Magnetic control sintering molding device and method

A technology of sintering molding and magnetic control, applied in ceramic molding machines, manufacturing auxiliary devices, processing and manufacturing, etc., can solve the problems of high specific cost, low strength of formed parts, expensive price, etc., and achieve the effect of low cost and simple forming equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

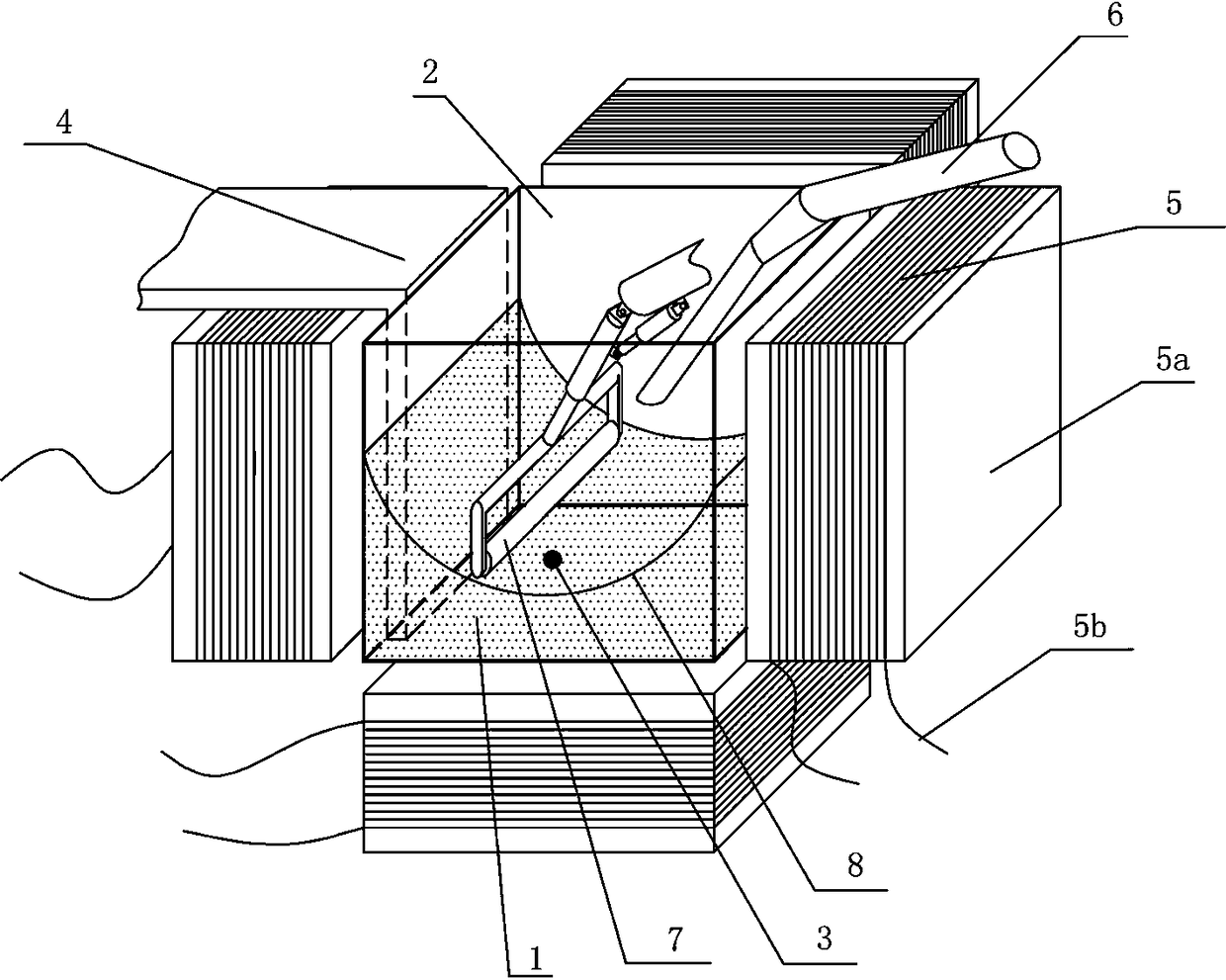

[0031] Such as figure 1 The magnetron sintering molding device shown includes a tank structure 2 for carrying powder 1, a magnetic sphere 3 that is in contact with powder 1 and sinters powder 1, and a pair of magnetic spheres 3 is arranged outside the tank structure 2. An electromagnetic heater 4 for heating, an electromagnet 5 for controlling the movement of the magnetic sphere 3 is installed outside the tank structure 2; an opening for adding powder 1 to the tank structure 2 is also provided Filling device 6; the magnetic sphere 3 is a magnetic ball;

[0032] The tank structure 2 is a cube structure, and its top surface is not closed; the number of the electromagnets 5 is 6, and their installation positions are respectively located on the six sides of the cube of the tank structure 2; One of the two electromagnets 5 facing each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com