Half body gear dedicated sling

A spreader and gear technology, which is applied in the field of the special spreader for half-body gears, can solve the problems of large deformation and small furnace loading, and achieve the effects of uniform hardness distribution, easy process manufacturing and improved productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

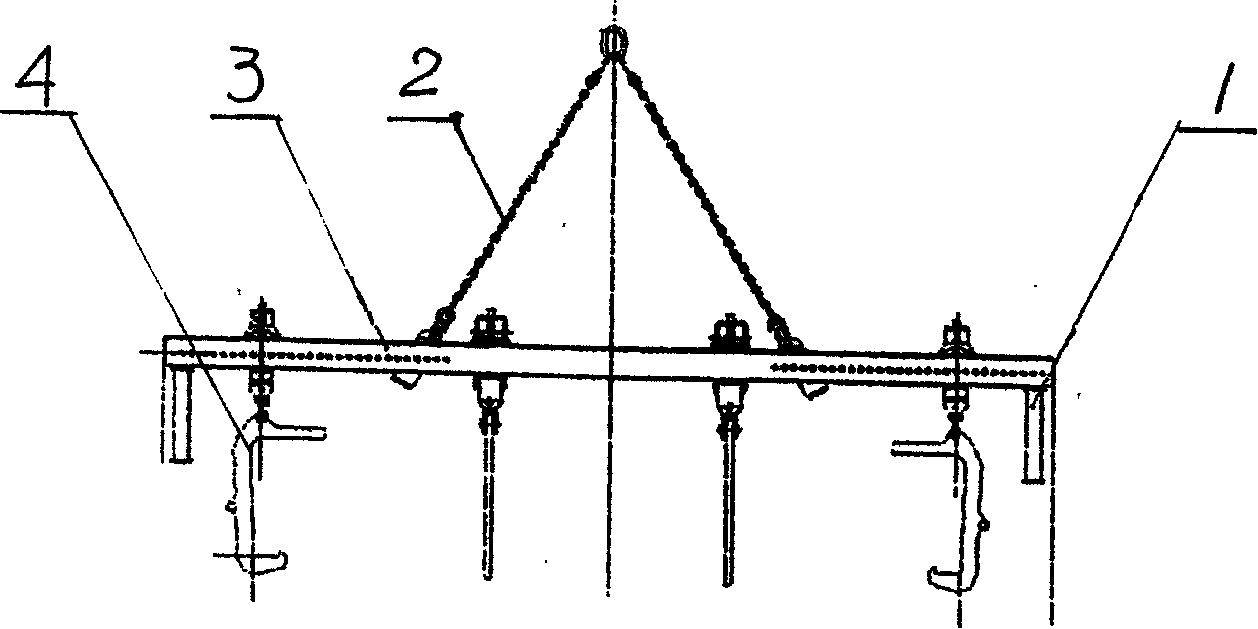

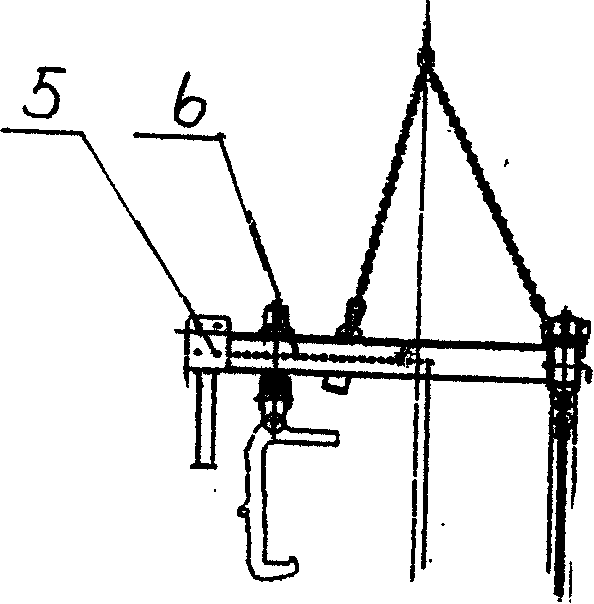

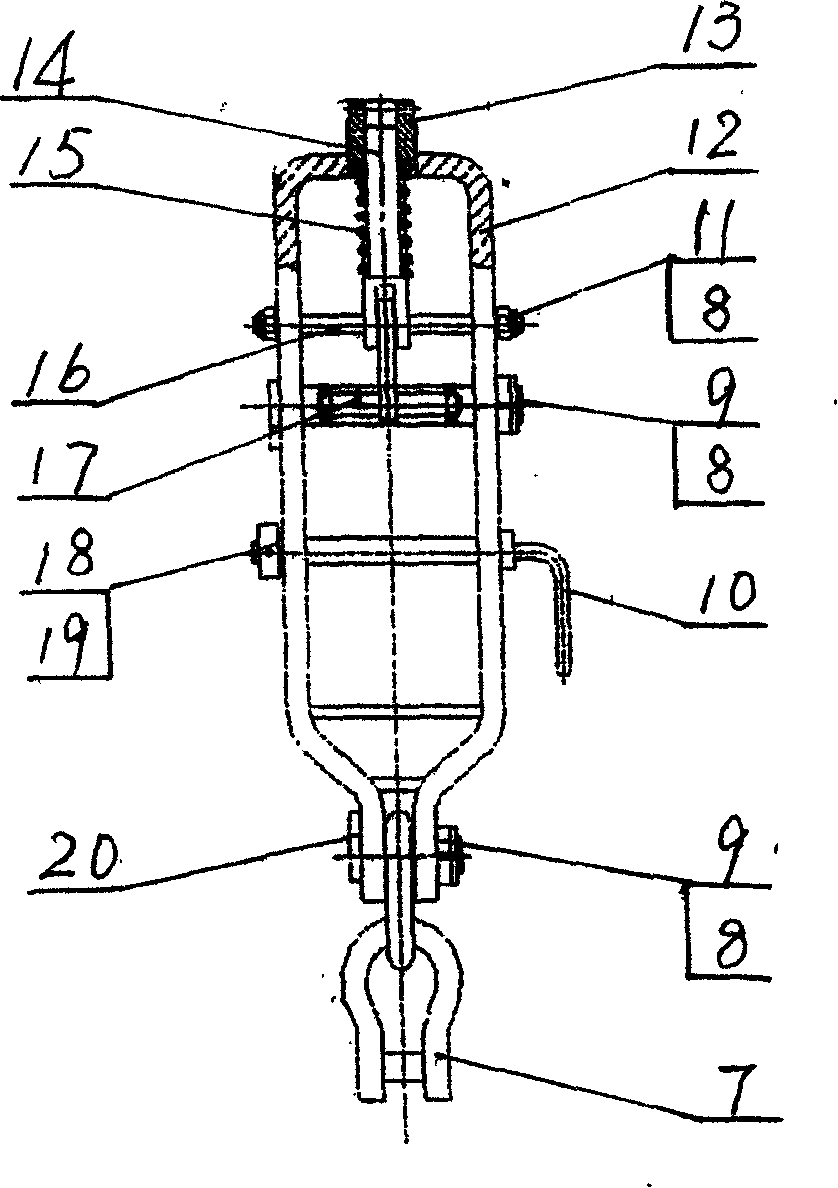

[0015] Embodiment 1, the whole device consists of a bracket 1, a hanging chain 2, a main beam 3, a hook 4, a counterweight 5, an auxiliary beam 6, a hook ring 7, a stopper 8, a round nut 9, an adjustment shaft 10, a nut 11, Regulator body 12, adjusting sleeve 13, adjusting rod 14, compression spring 15, long bolt 16, long shaft 17, slotted nut 18, cotter pin 19, short shaft 20, bearing 21, disc spring 22, hook seat 23 The main beam adjuster is to install the long shaft 17, the round nut 9 and the stopper 8 in the middle and upper part of the adjuster body 12, and install the adjusting rod 14, the bearing 21, the clip spring 15, the adjusting sleeve 13 in the upper part of the adjuster body 12, and use the long Bolt 16, nut 11, retaining piece 8 fasten it, install the adjusting shaft 10 in the middle beam body hole on the regulator body 12, and fasten it with the slotted nut 18, cotter pin 19, and in the regulator body 12 The lower part is equipped with a shackle ring 7, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com