Method for remeasuring semiconductor elements

A semiconductor and component technology, applied in the field of retesting semiconductor components, can solve the problems of limited testing flexibility, chip testing, chip scrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A method for retesting a semiconductor device according to a preferred embodiment of the present invention will be described below with reference to related drawings. The semiconductor device in this embodiment is a chip.

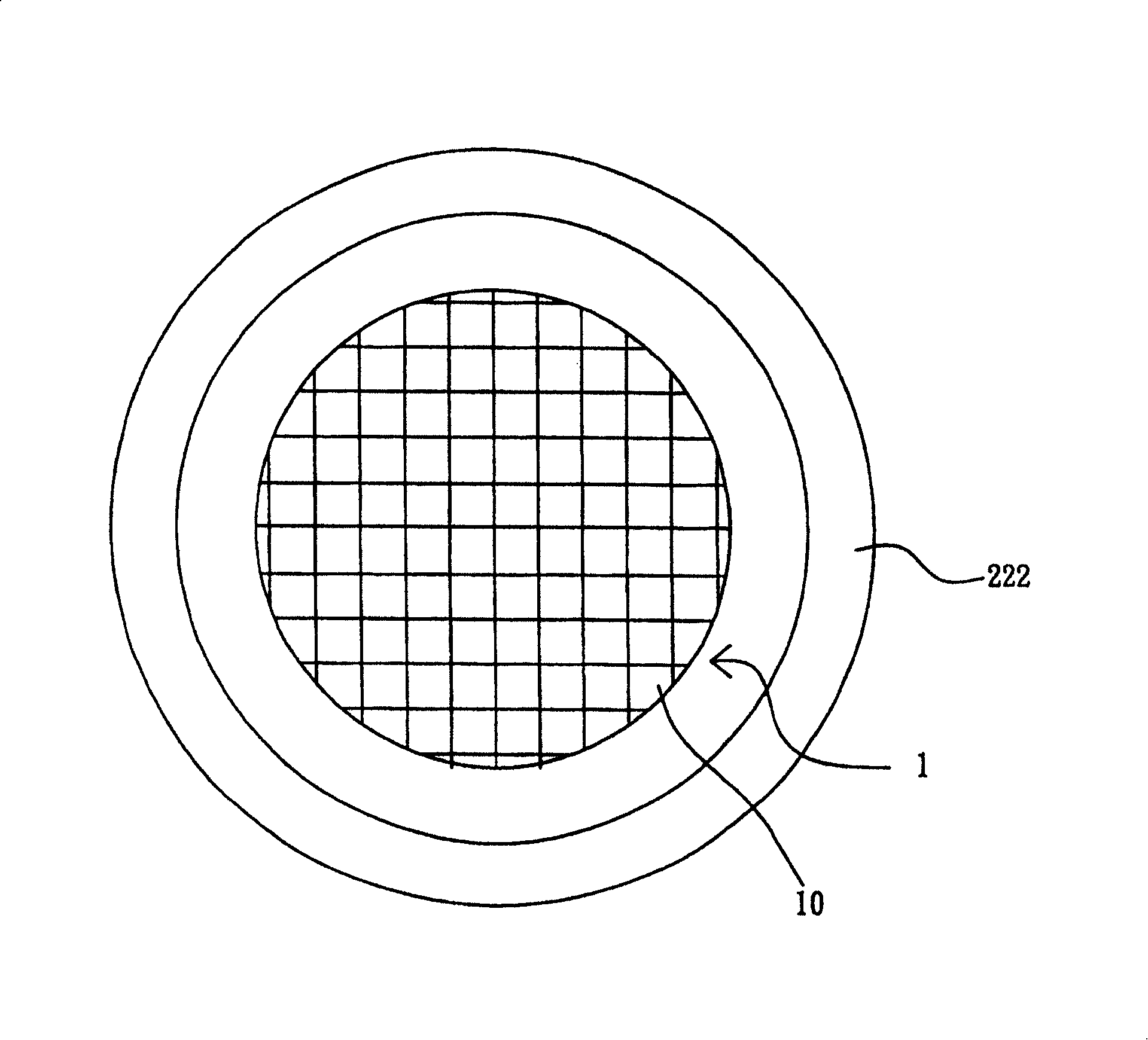

[0024] First, an object under test, such as a wafer, is pasted on a film frame. A wafer contains a plurality of chips, and each chip is independent of signals from each other. Furthermore, a testing machine is provided, and the chips of the wafer are tested for the first time through the testing machine, so as to record the test results. Wherein, the wafer can be cut into a plurality of chips first and then tested, or the wafer can be cut into a plurality of chips after the test is completed.

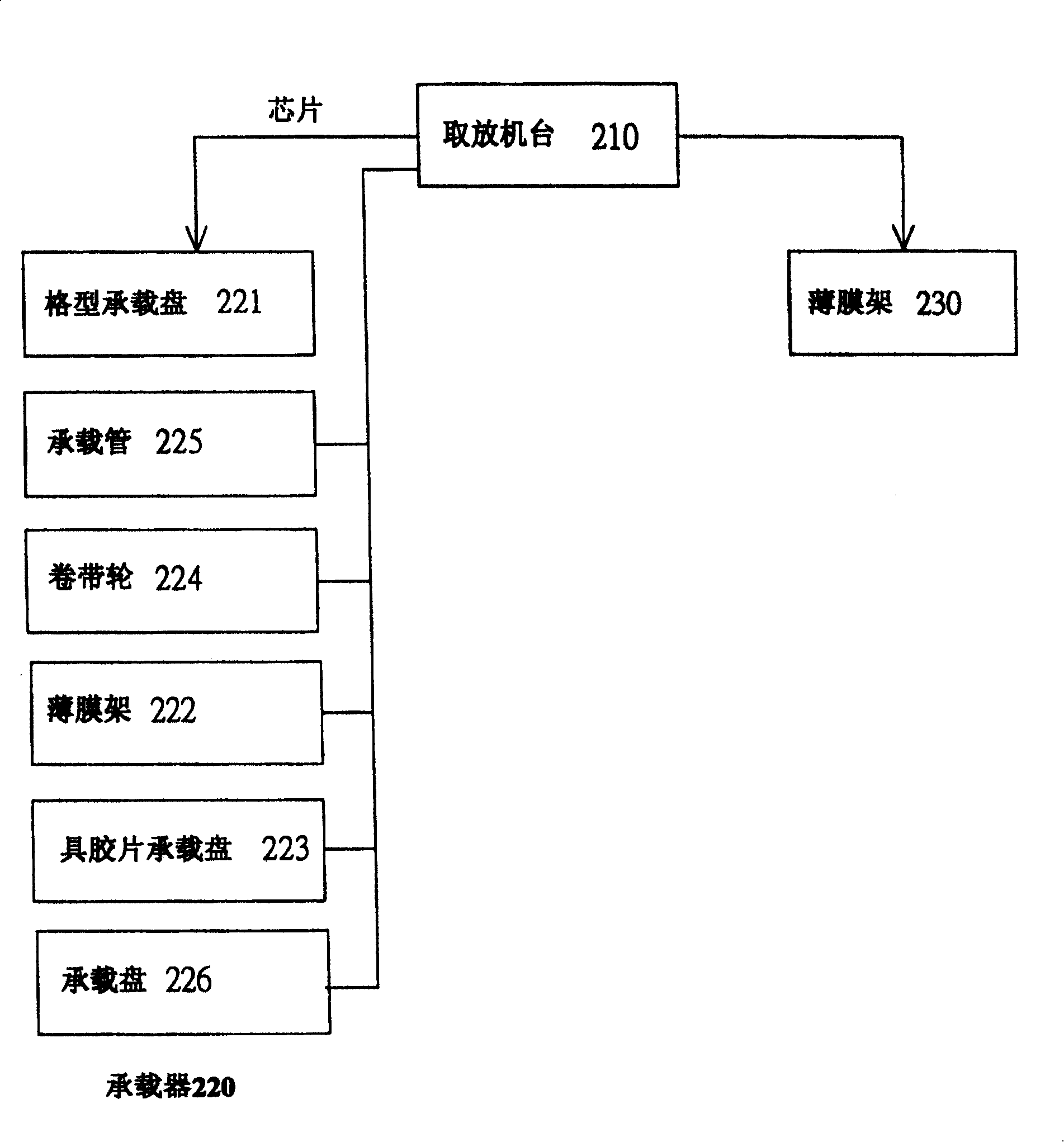

[0025] Then, a pick-and-place machine is provided, and the pick-and-place machine takes out the chips with qualified test results from the film rack in sequence, and respectively accommodates them in a first carrier and a Inside the second carrier. The car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com