Dry small-sized high-voltage metallation organic film capacitor

An organic thin film and metallization technology, applied in the field of dry-type high-voltage filter capacitors, can solve the problems of shell deformation, weight increase, inability to meet the requirements, and achieve the effect of simplified structure, reduced weight, and no oil leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] A kind of specific embodiment of the present invention is:

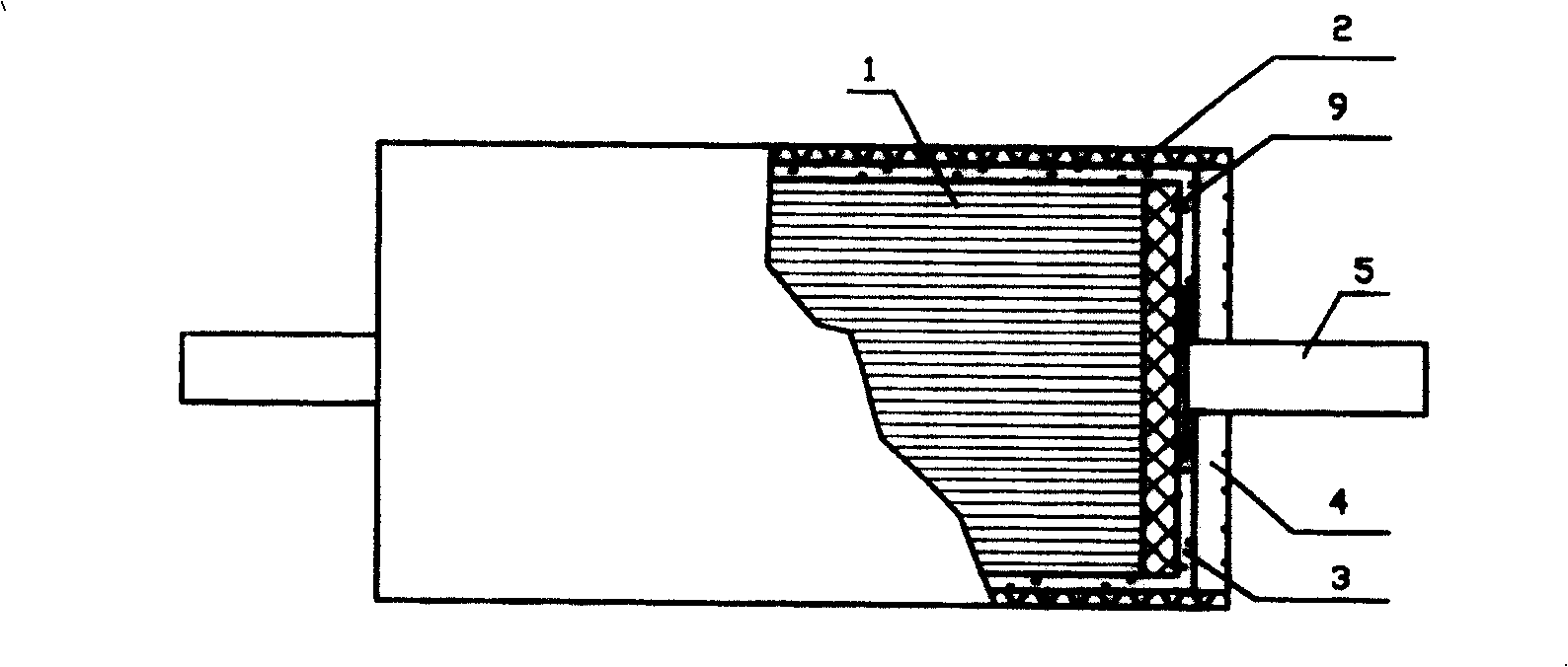

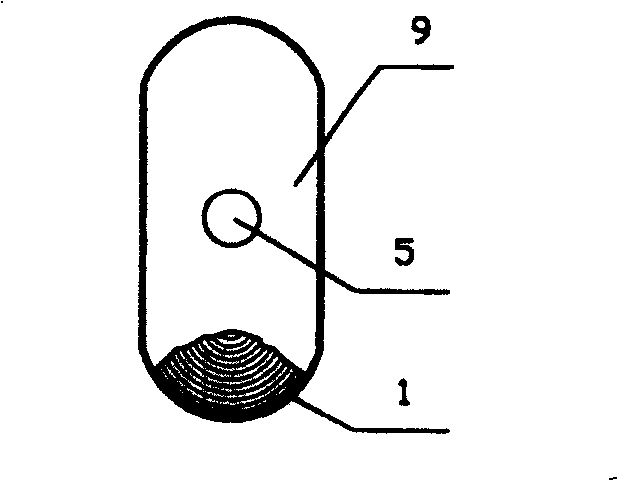

[0016] figure 1 , figure 2 Shown, by core 1, core encapsulation layer 3, in a kind of dry-type small-sized high-voltage metallized organic film capacitor that lead-out 5 constitutes, core encapsulation layer 3 is epoxy resin layer 3, and this epoxy resin The peripheral surface of layer 3 is wrapped with pressure-sensitive tape 2, and the end of epoxy resin layer 3 is perfused with an epoxy resin end perfusion layer 4; the dielectric layer 8 of core 1 is at least two layers of polypropylene film or polyester film .

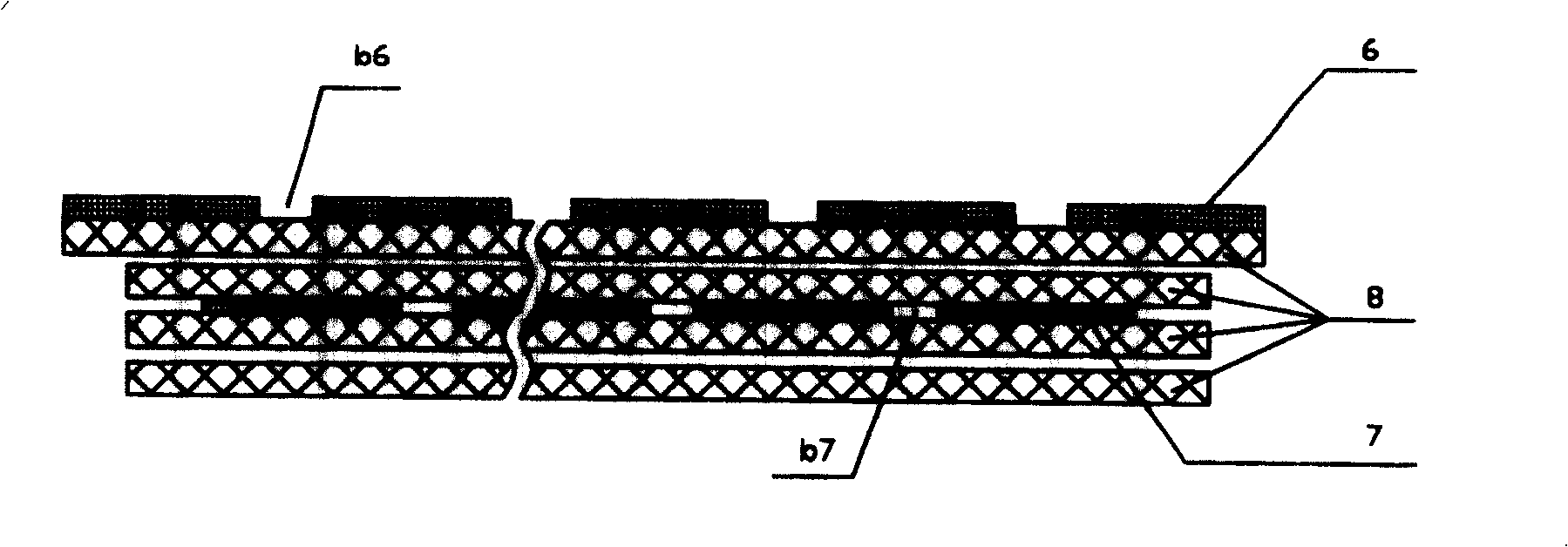

[0017] figure 2 Shown, one side of the dielectric layer 8 of the embodiment of the present invention is distributed with a plurality of mutually interrupted upper electrode strips 6, and the other side of the dielectric layer 8 is distributed with a plurality of mutually interrupted lower electrode strips 7; the upper electrode strips 6 and the lower electrode strips 7 are arranged in a stagg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com