Iron tower for power transmission

A technology for power transmission and transformation lines and towers, applied in towers, building types, buildings, etc., can solve problems such as the inability to easily identify the phase sequence and loop of the line, the inability to reduce the stress corrosion of the tower, the operation hazards of the transmission line, etc., and achieve bright colors. , Prevent biohazard towers, improve the effect of anti-corrosion aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

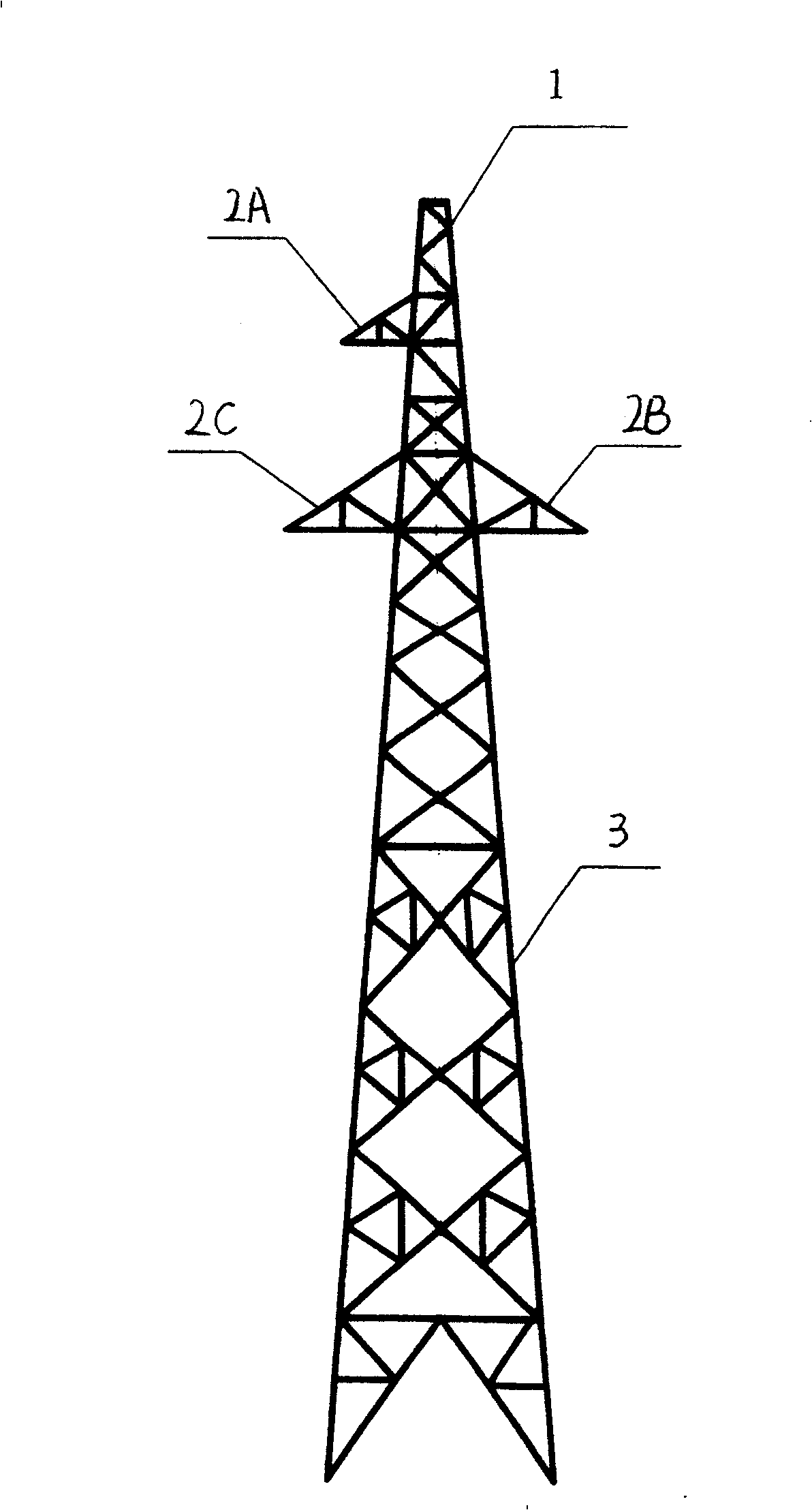

[0022] figure 1 For the iron tower of the single-circuit up-shaped power transmission and transformation line shown, the tower head 1 is coated with red coating, the cross-arm part 2A of the phase A circuit is coated with yellow coating, the cross-arm part 2B of the phase B circuit is coated with red coating, and the phase C The cross-arm part 2C of the circuit is coated with green coating, and other parts of the iron tower are not coated with colored coating.

Embodiment 2

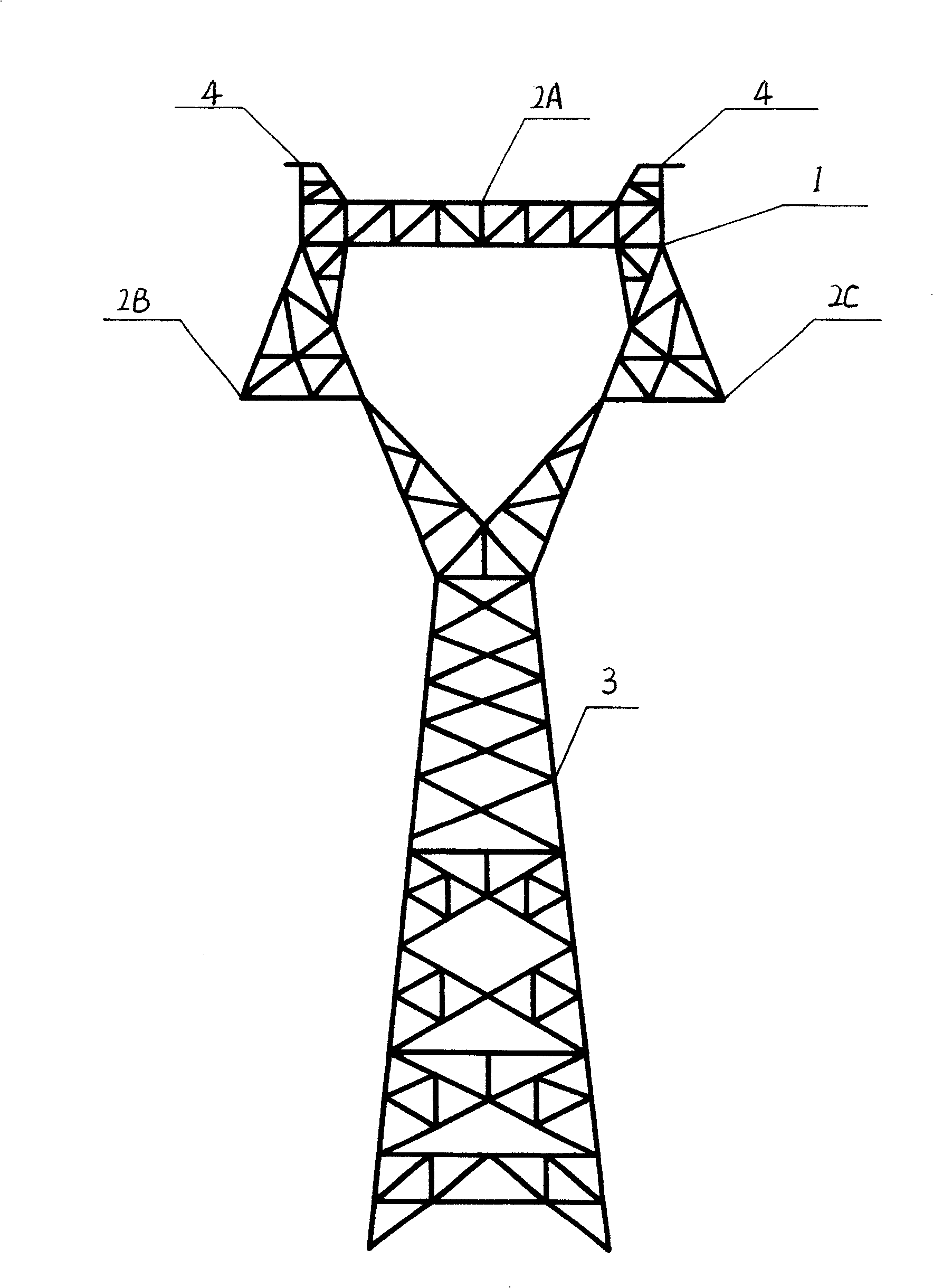

[0024] figure 2 In the single-circuit cat head-shaped power transmission line tower shown, the crossarm 4 of the lightning protection line and the tower head 1 are coated with red coating, the crossarm part 2A of the phase A circuit is coated with yellow coating, and the crossarm part 2B of the phase B circuit is coated with yellow coating. Red coating, the cross-arm part 2C of the C-phase circuit is coated with blue coating, and the tower body 3 is painted alternately with yellow, red and blue coatings from five meters above the ground to the cross-arm 2B and 2C sections. The tower body 3 is not coated with color coating from the ground to the five meter section apart from the ground.

Embodiment 3

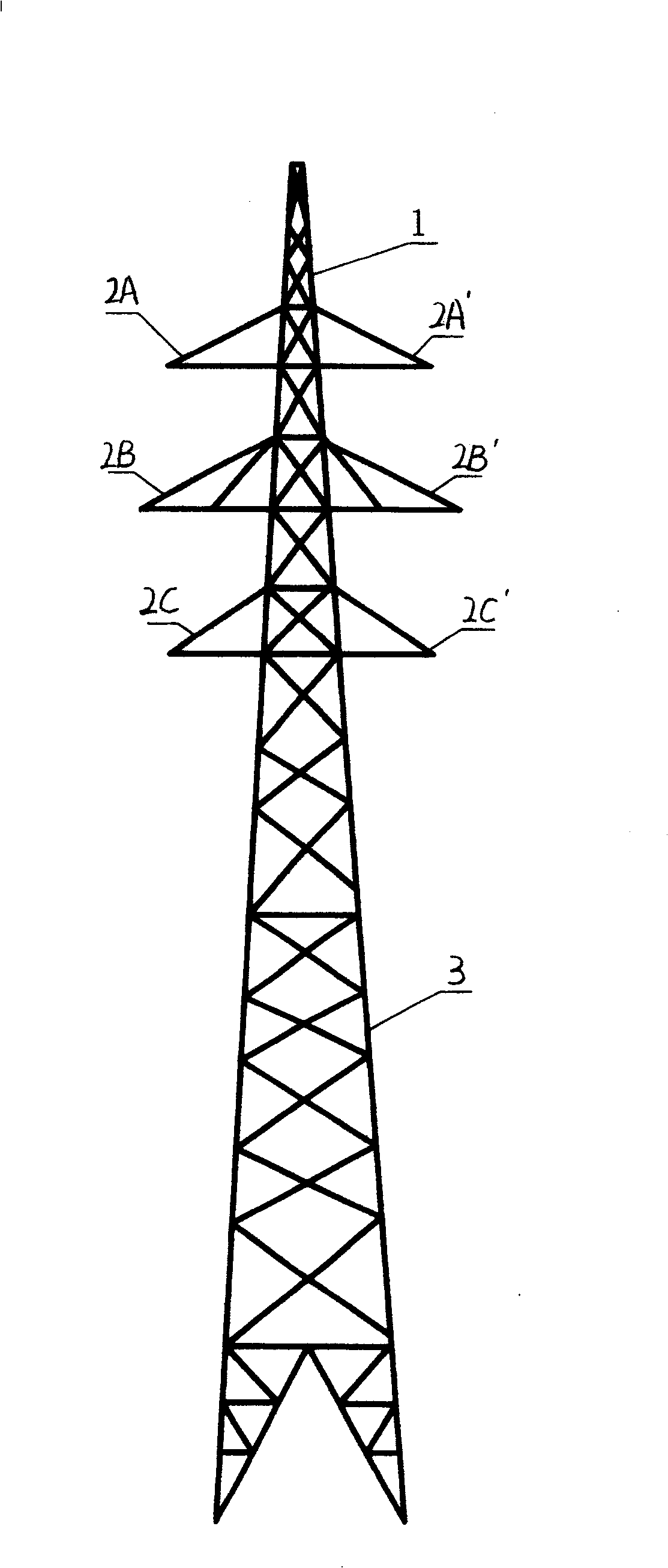

[0026] image 3 For the iron tower of the double-circuit power transmission line shown, the tower head 1 is coated with red coating, the cross arm part 2A of the phase A circuit is coated with yellow coating, the cross arm part 2B of the phase B circuit is coated with red coating, and the cross arm part 2B of the phase C circuit is coated with red coating. The arm part 2C is coated with green coating, the cross-arm part 2A' of the other circuit of the A-phase circuit is coated with yellow and red coatings, the cross-arm part 2B' of the other circuit of the B-phase circuit is coated with green and red coatings, and the other circuit of the C-phase circuit is coated with green and red coatings. The crossarm part 2C' of the primary circuit is coated with green and yellow coatings, and the tower body 3 is alternately painted with red, yellow and green coatings from the five meters above the ground to the crossarms 2C and 2C'. 3 Paint in green and yellow colors from the ground to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com