Heat pump rectifying production process and plant for n-butyl acetate

A technology of butyl acetate and heat pump rectification, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of energy consumption, material consumption, etc. The effect of saving heating steam and cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

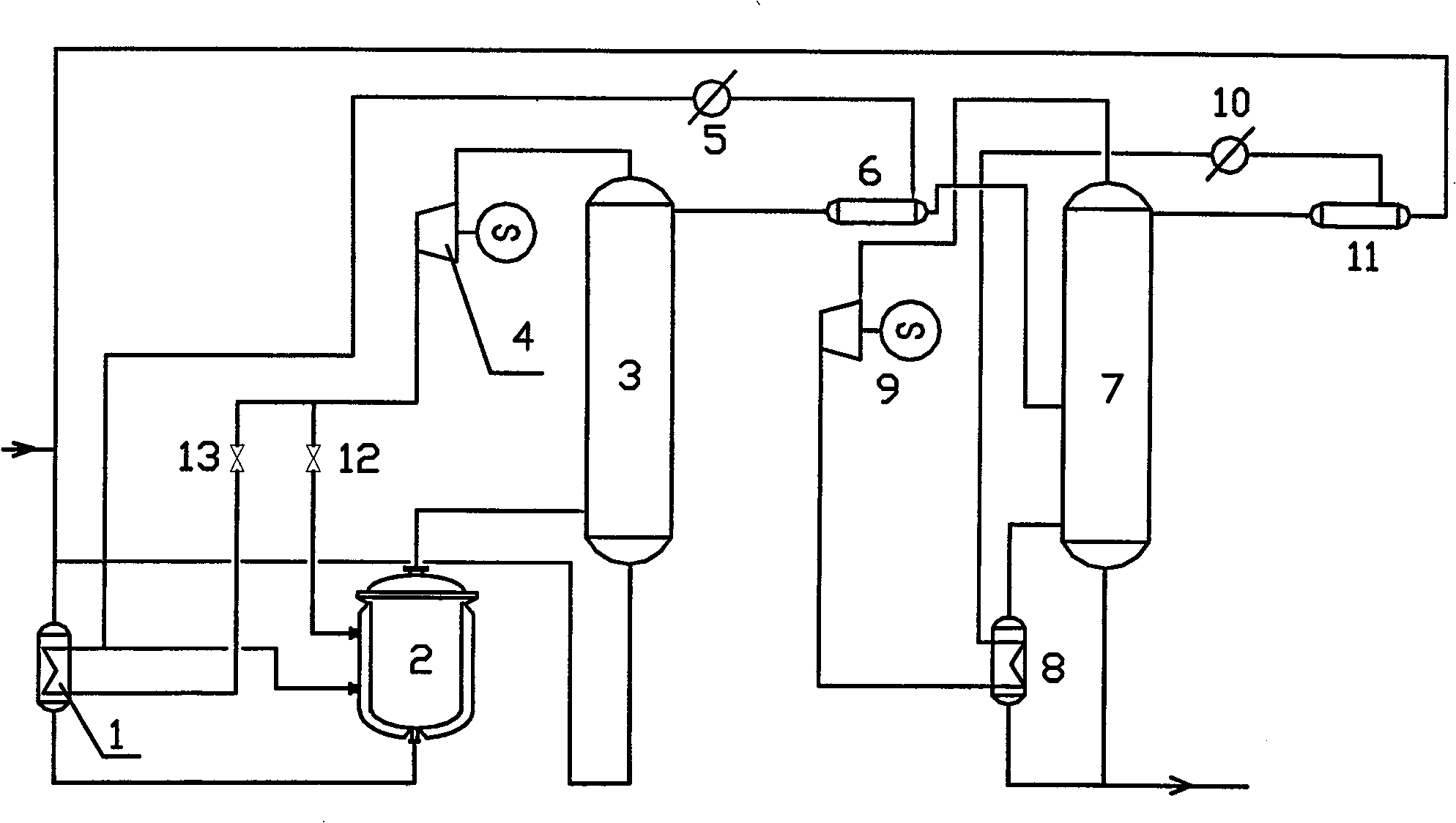

[0021] Embodiment 1 adopts figure 1 The device, the production process is as follows: the mixed gas from the top of the esterification tower is composed of 60% by weight of butyl acetate, 12% by weight of butanol and 26% by weight of water, the pressure is 0.103MPa, and the temperature is 91°C. After the mixed gas is compressed, its pressure is 0.309MPa and its temperature is 154°C.

[0022] The mixed gas from the top of the rectifying tower is composed of 39% by weight of butyl acetate, 49% by weight of butanol and 12% by weight of water, with a pressure of 0.103Mpa and a temperature of 114°C. After the compressed gas, its pressure It is 0.515Mpa, and the temperature is 180°C.

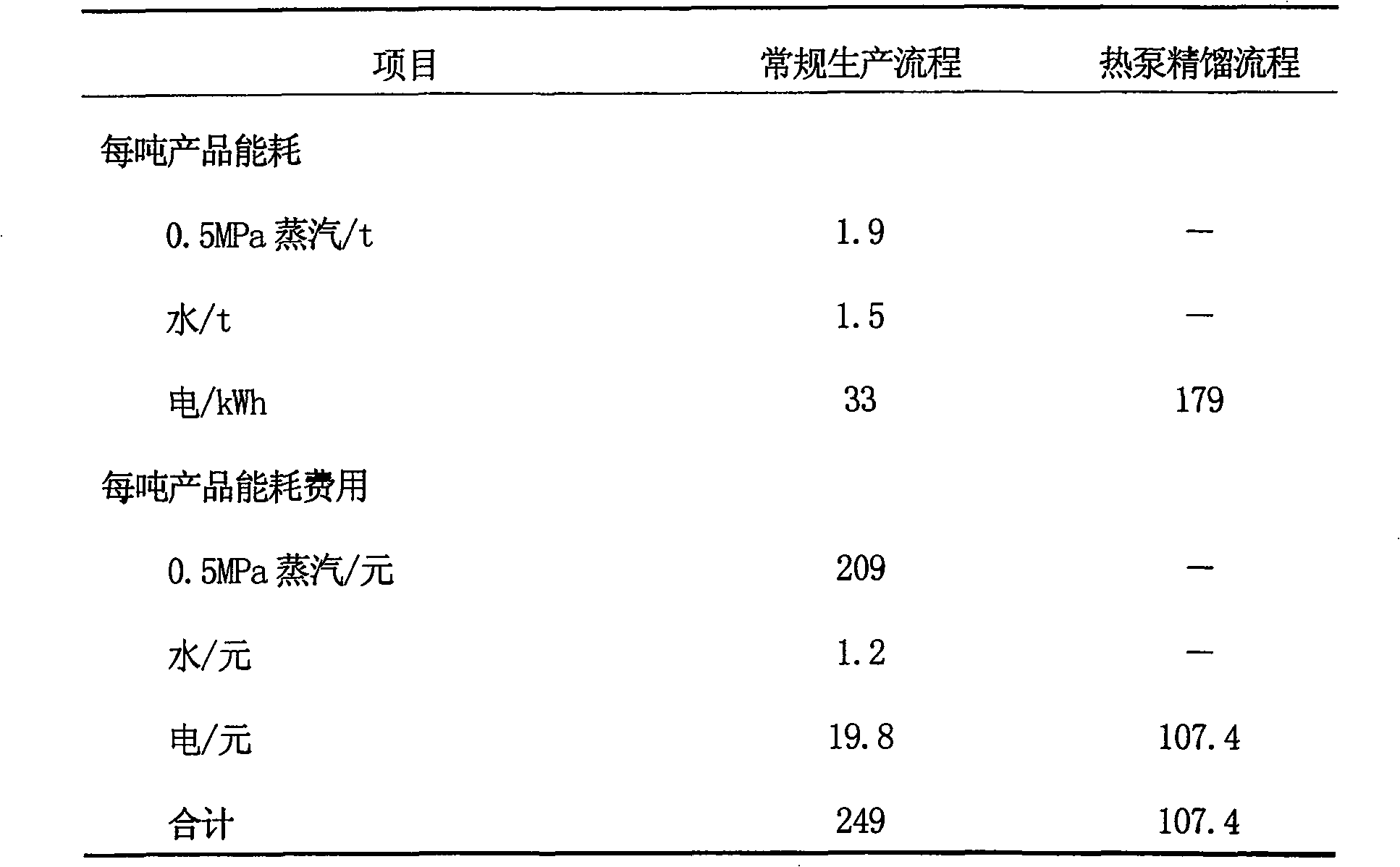

[0023] Compared with the conventional process, 141.6 yuan of energy consumption can be saved per ton of butyl acetate produced, and the specific energy savings are shown in Table 1.

[0024] Table 1

[0025]

[0026] Among them: steam is calculated at 110 yuan / t, electricity is calculated at 0.6...

Embodiment 2

[0027] Embodiment 2 adopts figure 1 The device, the production process is as follows: the mixed gas from the top of the esterification tower is composed of 64% by weight of butyl acetate, 8% by weight of butanol and 30% by weight of water, its pressure is 0.103MPa, temperature 91 ~ 93 ℃, After the gas mixture is compressed, its pressure is 0.309MPa and its temperature is 154°C.

[0028] The mixed gas from the top of the rectifying tower is composed of 39% by weight of butyl acetate, 49% by weight of butanol and 12% by weight of water, with a pressure of 0.103Mpa and a temperature of 114°C. After the mixed gas is compressed, its pressure It is 0.515Mpa, and the temperature is 180°C.

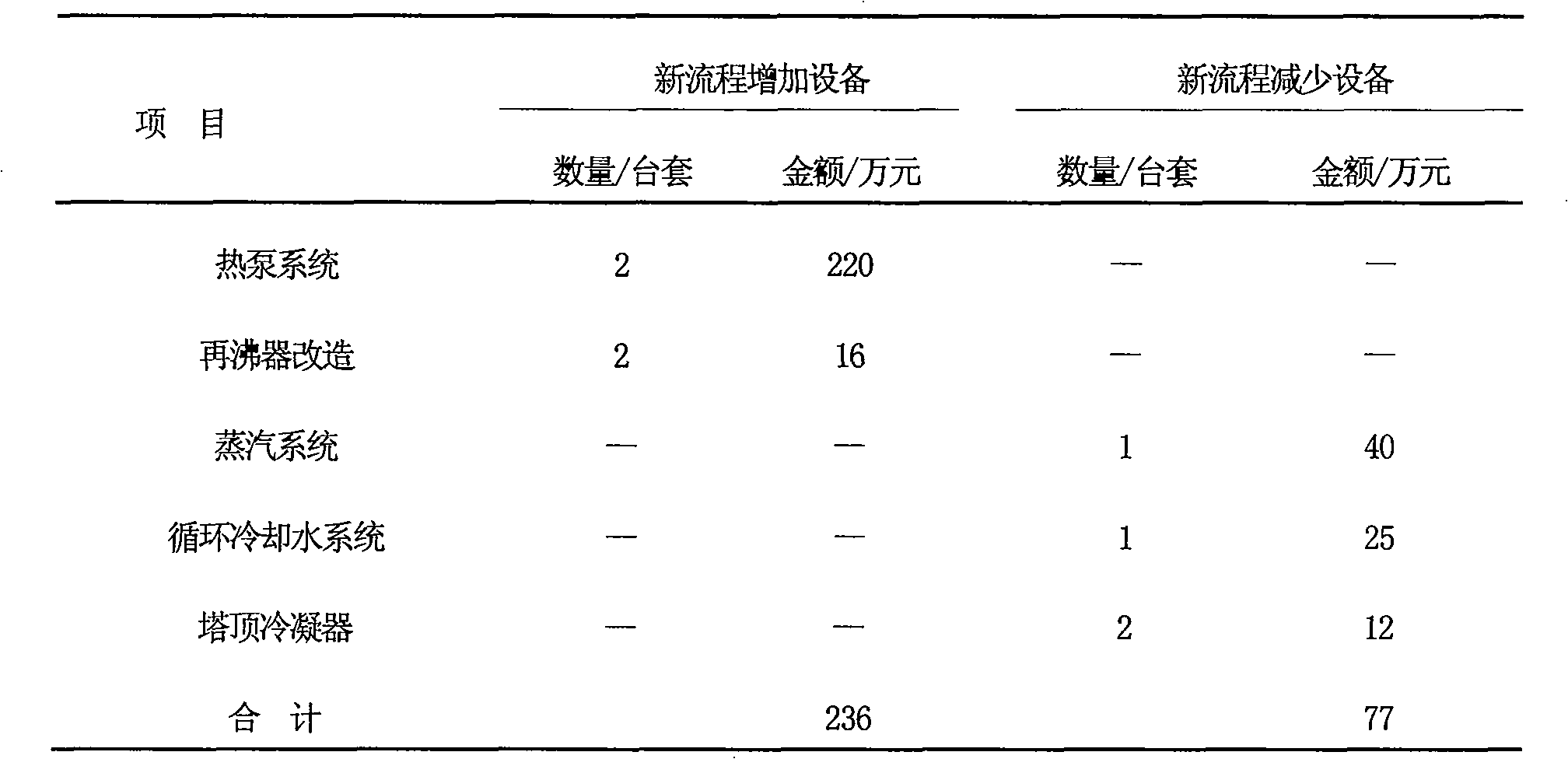

[0029] Compared with the conventional process, two sets of heat pump systems need to be added, and at the same time, the steam boiler system, cooling water circulation system and two tower top condensers are omitted. Since the azeotrope mixture gas is used as the working medium, the total heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com