8-box 9-layer high-temp calciner

A high-temperature calcination and coal calcination technology, which is applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve problems such as high production costs, large power consumption, and uneven furnace temperature, and achieve improved production environment and smoke blackness The effect of reducing and fully burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

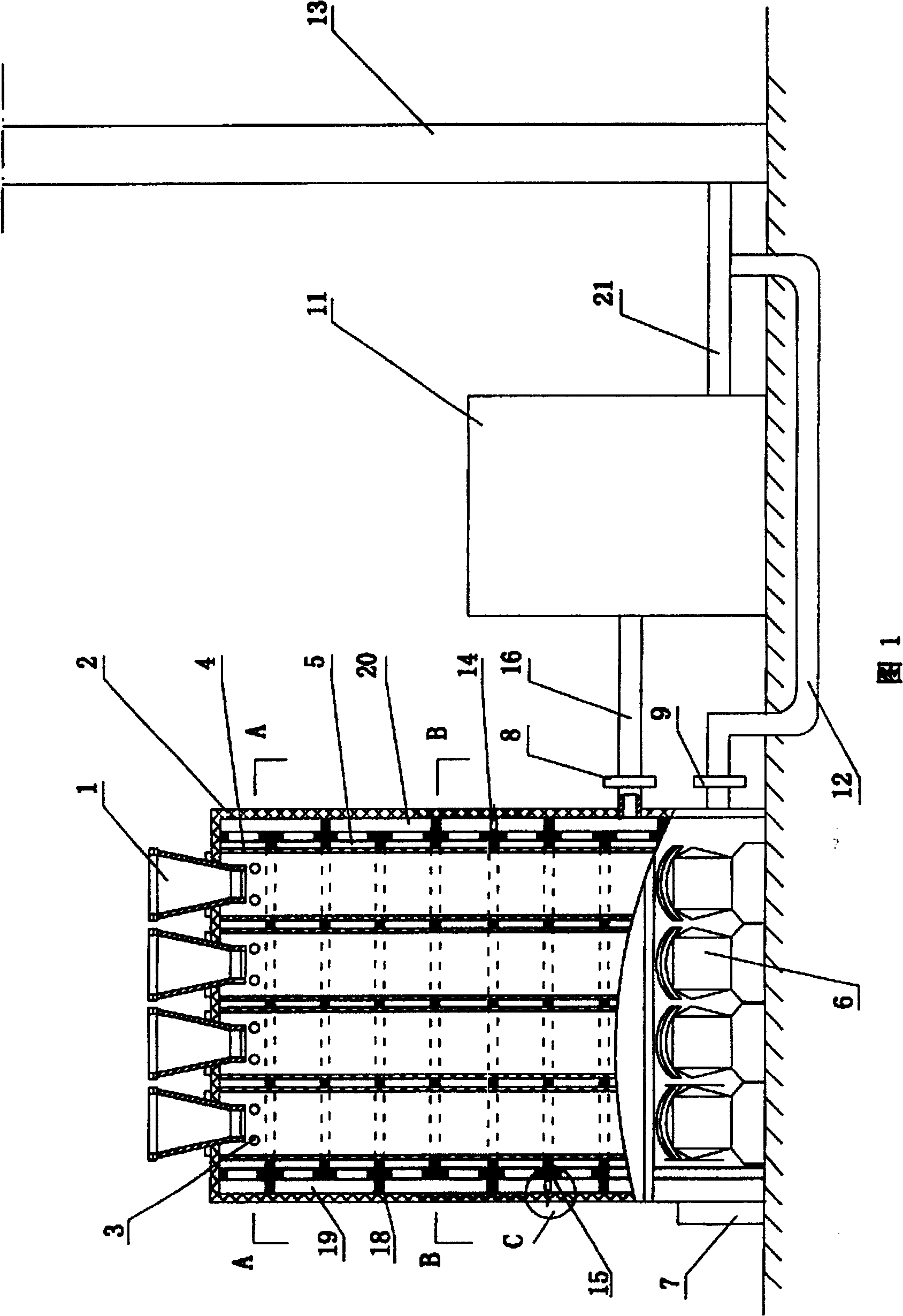

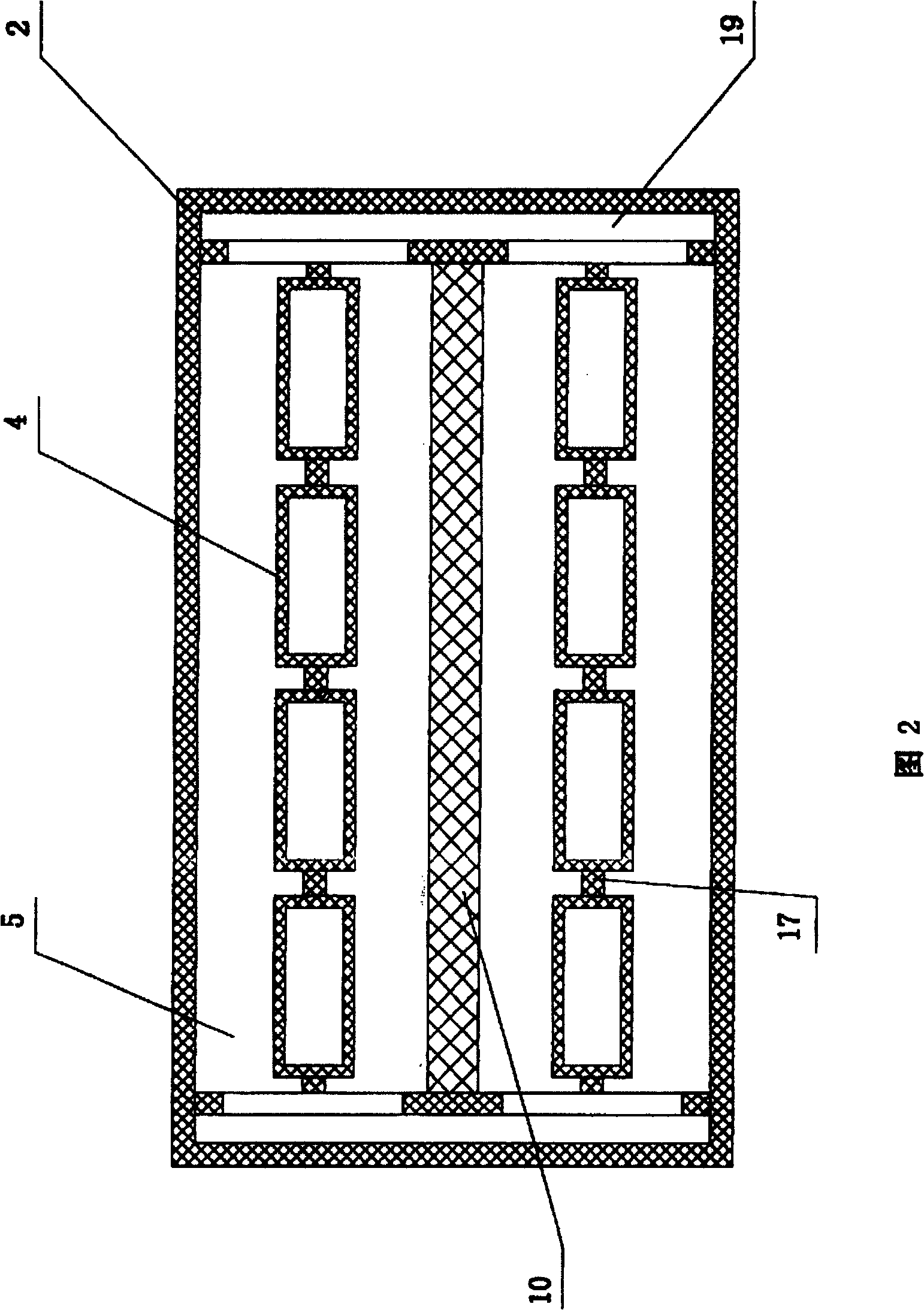

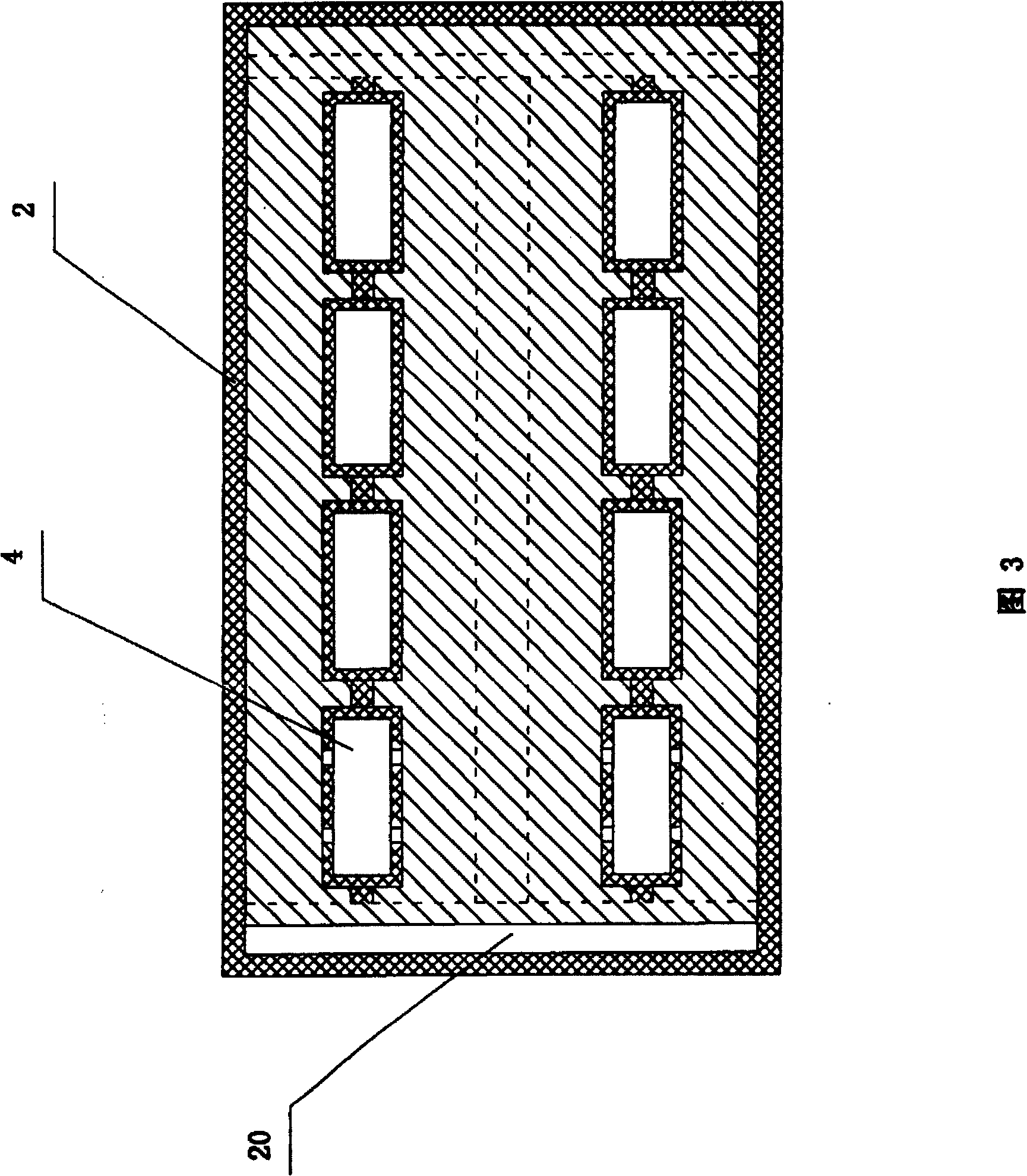

[0018] Embodiment: a specific embodiment of the present invention such as Fig. 1, Fig. 2, Fig. 3, Figure 4 As shown, the furnace has a square furnace body 2, the furnace body has two layers, the inner layer is an insulating layer 2-1, and the outer layer is a brick layer 2-2. Two rows of calcined coal tanks 4 are arranged vertically from top to bottom in the furnace body. , its surroundings are fire passages 5, and there are two groups of calcined coal tanks 4 in parallel, eight in total, with a feeding hopper 1 at the top and a discharge hopper 6 at the bottom, and a vertical partition wall 10 in the middle of the body of furnace 2, for dissolving the calcined coal The tank 4 and the fire channel are divided into two groups on the left and right, and there is a separation wall 17 between each group of calcined coal tanks. From a longitudinal perspective, the fire channel in the furnace body is formed by the staggered distribution of the horizontal partition wall 18 and the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com