Microwave carbon-detection sensor uninfluenced by change of coal type

A sensor and microwave technology, applied in the field of microwave carbon measurement sensors, can solve problems such as the measurement range of ash blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The structure and working principle of the present invention will be described in detail below according to the embodiments.

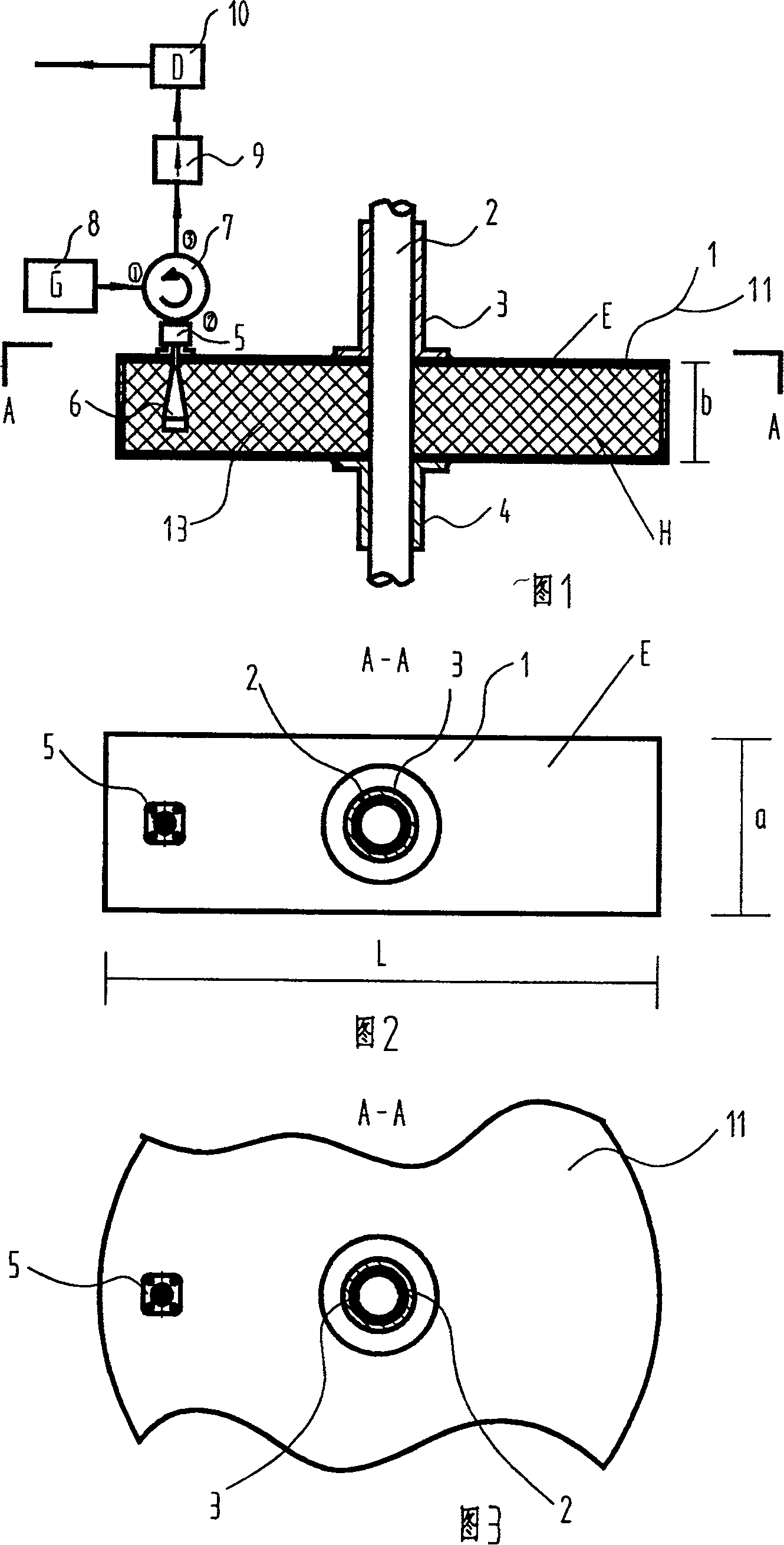

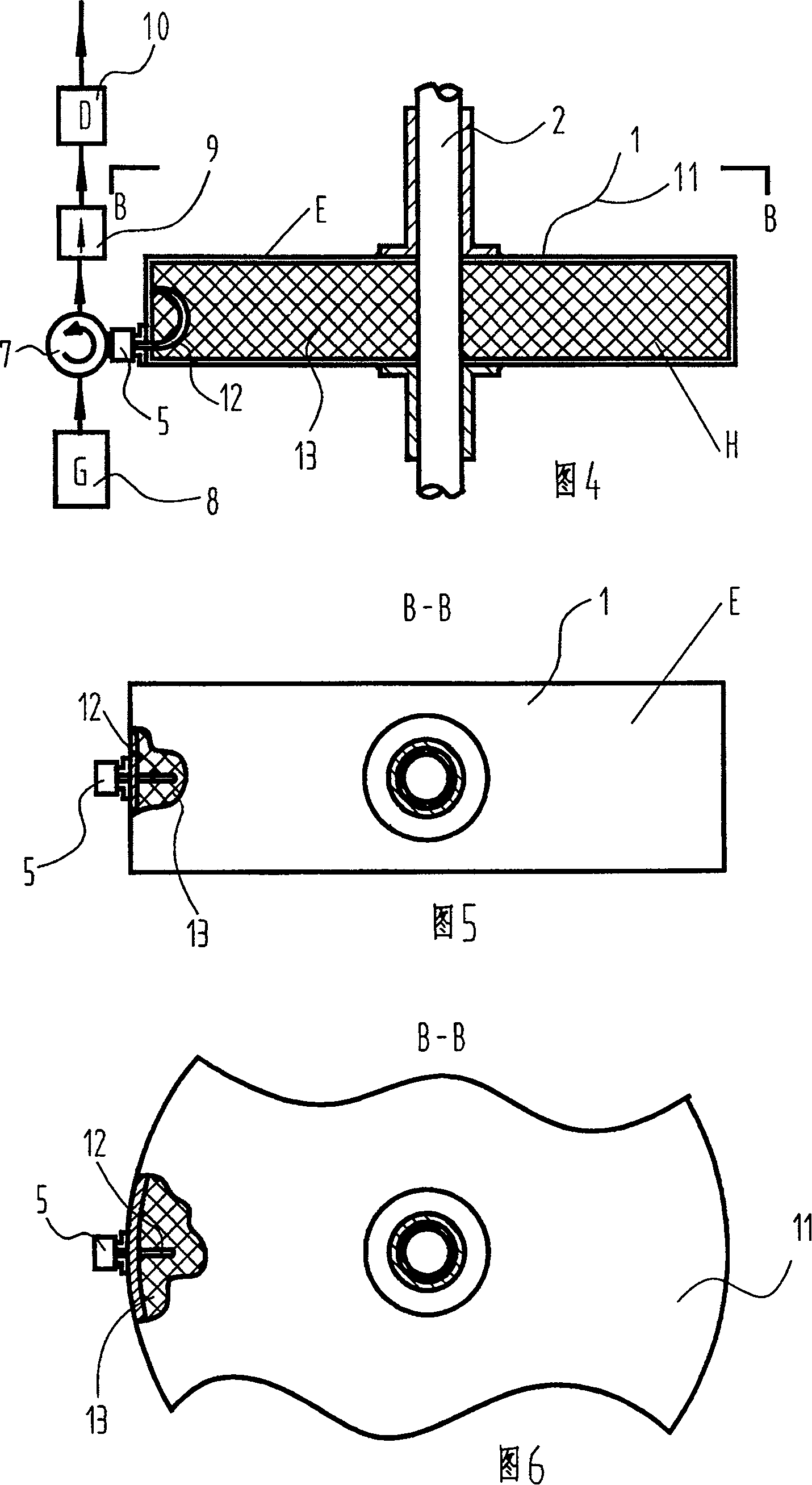

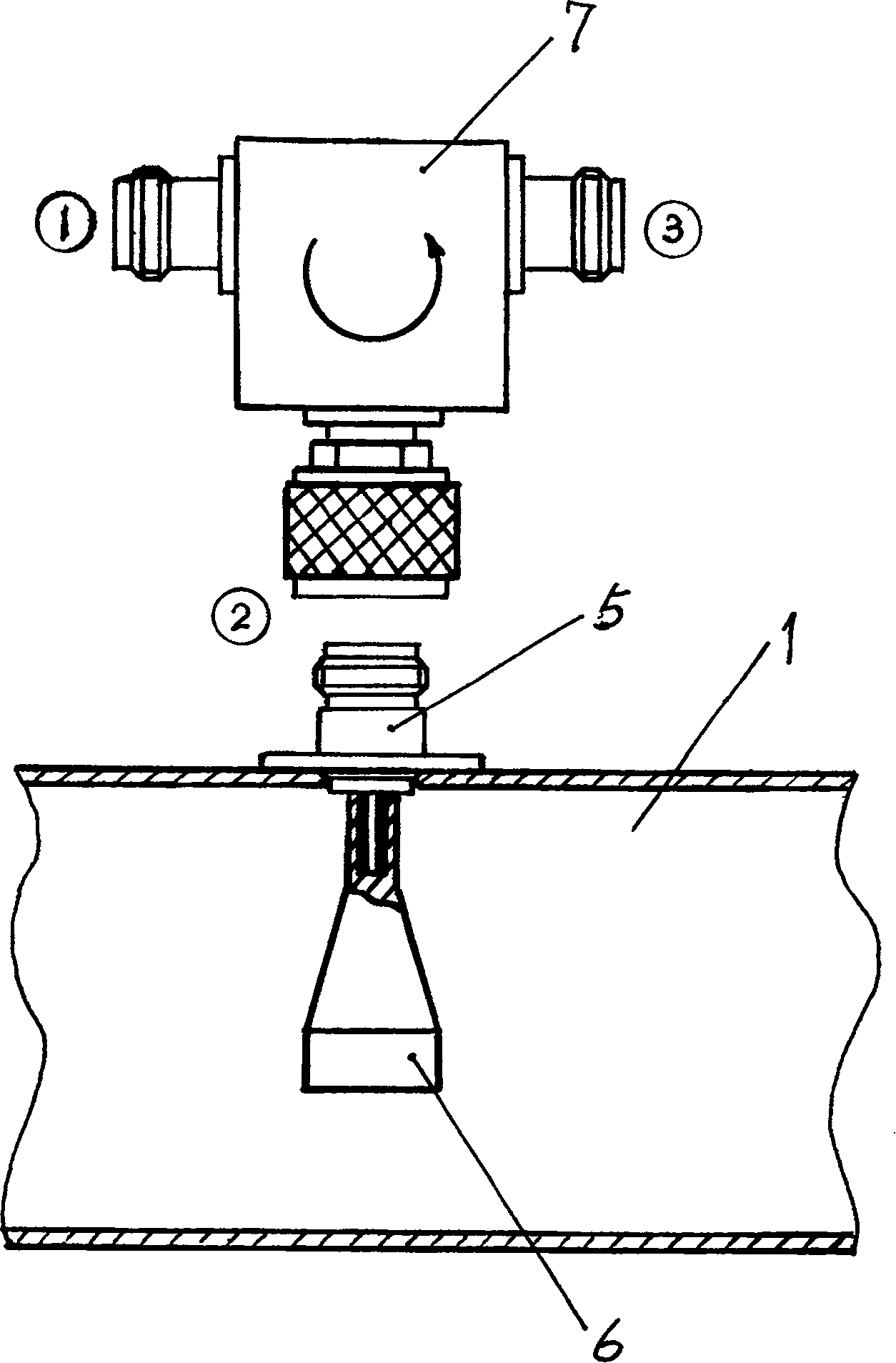

[0034] Referring to Figures 1, 2, and 7, part number 1 is the rectangular resonant cavity mentioned above, which can be composed of a section of rectangular waveguide with both ends closed, and a gray The sample tube 2, the gray sample tube is fixed on the resonant cavity 1 through the metal sleeves 3 and 4 on the upper and lower ends of the tube, wherein the metal sleeves 3 and 4 are also equivalent to the cut-off circular waveguide, which can prevent the microwave in the resonant cavity Leak along the upward and downward directions of the gray sample tube. The gray sample tube is generally a transparent quartz glass tube, and it is best to intersperse in the center of the E plane, that is, the position with the strongest standing wave field. On the E face of this rectangular resonant cavity, a described coaxial cable seat 5 is also housed, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com