Method for preparing quasi-uniform electronic ink micro capsule

An electronic ink and microcapsule technology is applied in the field of preparation of quasi-uniform electronic ink microcapsules, and can solve the problems of difficult control of conditions and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Dissolve the oil-soluble black in tetrachloroethylene, and remove the residue by filtration; weigh 30 mg of surface-modified red powder, use 45 mg of Span80 as a dispersant, and ultrasonically disperse it in 6 mL of tetrachloroethylene containing oil-soluble black.

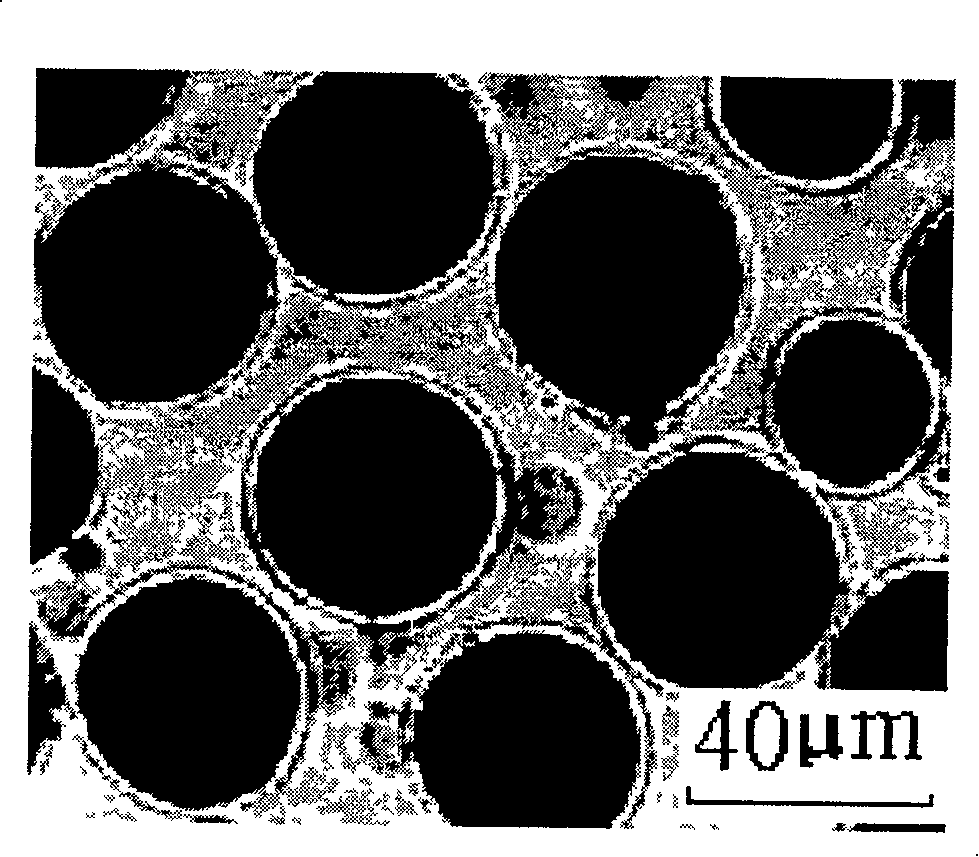

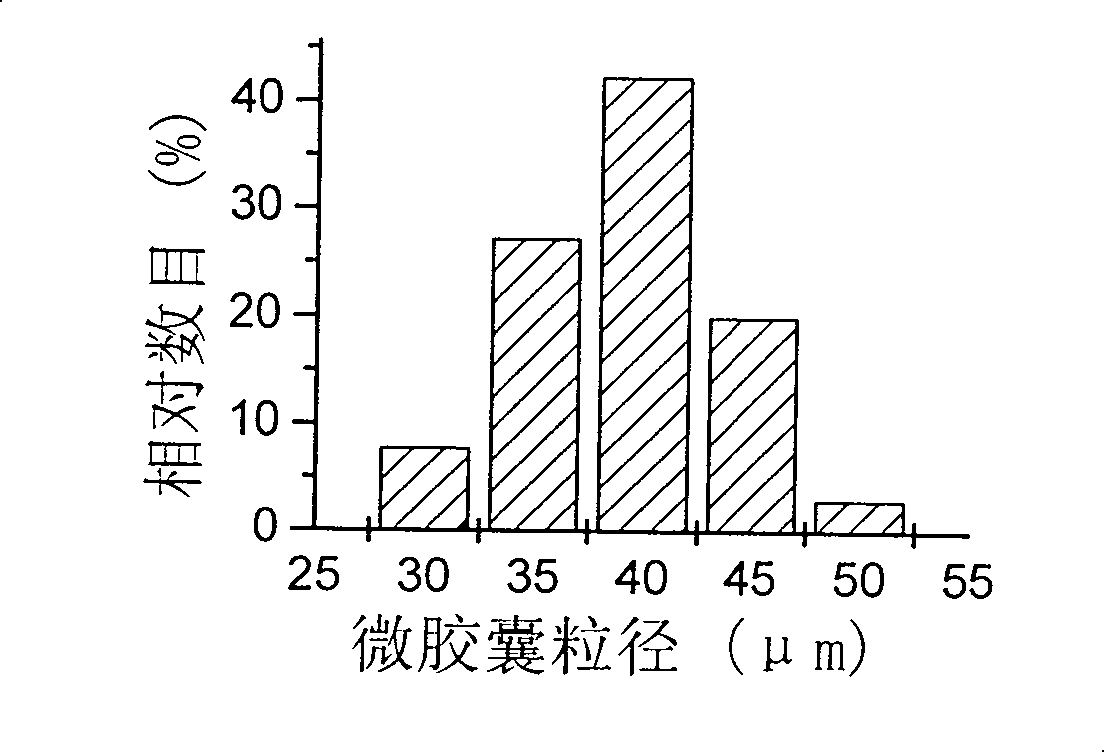

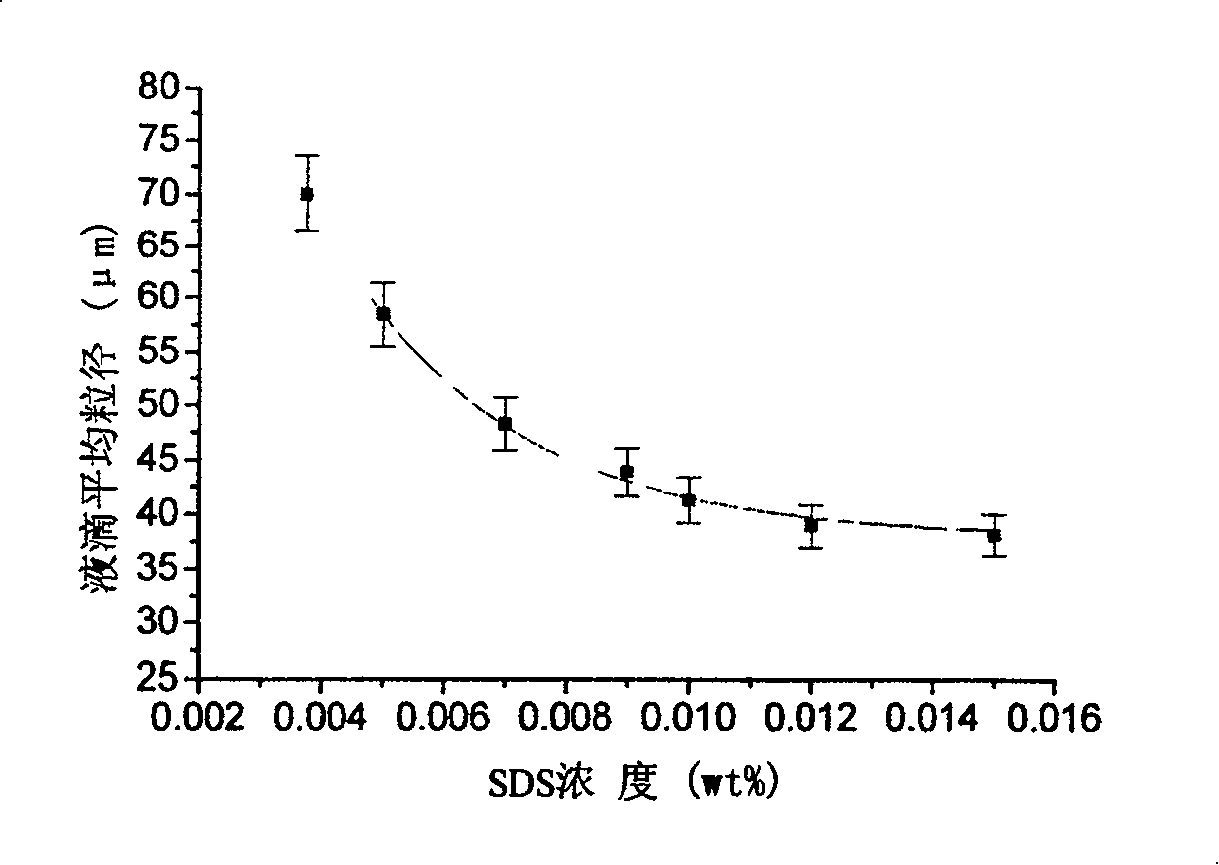

[0015] Dissolve 0.75g of gelatin and 0.75g of gum arabic in 100mL of distilled water respectively, keep at 40-45°C, and mix the two solutions under stirring; at the same time, accurately weigh a certain amount of SDS so that the SDS concentration in the solution is 0.01wt%; add 2mL capsule core, start stirring slowly, control the adjustment time over 15s, make the stirring speed gradually reach 800rpm, keep stirring at 40-45°C for 30min, and obtain quasi-uniformly dispersed electrophoretic base liquid droplets; use 5wt% acetic acid solution, Use more than 5 minutes to slowly adjust the pH of the solution to 3.7, so that the gelatin and gum arabic will re-coagulate. After the coagulated phase is formed, let t...

Embodiment 2

[0017] Dissolve the oil-soluble black in tetrachloroethylene, and remove the residue by filtration; weigh 30 mg of surface-modified red powder, use 45 mg of Span80 as a dispersant, and ultrasonically disperse it in 6 mL of tetrachloroethylene containing oil-soluble black.

[0018] Dissolve 0.75g of gelatin and 0.75g of gum arabic in 100mL of distilled water respectively, keep at 40-45°C, and mix the two solutions under stirring; at the same time, accurately weigh a certain amount of SDS so that the SDS concentration in the solution is 0.005wt%; add 2mL capsule core, start stirring slowly, control the adjustment time over 15s, make the stirring speed gradually reach 800rpm, keep stirring at 40-45°C for 30min, and obtain quasi-uniformly dispersed electrophoretic base liquid droplets; use 5wt% acetic acid solution, Use more than 5 minutes to slowly adjust the pH of the solution to 3.7, so that the gelatin and gum arabic will re-coagulate. After the coagulated phase is formed, let ...

Embodiment 3

[0020] Dissolve the oil-soluble black in tetrachloroethylene, and remove the residue by filtration; weigh 30 mg of surface-modified red powder, use 45 mg of Span80 as a dispersant, and ultrasonically disperse it in 6 mL of tetrachloroethylene containing oil-soluble black.

[0021] Dissolve 0.75g gelatin and 0.75g gum arabic in 100mL distilled water respectively, keep at 40-45°C, and mix the two solutions under stirring; at the same time, accurately weigh a certain amount of SDS so that the SDS concentration in the solution is 0.015wt%; add 2mL capsule core, start stirring slowly, control the adjustment time over 15s, make the stirring speed gradually reach 900rpm, keep stirring at 40-45°C for 30min, and obtain quasi-uniformly dispersed electrophoretic base liquid droplets; use 5wt% acetic acid solution, Use more than 5 minutes to slowly adjust the pH of the solution to 3.7, so that the gelatin and gum arabic will re-coagulate. After the coagulated phase is formed, let the mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com