Track soundproofing arrangement

A noise control, flat panel technology, applied in tracks, roads, buildings, etc., can solve problems such as damage to the sound-absorbing layer, destruction of the noise reduction effect, and insufficient noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

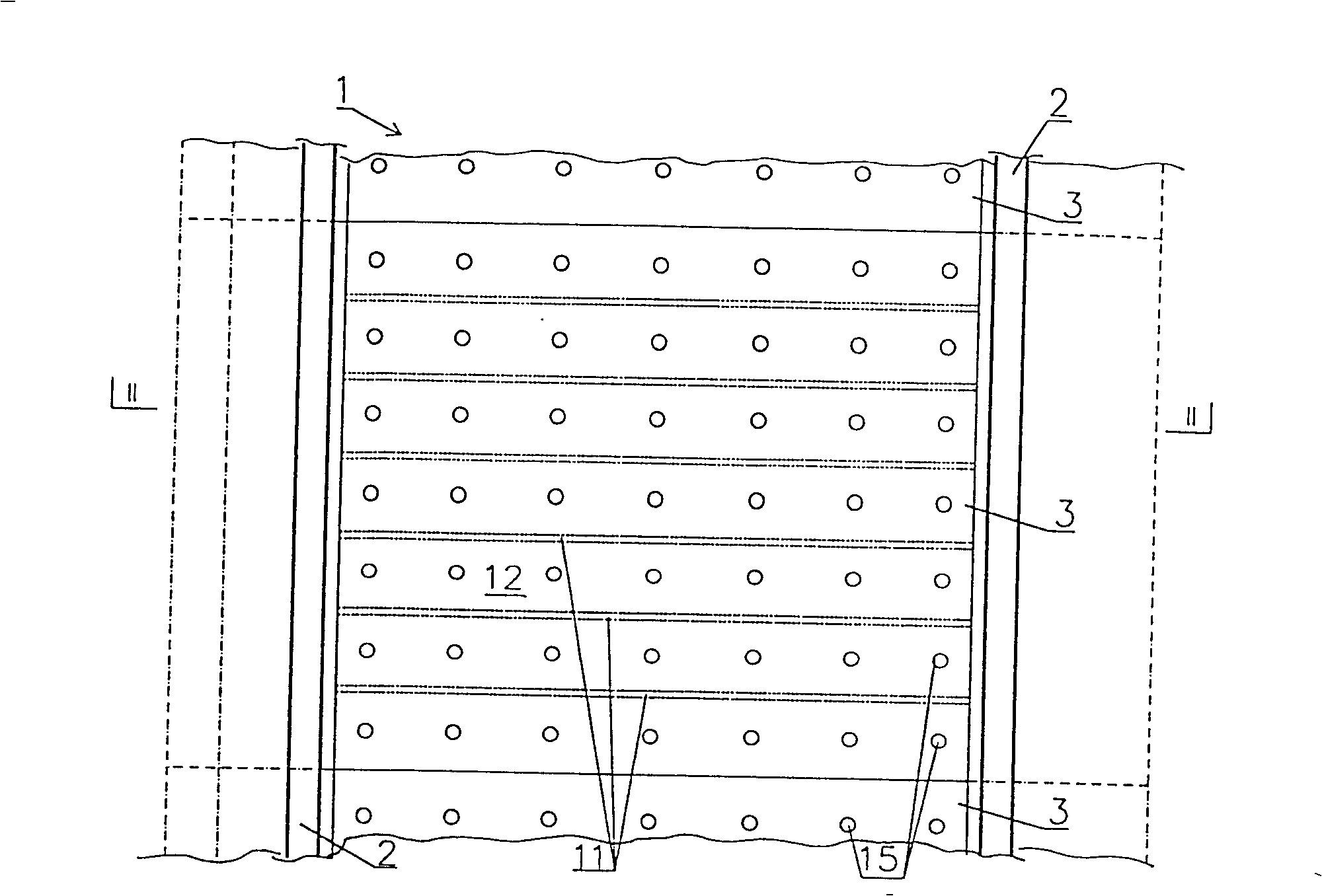

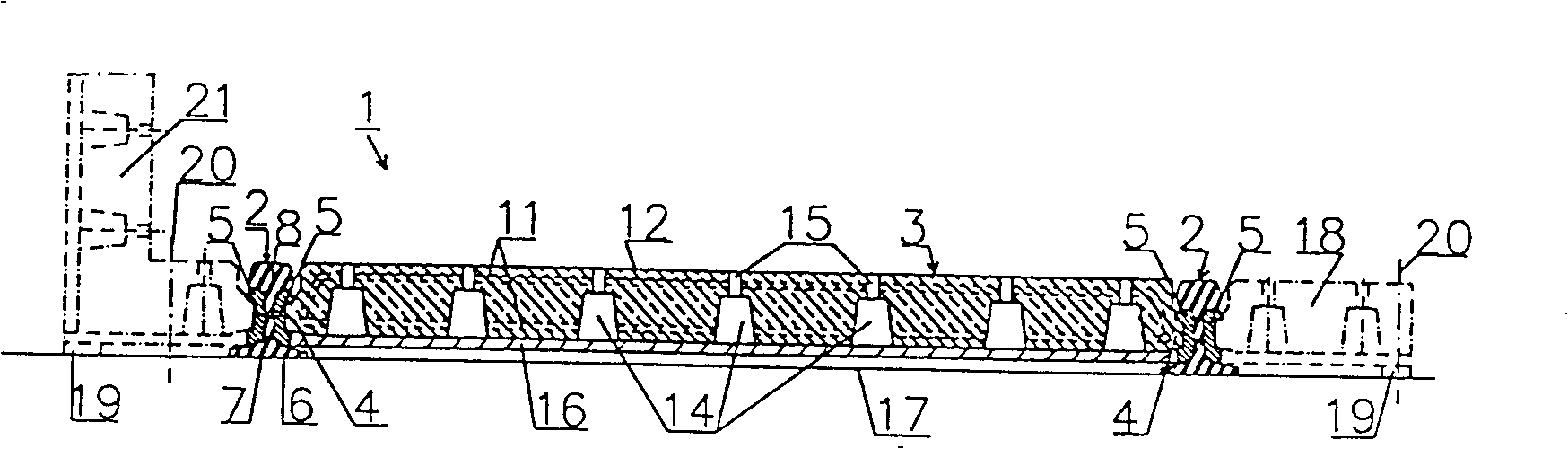

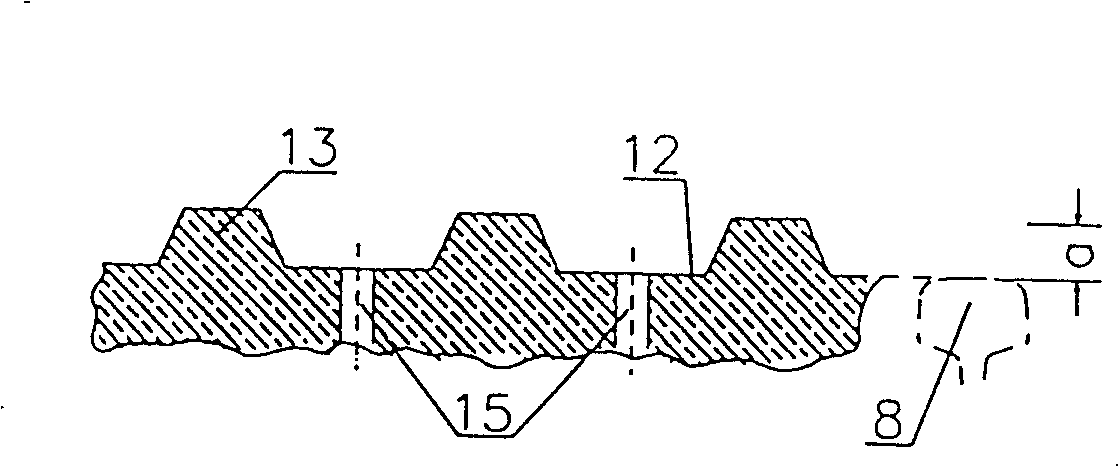

[0037] exist figure 1 and figure 2 In the track 1 shown, the sound-absorbing panels 3 are placed adjacently between the rails along the longitudinal direction of the track. On its two sides extending along the rail 2, the generally rectangular flat plate 3 comprises protruding support flanges 4 which are supported between the undersides of the rail seat 6, the web 7 and the head 8 of the rail 2 , into which is inserted an elastic member 5 made, for example, of rubber or synthetic rubber. The surface of plate 3 is as Figure 4 As shown in the enlarged view of , the plate 3 is composed of porous building material particles 9 bound together by a suitable binder. Such lightweight construction materials may use, for example, synthetic material granules, granular or spherical burnt aluminum granules, natural or man-made burnt materials like granulated slag, which are precisely joined together by a suitable artificial binder or cement, This leaves small gaps or channels 10 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com