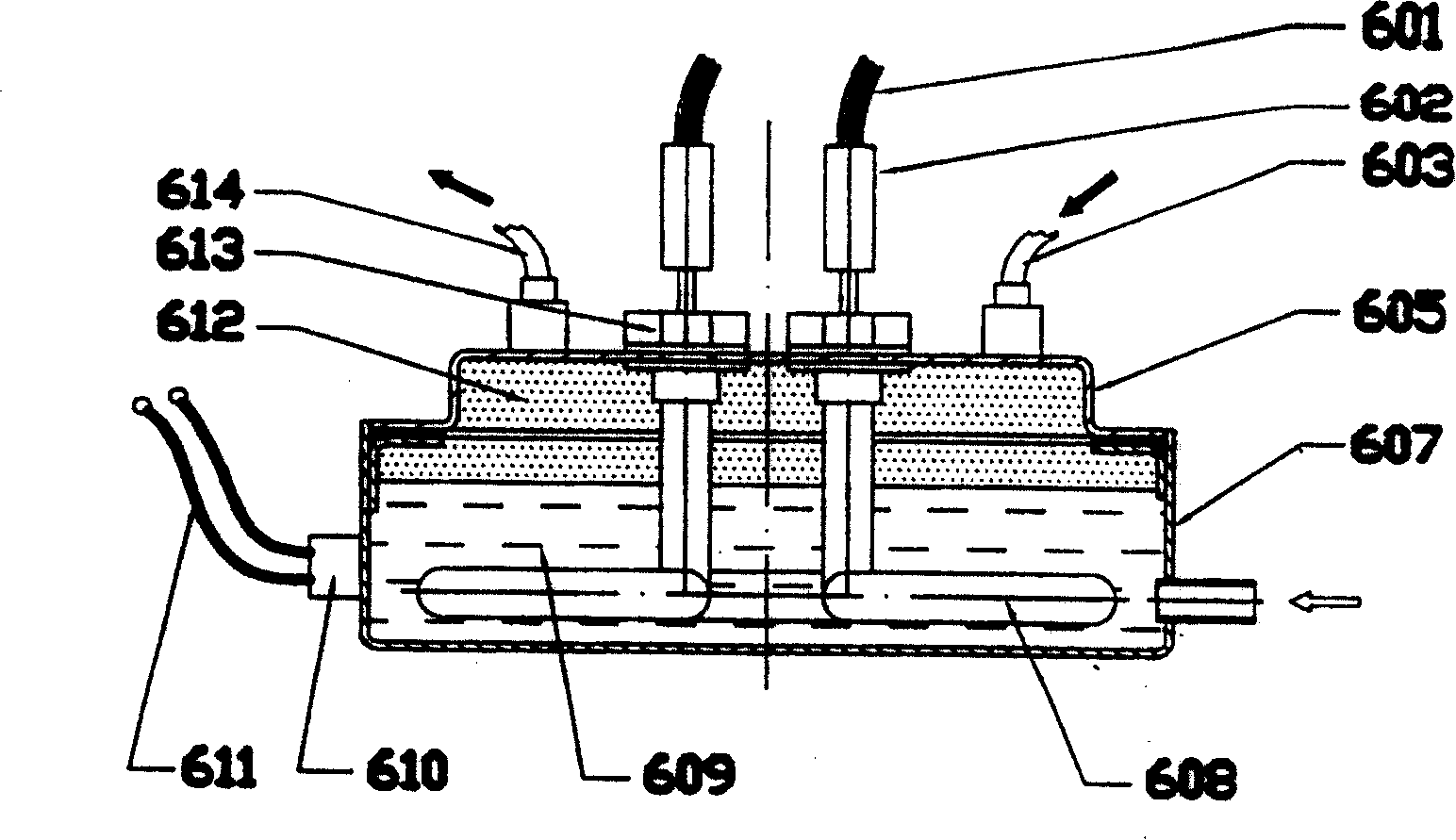

[0018] Since a multi-head computerized embroidery machine has multiple rotary hook shafts, it needs to be equipped with an appropriate amount of heating and atomizing device, that is, there are multiple oil containers, and each oil container can be independent of the rotary hook shafts it is responsible for lubricating. The single-way lubrication device integrates each independent single-way lubrication device to form the circuit of the entire combined lubrication system: a controller 10 sequentially controls the heating wires of multiple oil containers 607, and an air compressor 11 supplies oil to each oil container. The oiler blows air, and an oil tank 804 communicates with each oil container. The oil tank has a liquid level detection device, and an oil pump 12 supplies oil to the oil tank and each machine head 2. The liquid level detection device and the oil pump have control lines to connect with the controller. The controller controls the heating, air blowing and liquid le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com