Photosensitive resin for CTP plate and preparation method thereof

A technology of photosensitive resin and epoxy resin, applied in the field of photosensitive resin and its preparation, can solve the problems of low photosensitivity, solvent resistance and slow curing speed of photosensitive resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Modified polystyrene is made by the following steps:

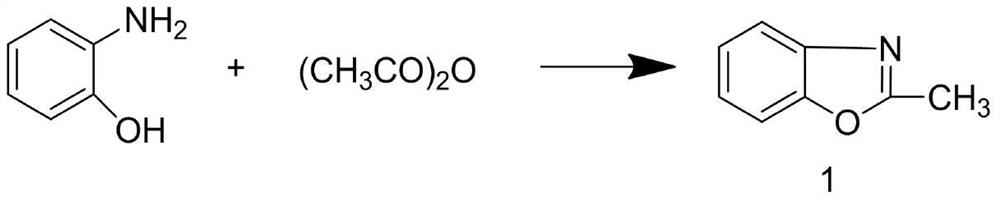

[0047] Step 1. Add 0.25 mol of 2-aminophenol into a round bottom flask, then add 0.8 mol of acetic anhydride, and reflux for 1 hour. After the reaction, distill at 140°C for 5 minutes, then raise the temperature to 195°C, and collect fractions. A light yellow oily liquid intermediate 1 was obtained;

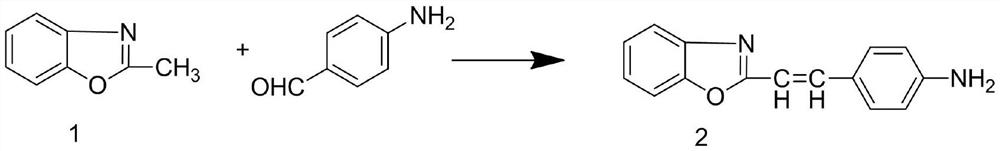

[0048] Step 2. Add 1.2mL of intermediate product 1, 18mL of N,N-dimethylformamide and 3g of potassium hydroxide in turn to the round bottom flask, stir magnetically at room temperature, and at the same time add 1.6mL of 4 -Ethanol solution of aminobenzaldehyde, stirred for 2 hours after the dropwise addition, transferred the reaction product to deionized water after the reaction, and precipitated white flocculent precipitates, left standing for 24 hours, filtered under reduced pressure, and dried to constant weight at 70°C , to obtain the intermediate product 2;

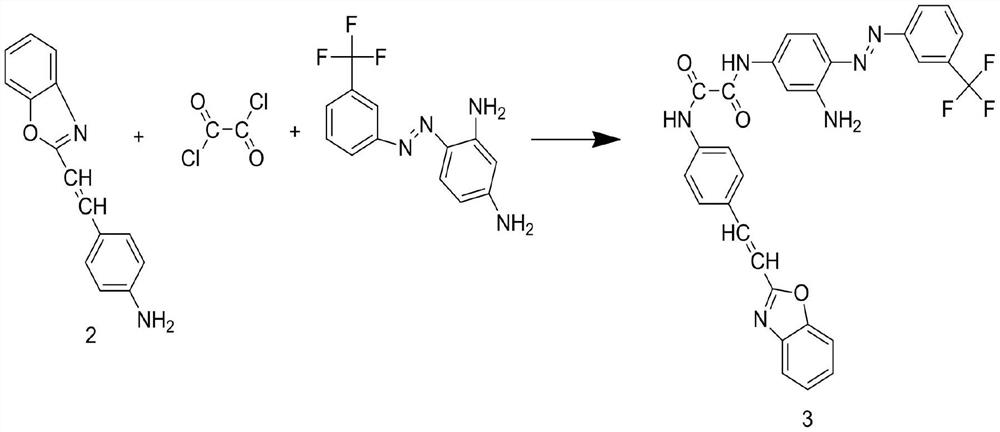

[0049] Step 3. Add 0.03mol of 2,4-diamino-3-trifluoro...

Embodiment 2

[0055] Modified polystyrene is made by the following steps:

[0056] Step 1. Add 0.26 mol of 2-aminophenol into a round bottom flask, then add 0.8 mol of acetic anhydride, and reflux for 1 hour. After the reaction, distill at 140°C for 7 minutes, then raise the temperature to 198°C, and collect fractions. A light yellow oily liquid intermediate 1 was obtained;

[0057] Step 2. Add 1.2mL of intermediate product 1, 19mL of N,N-dimethylformamide and 3g of potassium hydroxide in turn to the round bottom flask, stir magnetically at room temperature, and add 1.6mL of 4 -Ethanol solution of aminobenzaldehyde, stirred and reacted for 2 hours after the dropwise addition, after the reaction, the reaction product was transferred to deionized water, and a white flocculent precipitate was precipitated, left to stand for 24 hours, filtered under reduced pressure, and dried to constant weight at 72°C , to obtain the intermediate product 2;

[0058] Step 3. Add 0.03mol of 2,4-diamino-3-trif...

Embodiment 3

[0064] Modified polystyrene is made by the following steps:

[0065] Step 1. Add 0.27 mol of 2-aminophenol into a round bottom flask, then add 0.8 mol of acetic anhydride, and reflux for 1 hour. After the reaction, distill at 140°C for 8 minutes, then raise the temperature to 205°C, and collect fractions. A light yellow oily liquid intermediate 1 was obtained;

[0066] Step 2. Add 1.2mL of intermediate product 1, 20mL of N,N-dimethylformamide and 3g of potassium hydroxide in turn to the round-bottomed flask, stir magnetically at room temperature, and at the same time add 1.6mL of 4 -The ethanol solution of aminobenzaldehyde, stirred for 2 hours after the dropwise addition, transferred the reaction product to deionized water after the reaction, and precipitated white flocculent precipitate, left it for 24 hours, filtered under reduced pressure, and dried to constant weight at 75°C , to obtain the intermediate product 2;

[0067] Step 3. Add 0.03mol of 2,4-diamino-3-trifluorom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com