Tapping assist fastening element and method

A technology for fixing elements and fixtures, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve the problems of complex design, increased end load, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

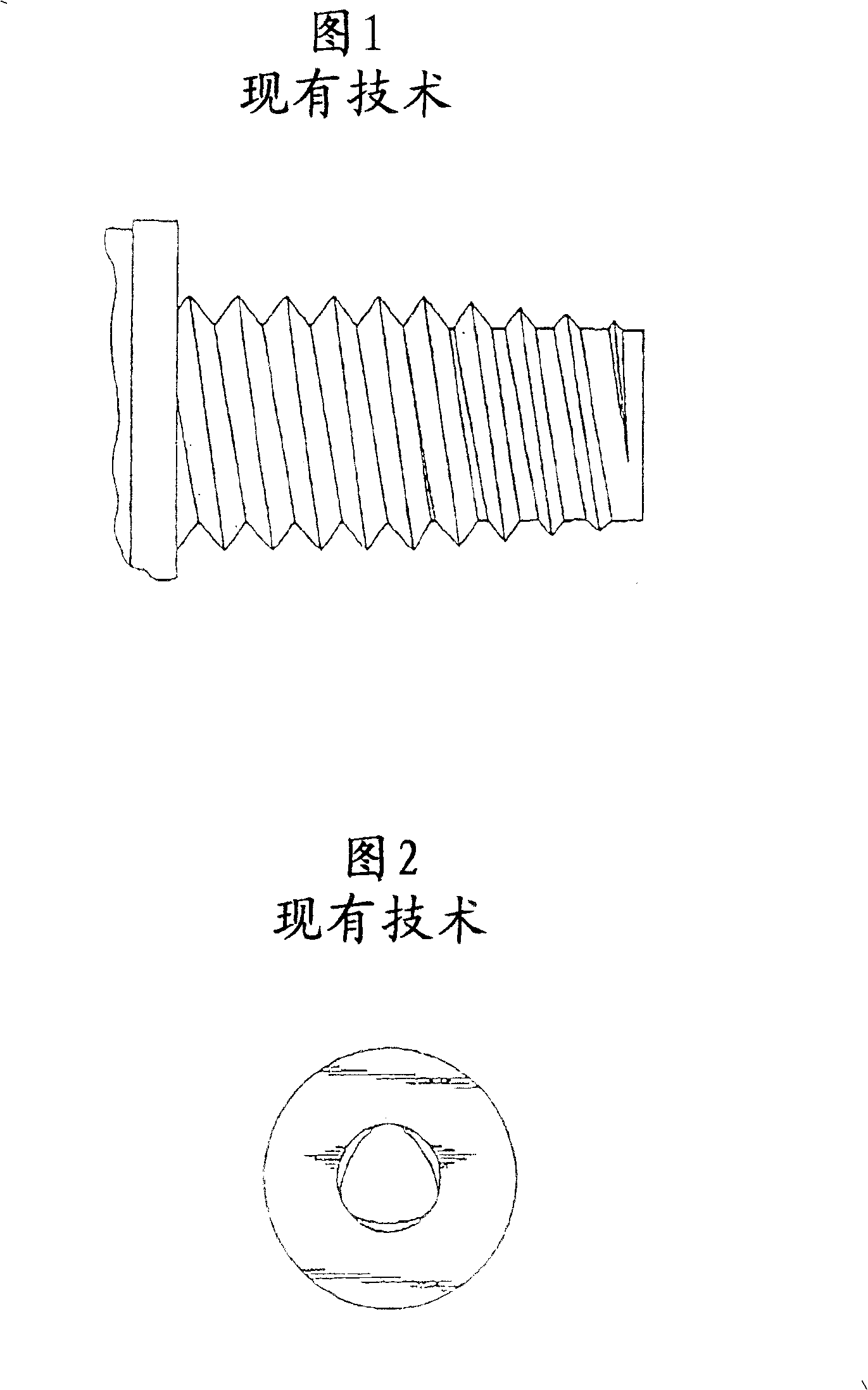

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

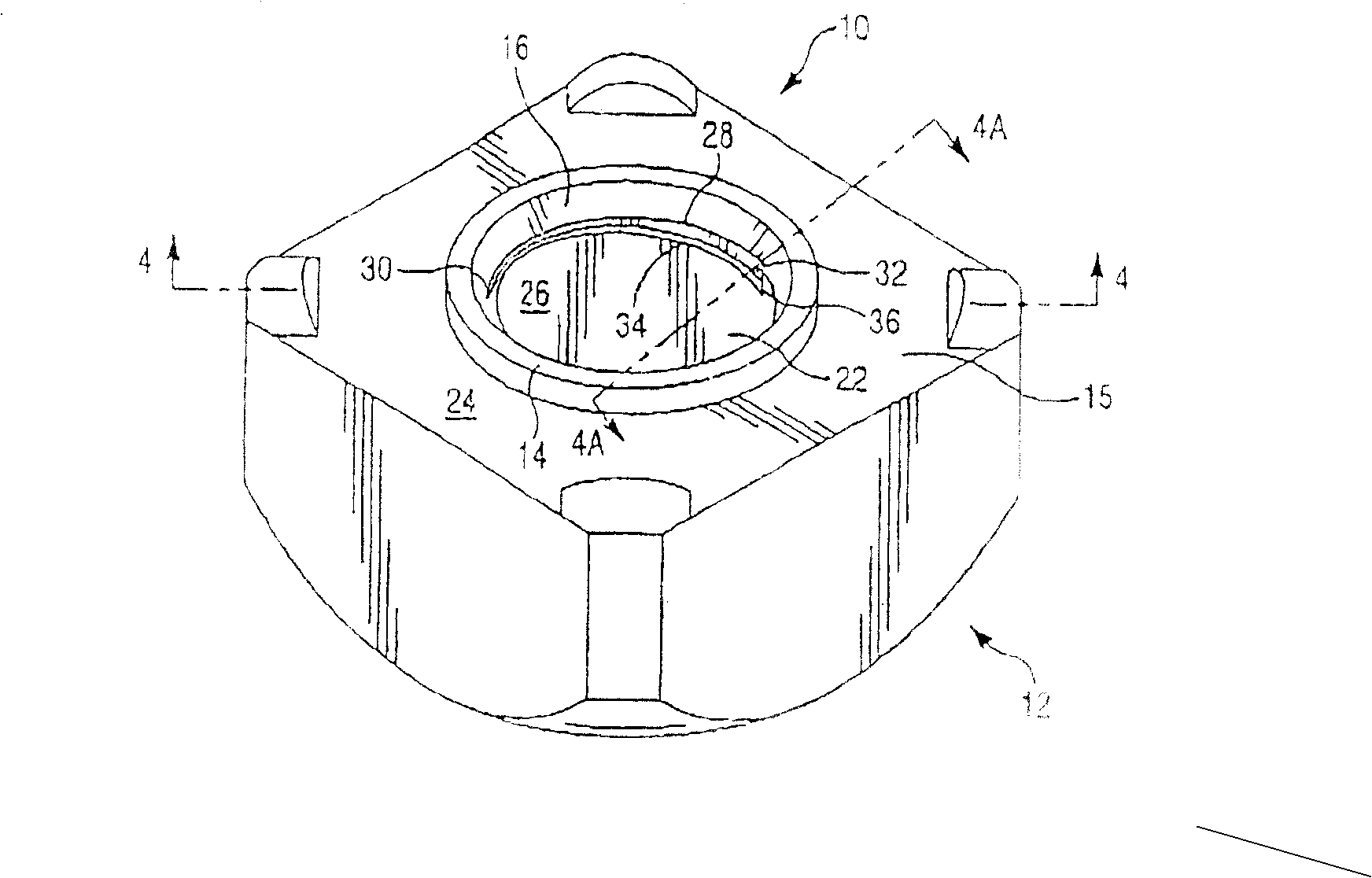

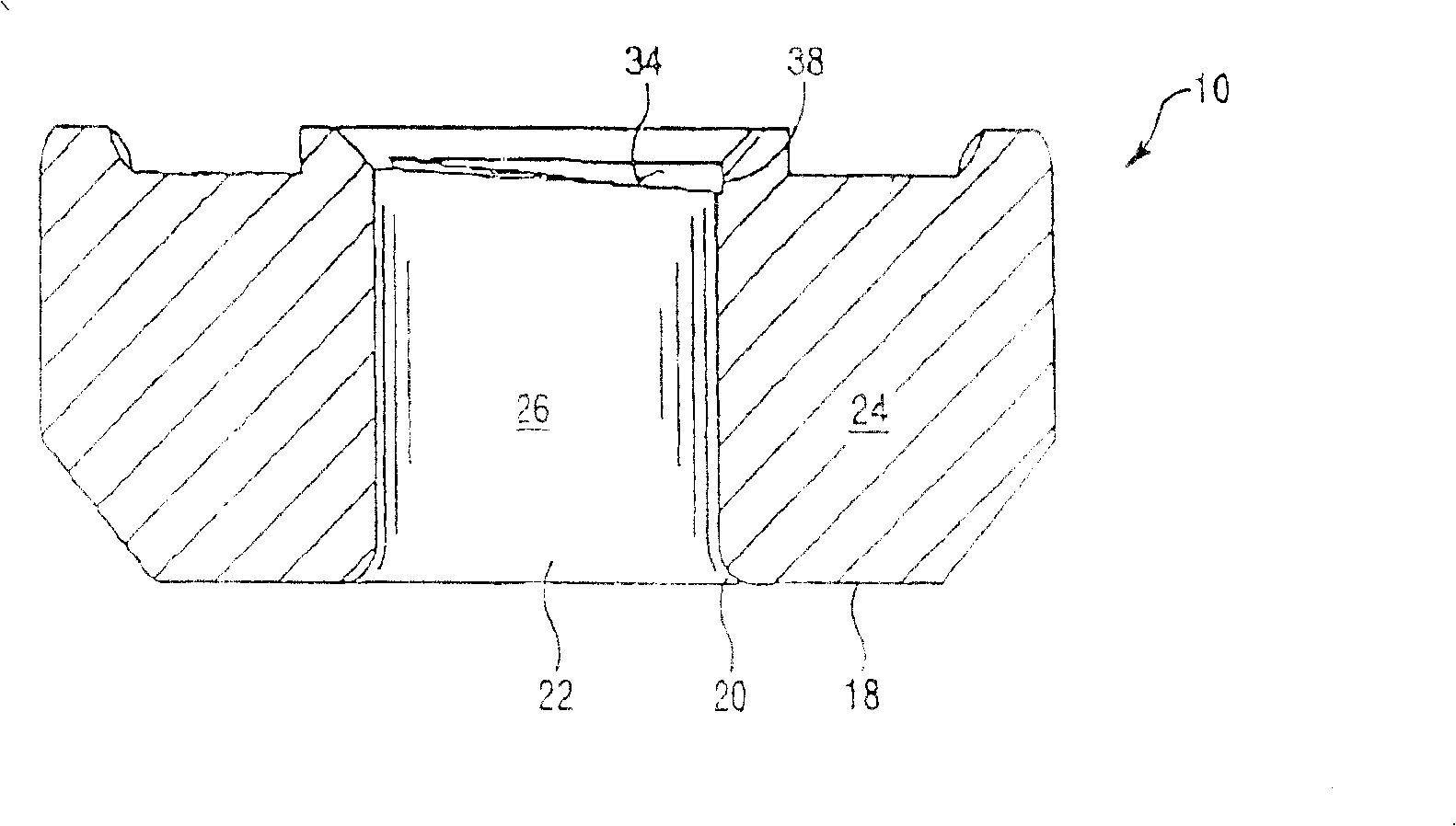

[0050] With reference to the accompanying drawings, especially Figure 3-4A and 9A-D, which show generally indicated at 10 an embodiment of the fixation element of the present invention. In this particular embodiment, the fixing element of the invention is in the shape of a weld nut 12 with a guide 14 . It should be understood that the structure and principles of the present invention are generally not limited to weld nuts, holders with guides or nuts, and that this embodiment is merely an example of the present invention, by means of a self-tapping holder or tap during the nut tapping process. Engagement, this example can be used with all unthreaded holes in retainers or castings that have internal threads formed therein. The fixing element of the present invention can also form a fixing assembly by engaging with all self-tapping fixings such as screws, bolts, studs and the like having a wide variety of different configurations. The figures and descriptions of the fixation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com