Method for preparing high stable, reproducible load type photocatalyst of Nano cadmium sulphide

A photocatalyst and a supported technology, which is applied in the field of preparation of a supported nano-cadmium sulfide photocatalyst, can solve the problems of inability to have both activity and stability, damage to the photocatalytic activity of cadmium sulfide, complicated operation steps, and the like, so as to facilitate mass production. , the activity is stable, the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

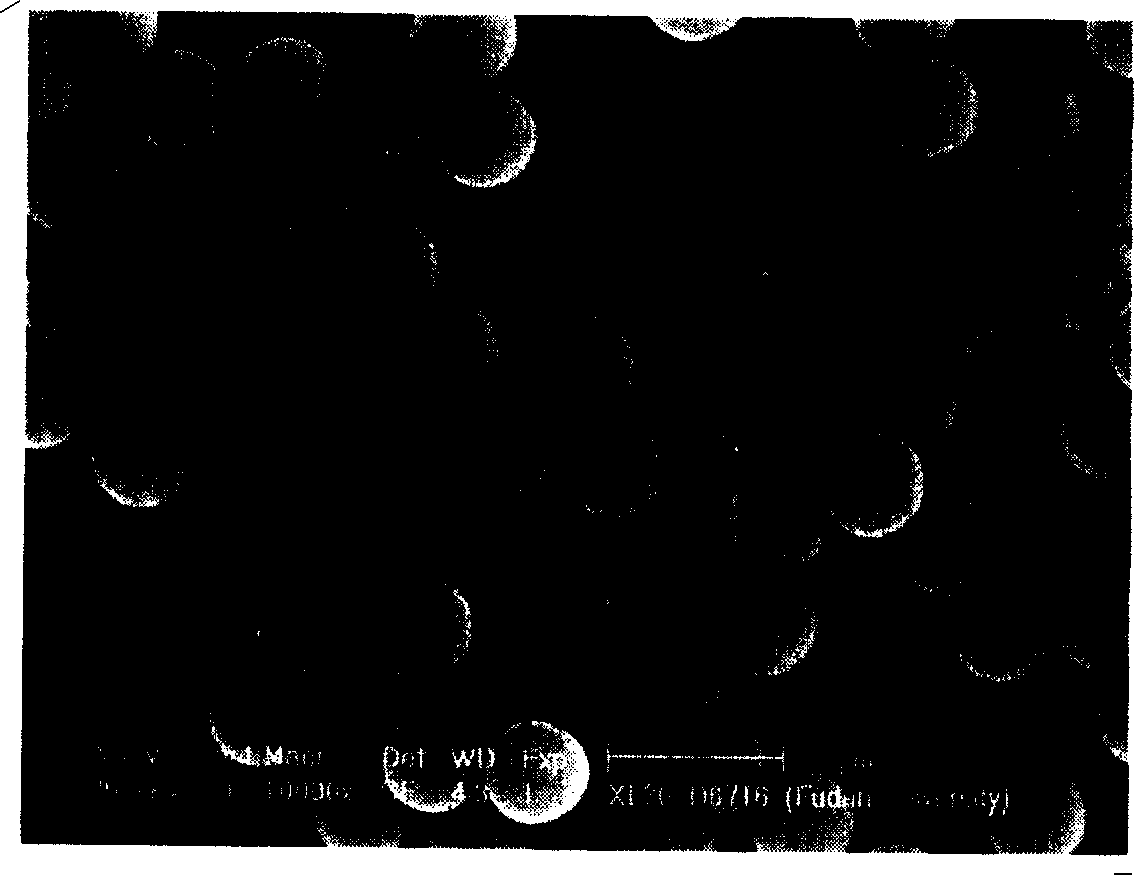

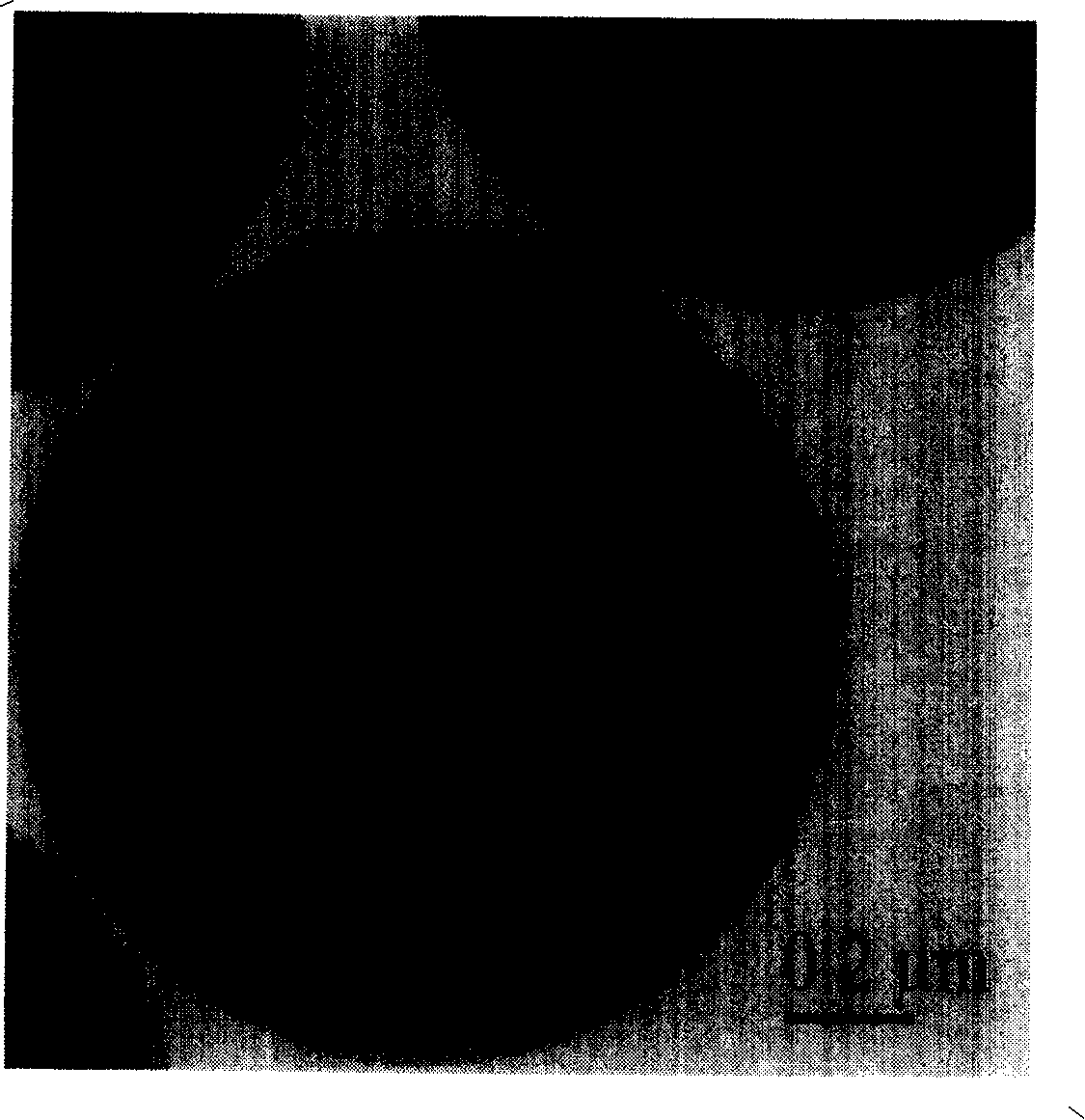

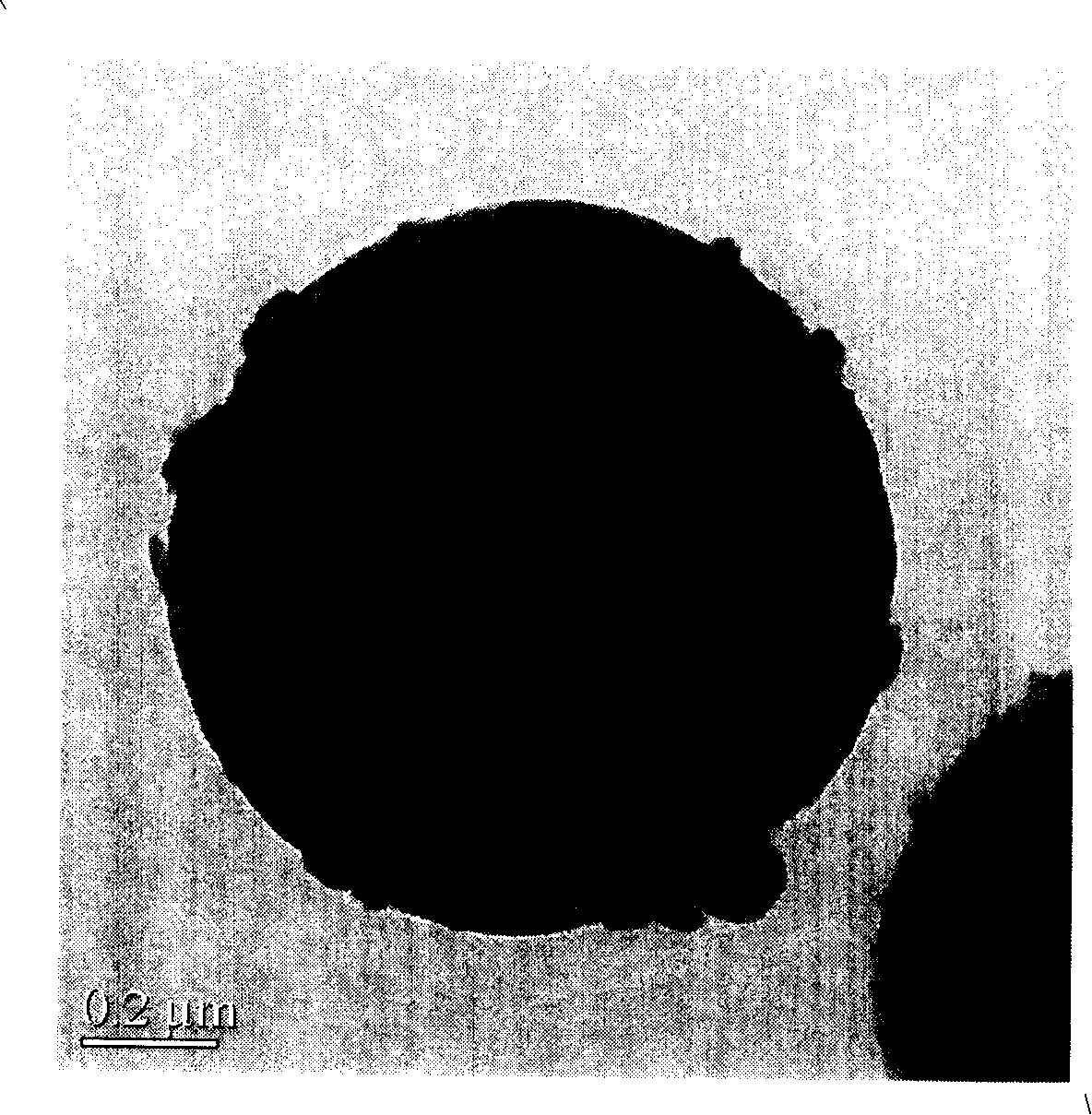

[0042] Mix 1 gram of hexadecylamine, 96.2 milliliters of isopropanol, 86.5 milliliters of distilled water and 1.5 milliliters of ammonia water, stir well at room temperature, then inject 5.8 milliliters of tetraethoxy silicon into the above solution, stop stirring after 30 seconds, and let it stand at room temperature After standing for 1 day, filter, the solid obtained was washed with distilled water, and calcined at 300°C for 6 hours in an air atmosphere to obtain silicon oxide microspheres A 1 .

Embodiment 2

[0044] 1 g of silica microspheres A 1 Disperse in 20 ml of 1 wt% 3-mercaptopropyltriethoxysilane toluene solution, stir at room temperature for 10 hours, wash with toluene, centrifuge, and dry at 80°C to obtain mercapto-modified oxidized Silica Microsphere B 1 .

Embodiment 3

[0046] 1 g of thiol-modified silica microspheres B 1 Disperse in 30 ml of 10wt% cadmium chloride aqueous solution, stir at room temperature for 2 hours, wash and centrifuge, and bake at 300°C for 6 hours under a nitrogen atmosphere to obtain silicon oxide microspheres B with cadmium species immobilized 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com