Rotary shell part hydraulic expansion integrating device

An integrated device, hydraulic bulging technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost and complex structure, and achieve the effect of reducing cost, reducing production energy consumption, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

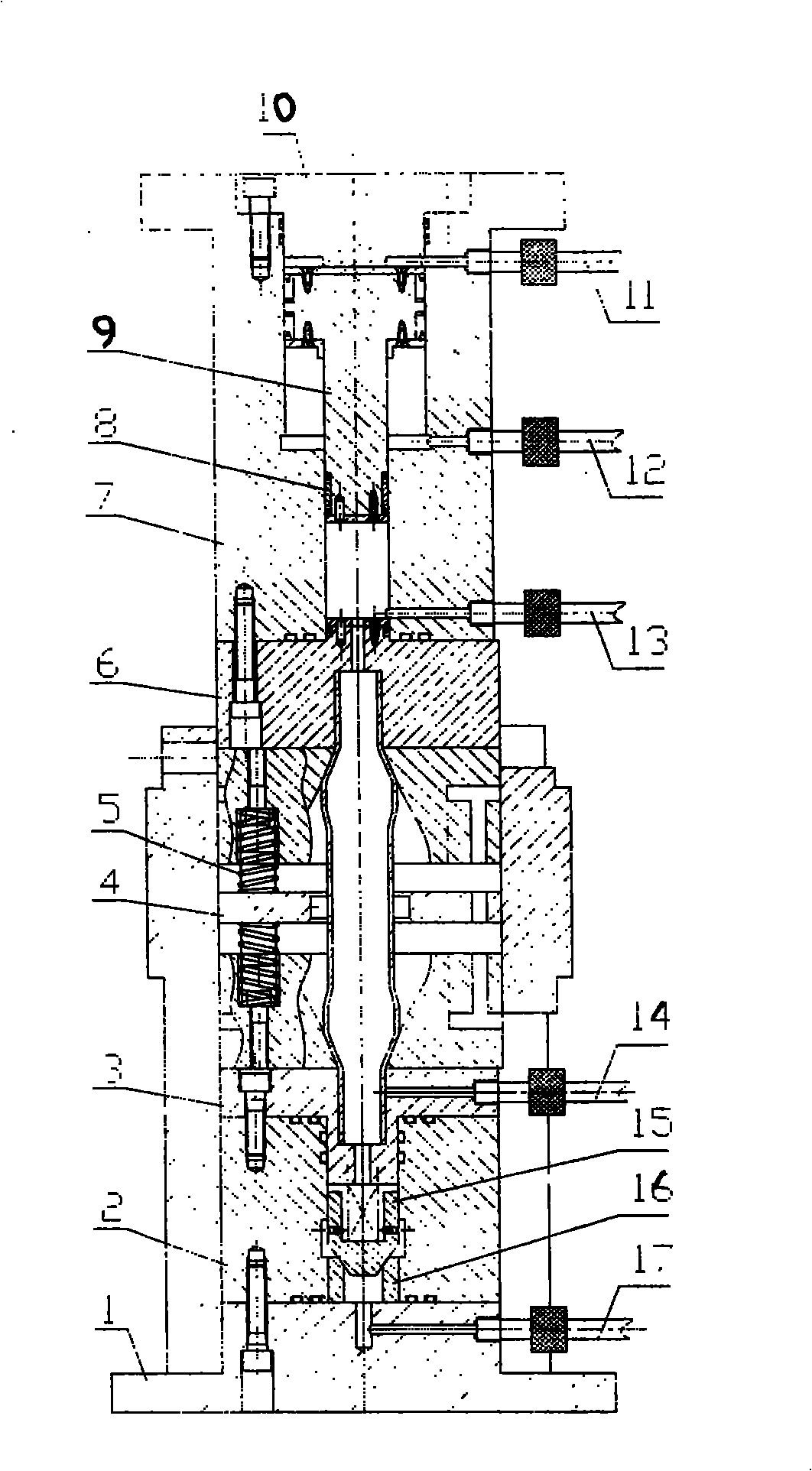

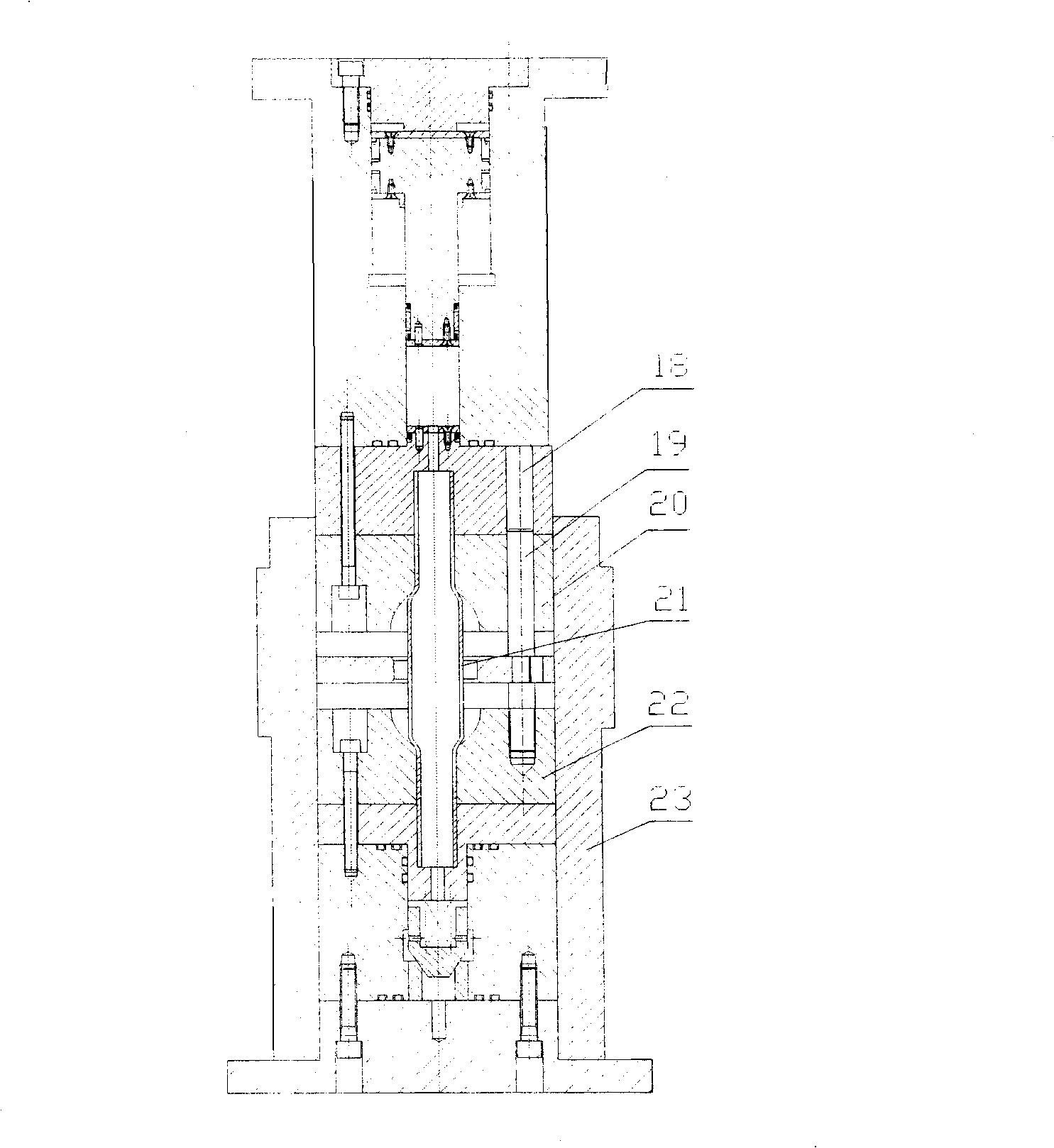

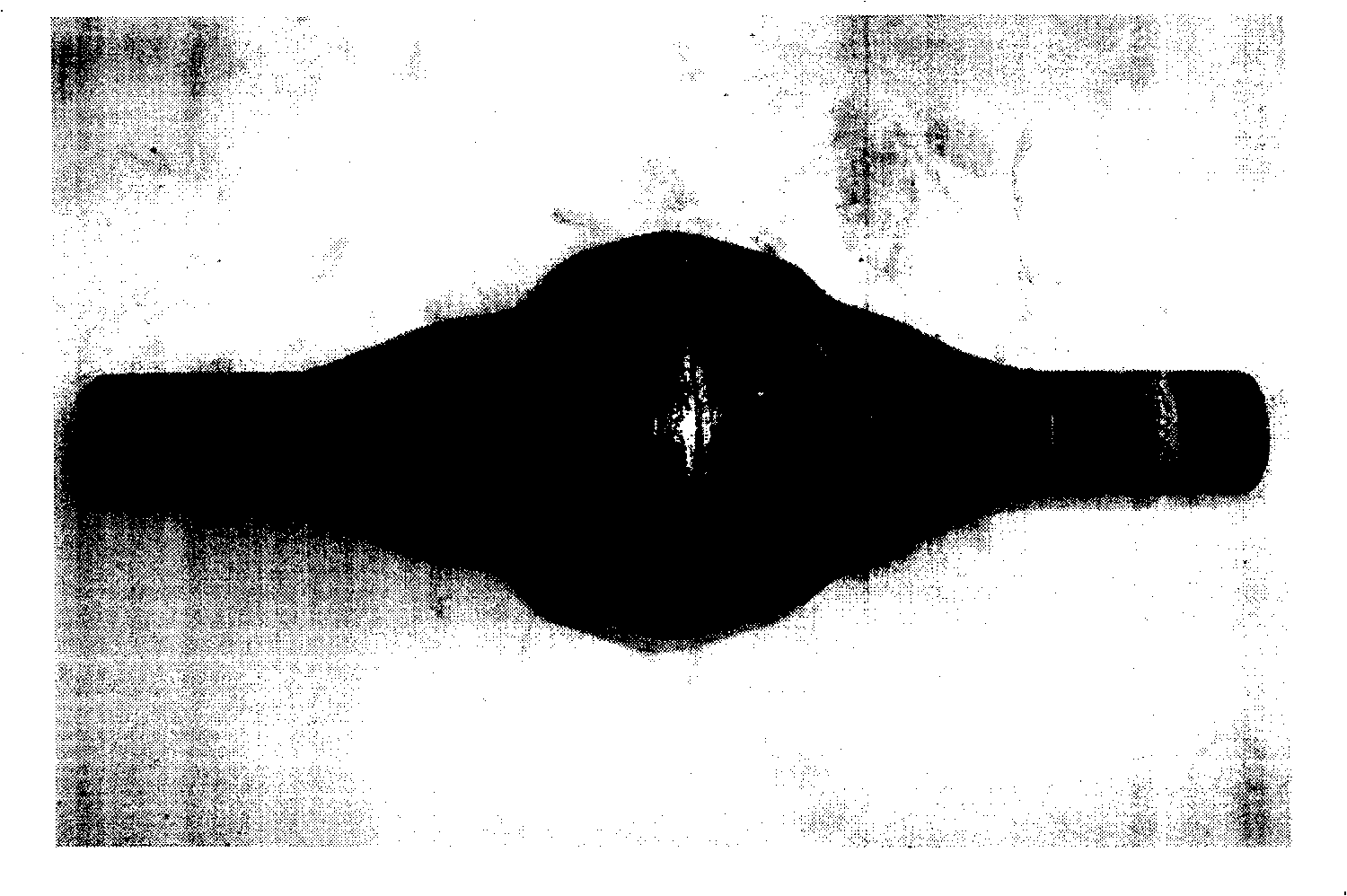

[0015] exist figure 1 , figure 2 It is an embodiment disclosed by the present invention. The mold system of the ultra-high pressure hydraulic bulging integrated device is composed of three parts: a supercharger, a liquid charger, and a sliding bulging mold. The bulging mold adopts a sliding type, and the horizontal parting mold is composed of a bulging upper mold 20, a bulging lower mold 22, a guide cylinder 23, and a control mold 4. The cavity of the bulging upper mold 20 and the bulging lower mold 22 is designed according to the profile of the bulging part, and the guide posts 19 on the lower mold and the guide holes 18 on the upper mold ensure the installation accuracy. The guide cylinder 23 ensures the guidance of the bulging upper mold and the bulging lower mold, and provides mold clamping force. If the bulging part adopts two bulging processes, during the first bulging, a control mold 4 needs to be installed between the bulging upper mold and the bulging lower mold to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com