Electromagnetic clutch

An electromagnetic clutch and drive shaft technology, applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of shortened response time, variation of torque release time, misalignment of rotation start time, etc., to achieve torque transmission time and torque The effect of shortening the release time, eliminating the deviation of the torque transmission time and torque release time, and improving the responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] [Embodiment 1]

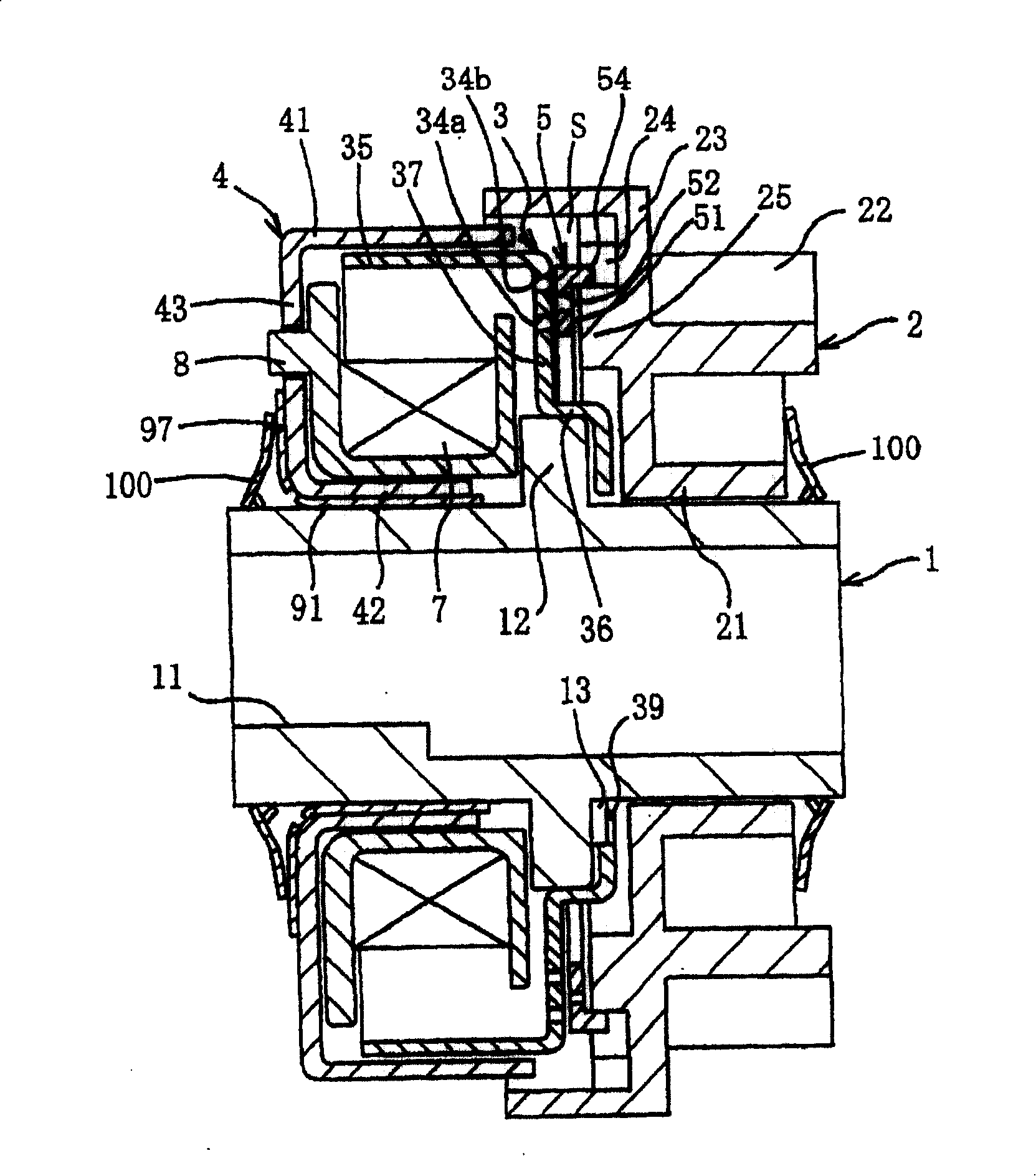

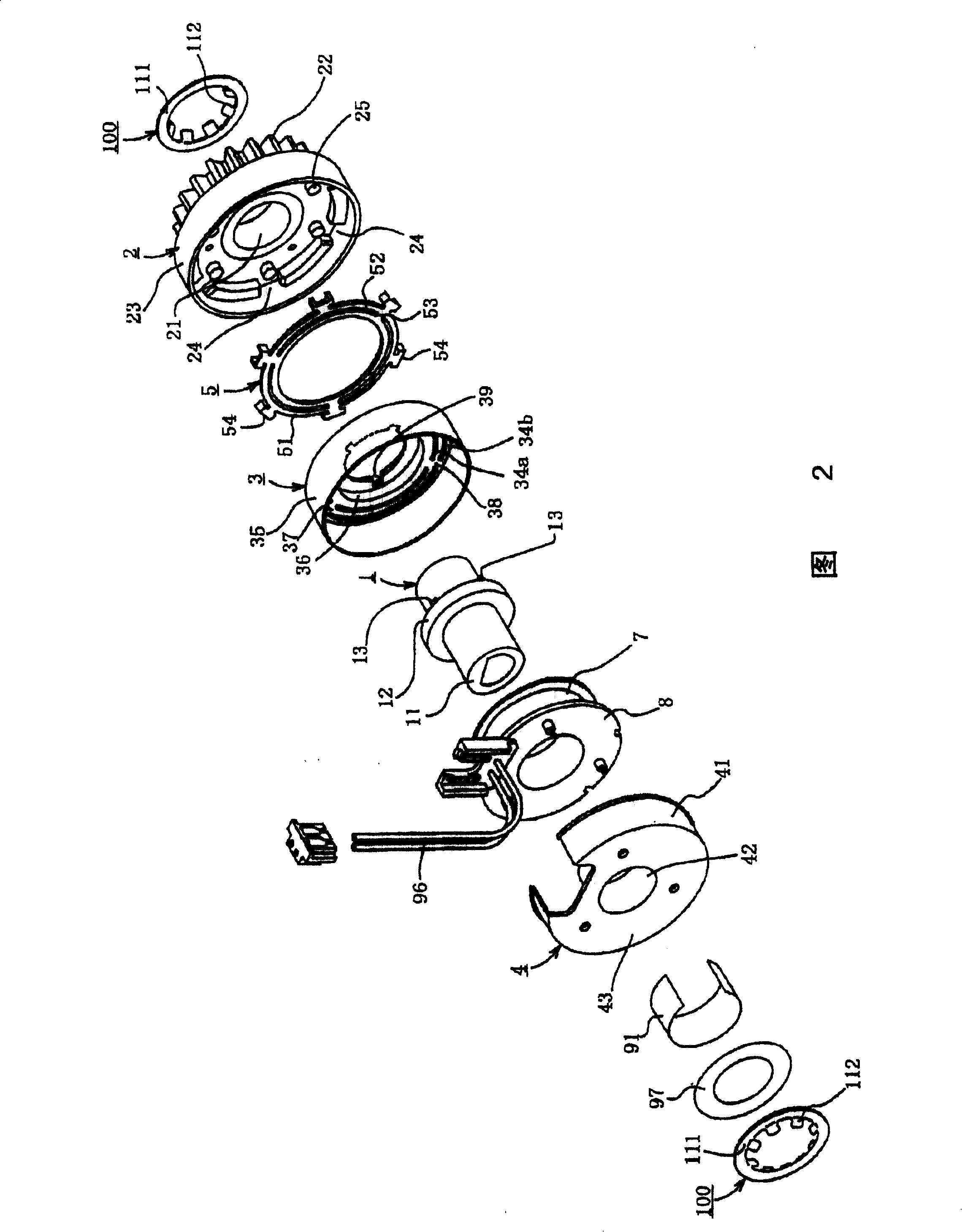

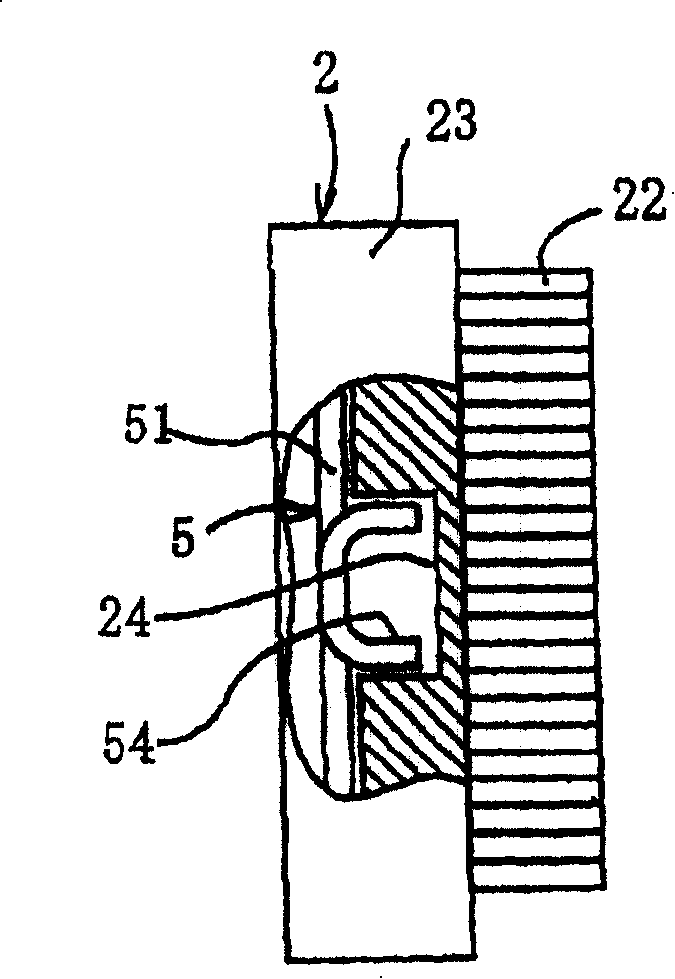

[0032] figure 1 It is a side sectional view showing the electromagnetic clutch according to Embodiment 1 of the present invention, and FIG. 2 is an exploded perspective view showing the same electromagnetic clutch, image 3 It is a partially cutaway side view showing the assembled state of the armature and the rotating body. FIG. 4 shows the shape of the retaining ring. The same figure (a) is its front view, and the same figure (b) is its side view. right with Figure 9 The corresponding components of the shown conventional technology are marked with the same symbols.

[0033] The electromagnetic clutch according to Embodiment 1 is mainly composed of a drive shaft 1, a rotating body 2, a rotor 3, a yoke 4, an armature 5, and a coil 7, and a conventional return spring is omitted.

[0034] The drive shaft 1 is hollow, and its D-cut portion 11 having a D-shaped cross section is connected to a load not shown (in the case of an image forming apparatus, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com