Ball spline

A technology of ball splines and balls, applied in bearings, linear motion bearings, bearing components, etc., can solve the problems of reduced section moment of inertia and unfavorable bending rigidity of spline shafts, so as to ensure bending rigidity, improve rigidity, and reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

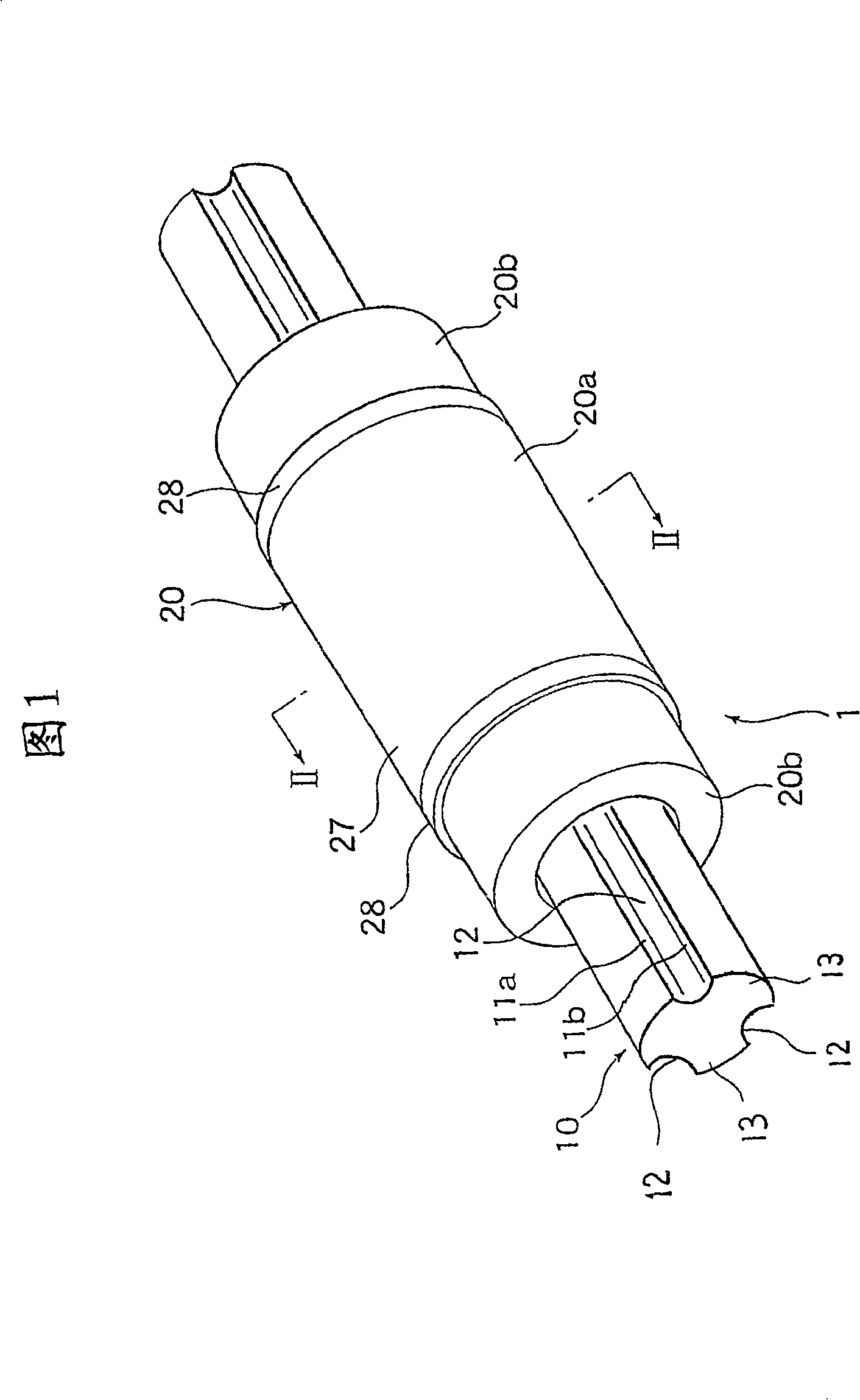

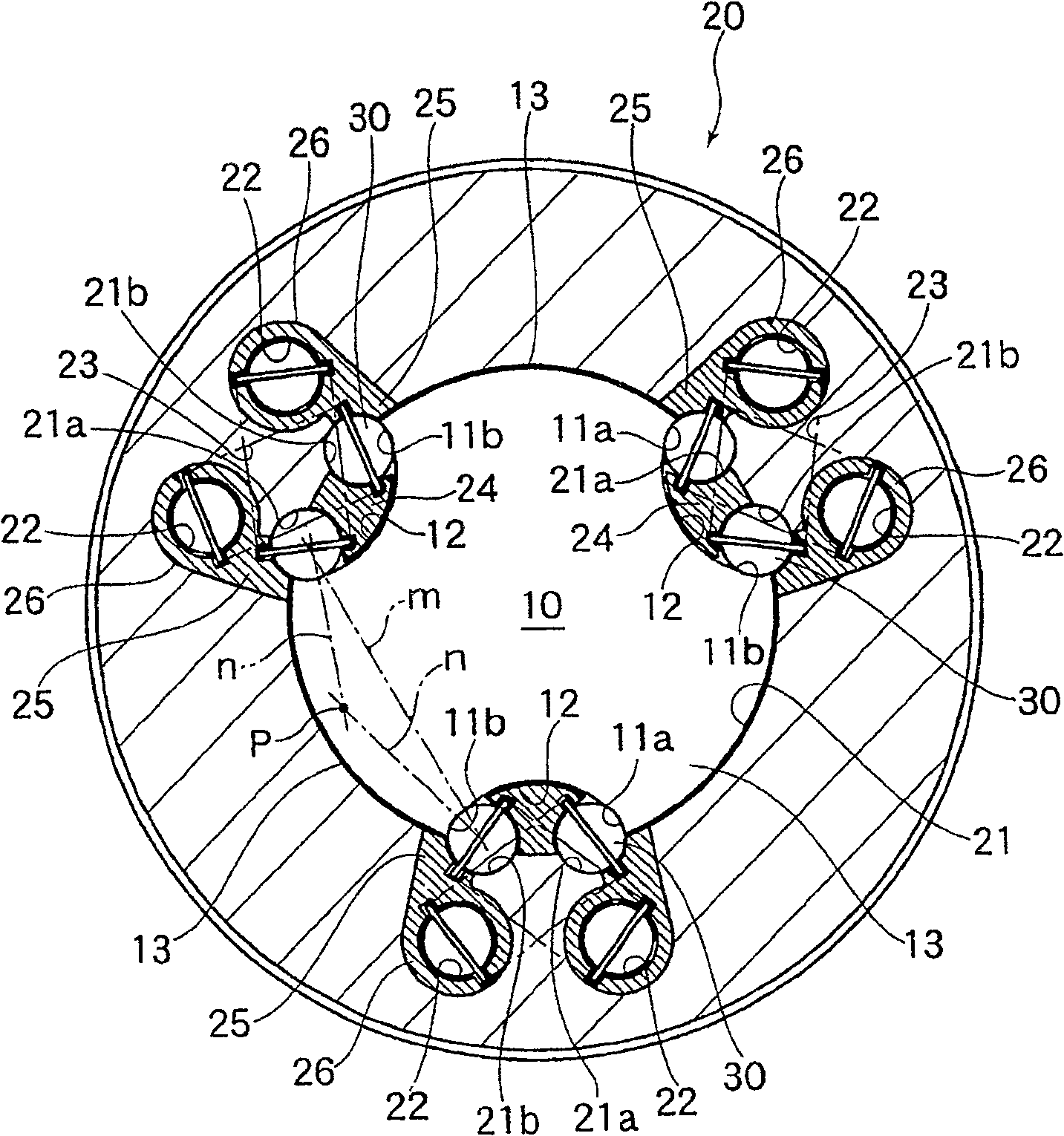

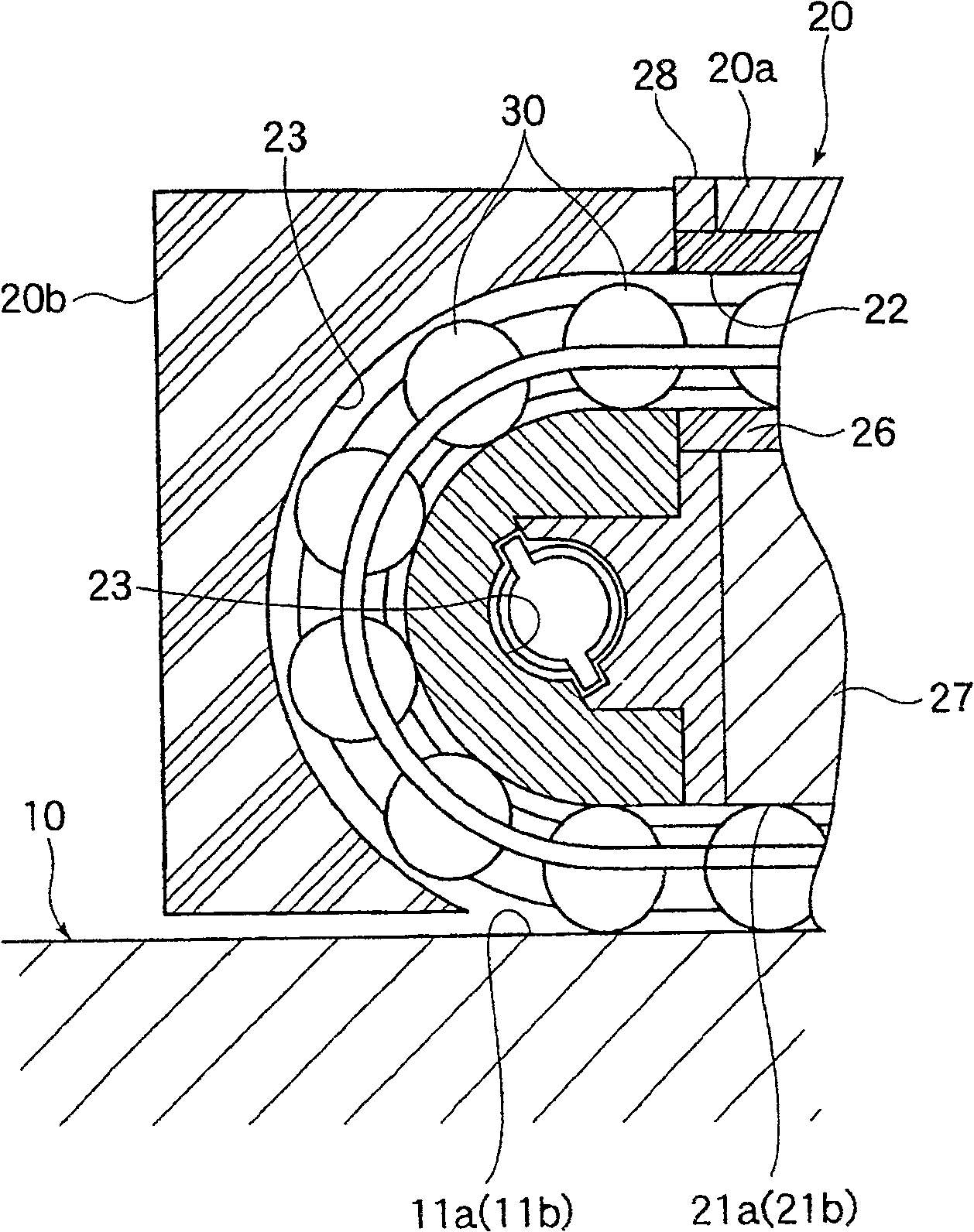

[0032] Next, the ball spline of the present invention will be described in detail using the drawings.

[0033] Figure 1 and figure 2 It is a front sectional view showing the first embodiment of the ball spline to which the present invention is applied. The ball spline 1 is composed of a spline shaft 10 and a spline nut 20, the spline shaft 10 is formed with a plurality of ball rolling surfaces 11a, 11b along the length direction; The hole 21 is formed in a substantially cylindrical shape.

[0034]The spline shaft 10 has a substantially circular cross-section, and three torque transmission grooves 12 are formed on its outer peripheral surface in the longitudinal direction. These torque transmission grooves 12 are arranged to divide the outer peripheral surface of the spline shaft 10 into thirds, and each torque transmission groove 12 is provided so as to cut the outer peripheral surface of the spline shaft 10 into an arc shape. On the outer peripheral surface of the spline s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com