Method for producing thrust plate and method for producing shaft for hydrodynamic bearing

A technology of dynamic pressure bearing and thrust plate, applied in the direction of shaft and bearing, sliding contact bearing, bearing of rotary motion, etc., can solve the problems of inconsistent inner diameter, single structure, and increased production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] 1. The first embodiment

[0027] (1) The overall structure of the spindle motor

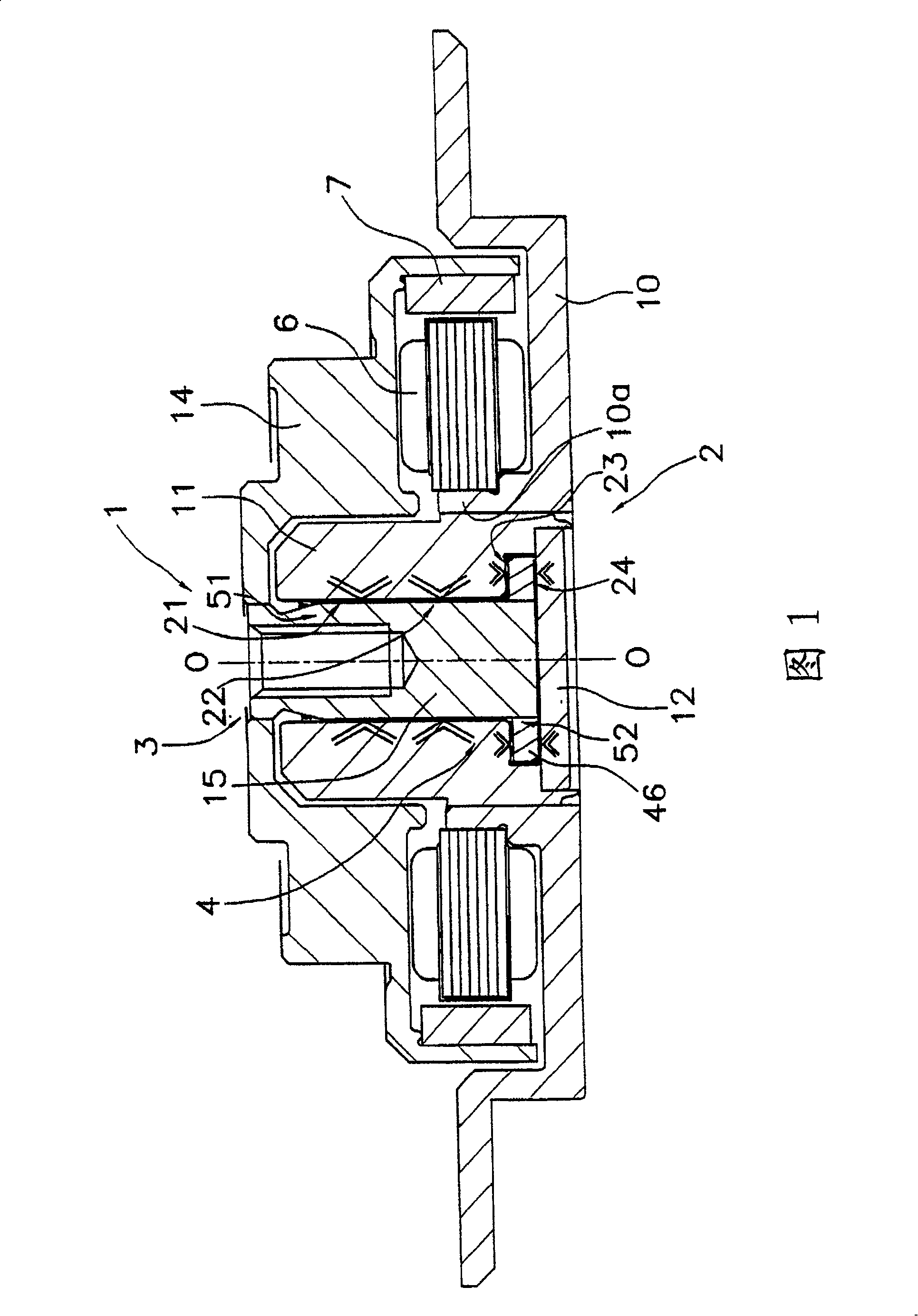

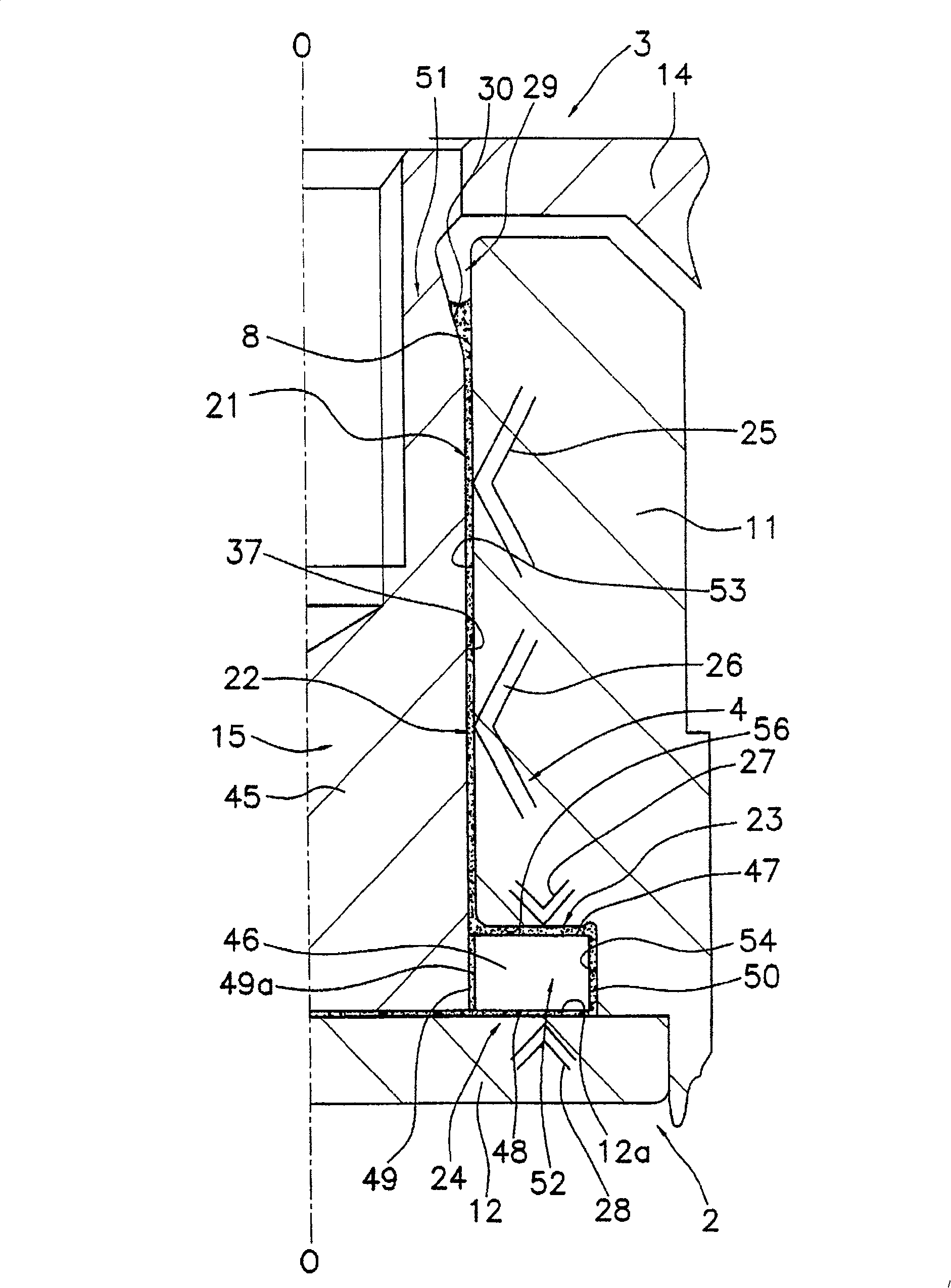

[0028] FIG. 1 is a vertical sectional view schematically showing a simplified structure of a spindle motor 1 in an embodiment of the present invention. A spindle motor 1 is configured to drive a recording disk such as a hard disk or the like to rotate, and is a part of a recording disk drive device.

[0029] In this embodiment, the line O-O shown in FIG. 1 is the rotation axis of the spindle motor 1 . In addition, in the description of this embodiment, for convenience, the vertical direction in FIG. 1 is set as "axial vertical direction", but this does not limit the direction of the spindle motor 1 in the actual installation situation.

[0030] In FIG. 1 , a spindle motor 1 mainly includes a fixed member 2 , a rotating member 3 and a bearing mechanism 4 . The bearing mechanism 4 supports the rotating member 3 on the fixed member 2 so that the rotating member 3 can freely rotate in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com