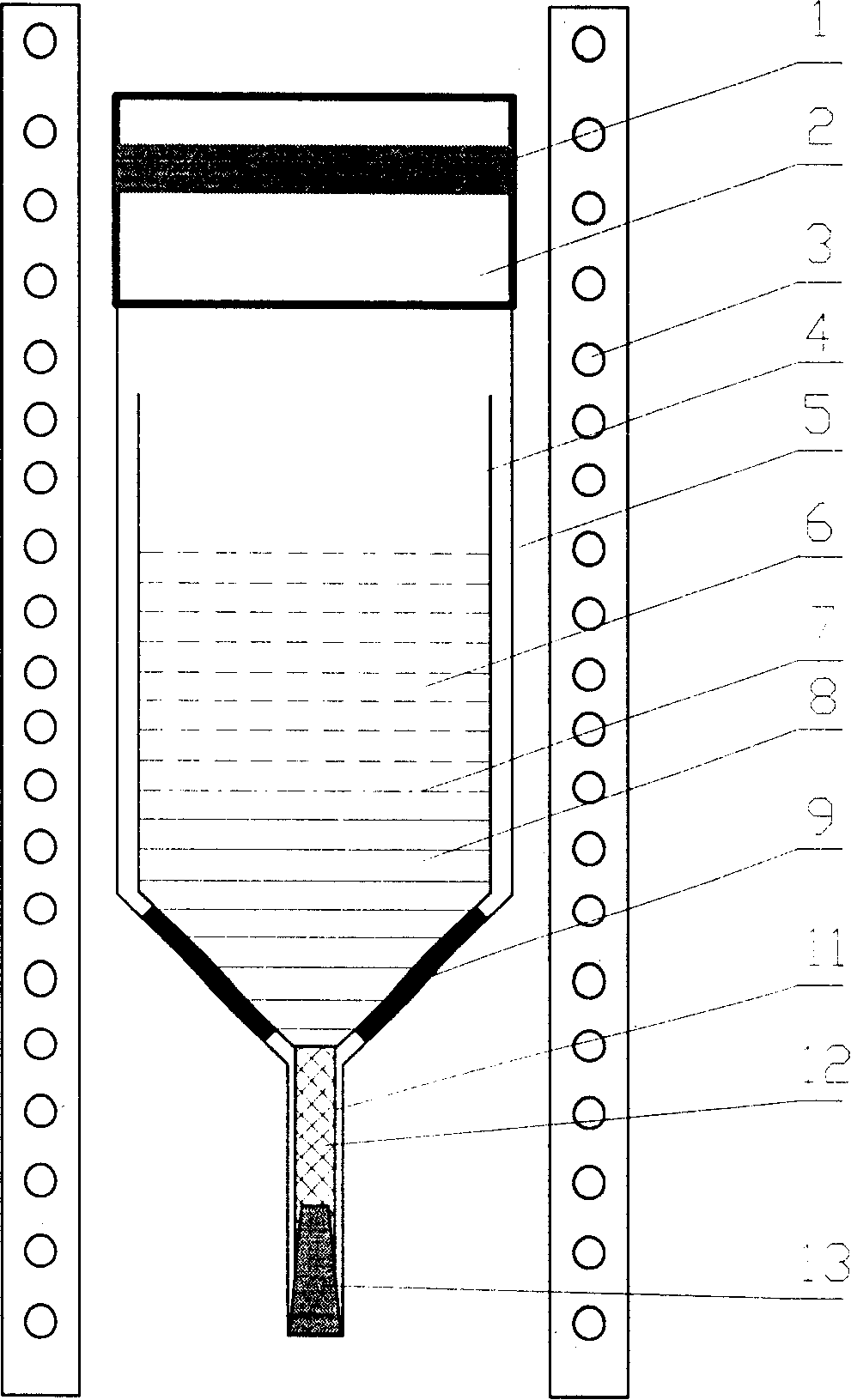

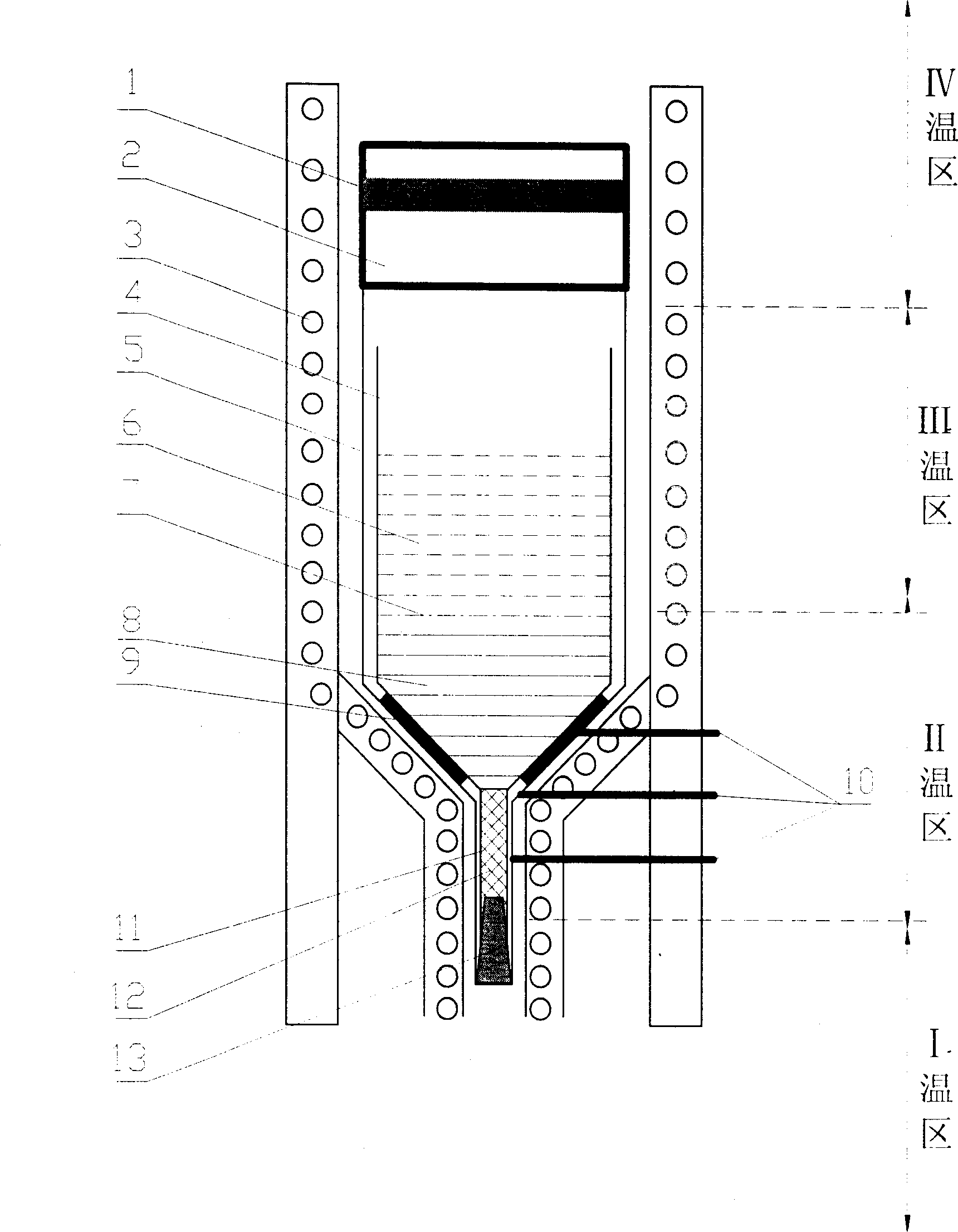

Precise vertical temperature-difference gradient condensation single crystal growth device and method thereof

A gradient condensation and crystal growth technology, applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of crystal growth defects, inability to precisely control temperature changes, large temperature gradient, etc., to achieve crystal quality and yield. The effect of increased rate and more precise control of melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Embodiment 1: Growth of an undoped 4-inch gallium arsenide single crystal

[0019] Add 5.5 kg of gallium arsenide polycrystalline raw materials, control temperature zone I at 1220°C, temperature zone II at 1225°C, and temperature zone III and IV at 1260°C. The crystal growth period (heating, melting, growth, annealing treatment, etc.) is five days. Check the crystal after taking out the single crystal, the length is 100mm, and there is no visible crystal defect; the EDP value after KOH corrosion for 5 minutes at 400°C is 2000 / cm 2 About, compared with the crystal EPD of the usual VGF growth method (about 5000 / cm 2 ) is 60% lower. The single crystals are of very good quality.

[0020] Example 2: Iron-doped 4-inch indium phosphide single crystal growth

[0021] Add 4.8 kg of indium phosphide polycrystalline reaction material containing a small amount of high-purity iron, and add a small amount of red phosphorus to protect the reaction atmosphere. The temperature zone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com