A hull corrugating method and the hull formed therefrom

A ship hull and corrugating technology, which is applied to ship parts, ship construction, ships, etc., can solve the problems of no equipment, etc., and achieve the effect of easy operation, simple forming method and simple forming equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

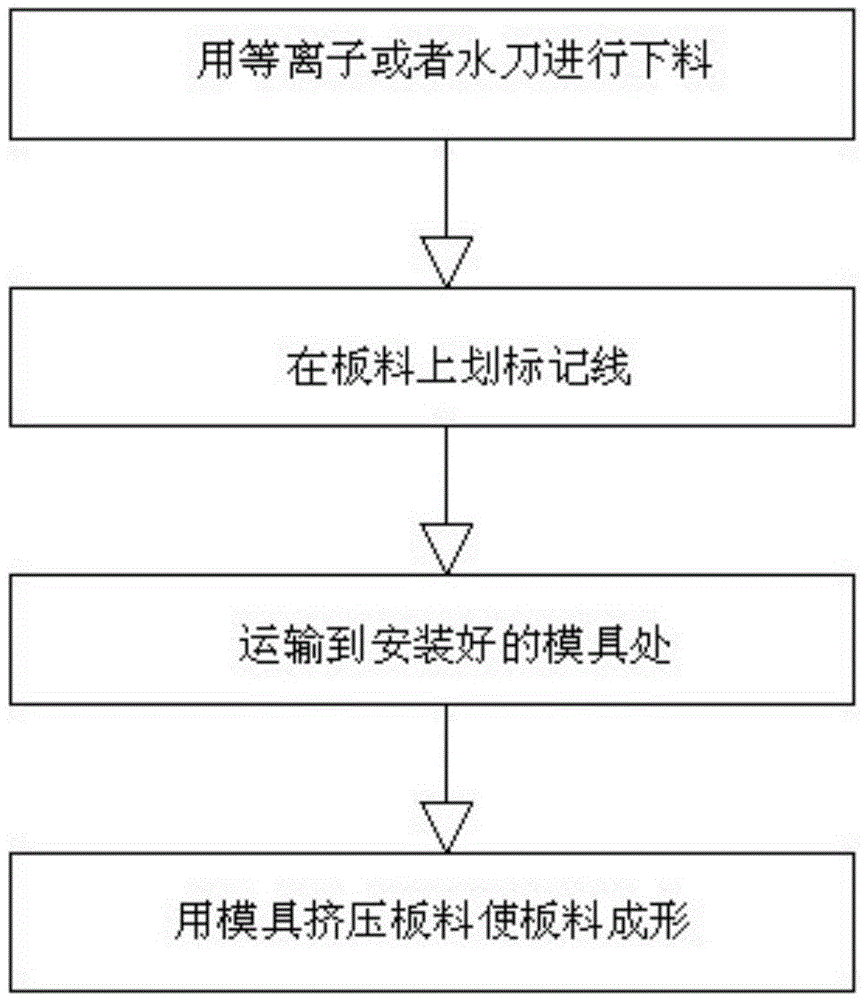

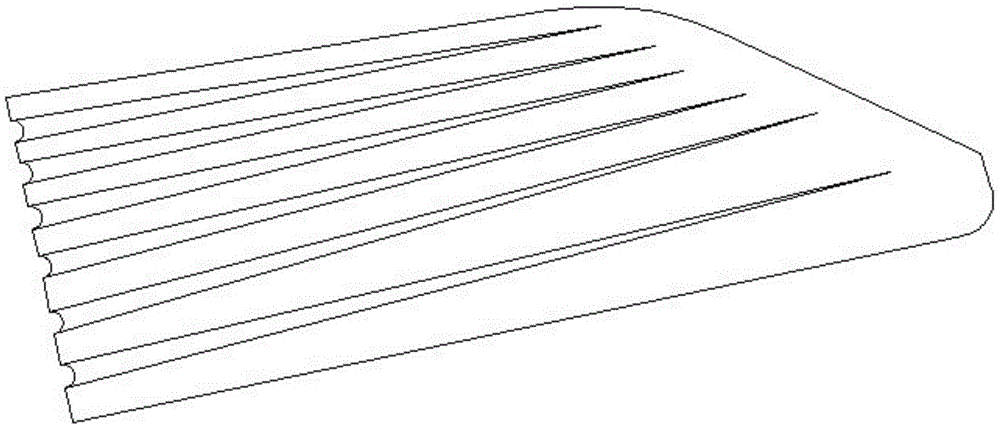

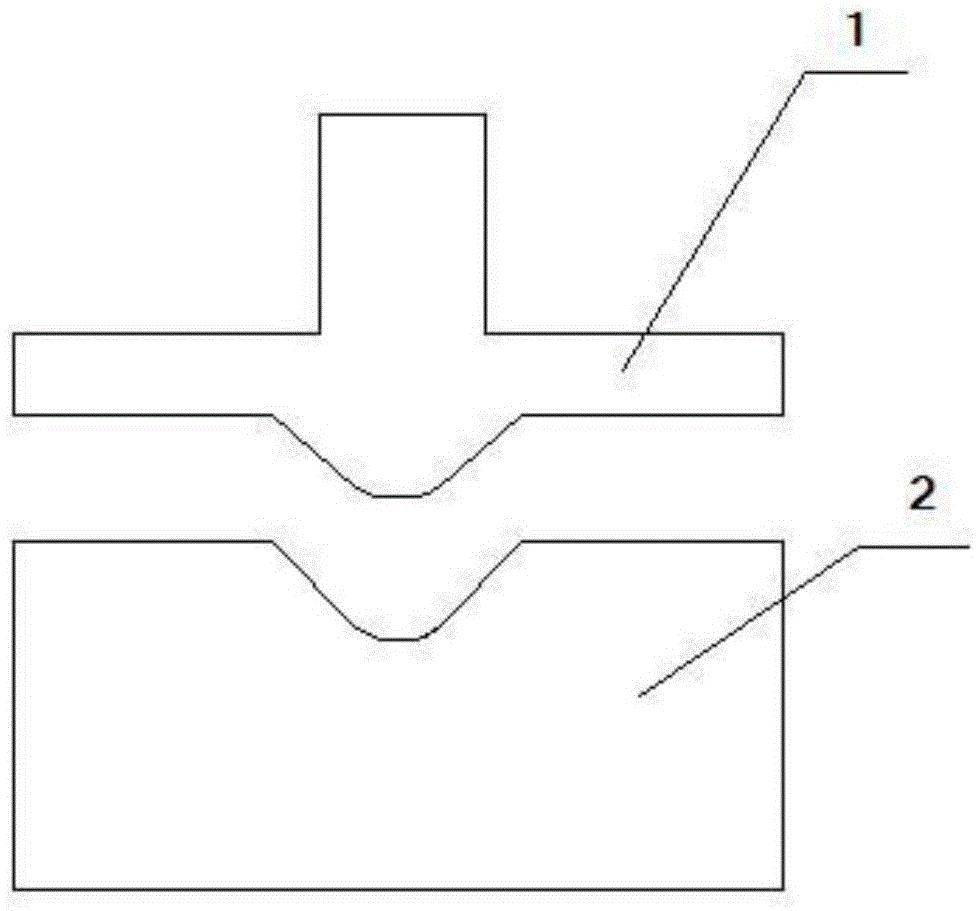

[0022] Such as figure 1 As shown, a hull corrugating method of the present invention, first adopts plasma or water knife to carry out blanking of sheet material, controls water knife through numerical control program in blanking process and draws on the position of both end surfaces corresponding to the axial center of corrugation on sheet material Such as Figure 6 As shown in the small triangle marking line, the triangular position of the small triangle marking line at both ends of the sheet corresponds to the position of the axial centerline of the corrugation to be pressed; At the side plate corrugation forming mold, the corrugation of the hull bottom plate and the corrugation of the hull side plate are pressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com