High concentration organic zinc fertilizer and its preparing method

A high-concentration, organic zinc technology, applied in the field of chemical fertilizers, can solve problems such as lack of pertinence, and achieve the effect of strong pertinence, stable performance and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Present embodiment 1 high-concentration organic zinc fertilizer is made of the following raw materials by weight percentage:

[0019] Zinc oxide 52.5

[0020] Triethanolamine 16

[0021] Diethanolamine 4.5

[0022] Alkylphenol ethoxylates 8

[0023] water 19

[0024] After the above raw materials are mixed, they are stirred and reacted at 35°C±5°C for 3 hours, and the mushrooms are pulverized by a machine for 0.5 hours to obtain the product of the present invention. Its fertilizer effect is shown in Table 1.

Embodiment 2

[0026] Present embodiment 2 high-concentration organic zinc fertilizer is made of following raw material by weight percentage:

[0027] Zinc oxide 40

[0028] Zinc chloride 15

[0029] Triethanolamine 10

[0030] Diethylamine tetraacetic acid 4.5

[0031] Sorbitan monooleate polyoxyethylene ether 8

[0032] water 22.5

[0033] After mixing the above raw materials, stir and react at 75±5°C for 2 hours, cool to room temperature, crush the mushrooms for 0.5 hours to obtain the product of the present invention. Its fertilizer effect is shown in Table 1.

Embodiment 3

[0035] Present embodiment 3 high-concentration organic zinc fertilizer is made of following raw material by weight percentage:

[0036] Zinc sulfide 45

[0037] Zinc hydroxide 10

[0038] Glycolamine 12

[0039] Urea 2

[0040] Castor oil polyoxyethylene ether 8

[0041] water 23

[0042] After mixing the above raw materials, stir and react at 90±5°C for 2.5 hours, cool to room temperature, crush the mushrooms for 0.5 hours to obtain the product of the present invention. Its fertilizer effect is shown in Table 1.

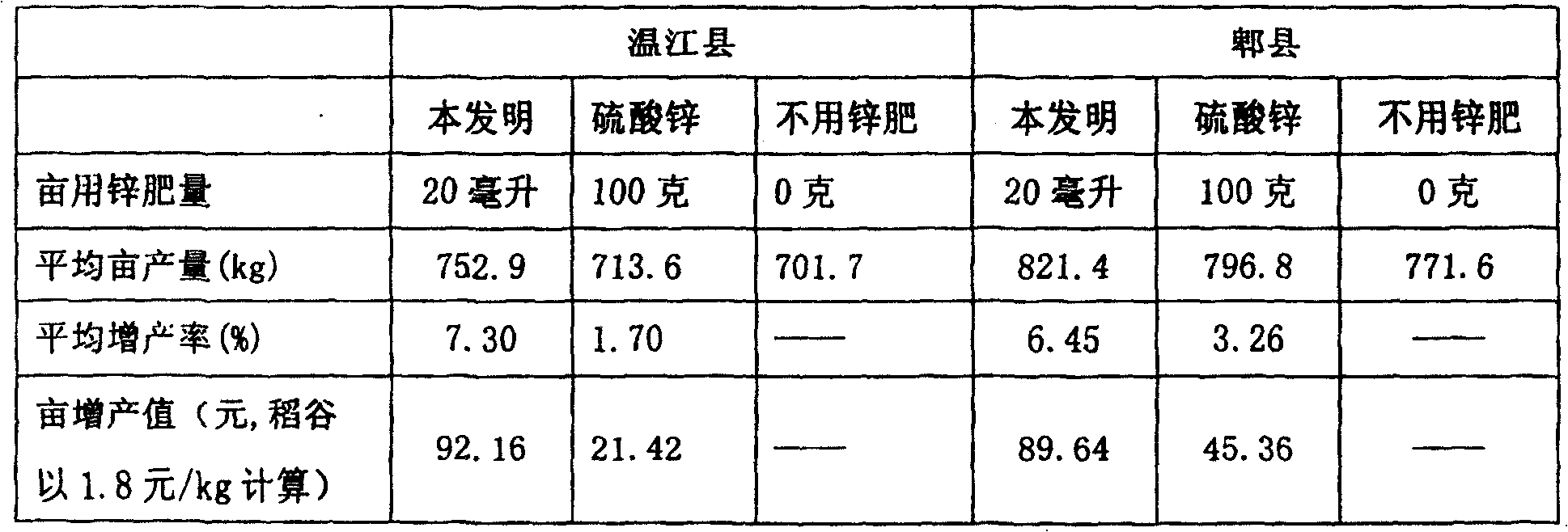

[0043] Table 1 The present invention is used for the test situation of mainly needing zinc crops such as paddy rice

[0044] (This test was carried out in Wenjiang County and Pi County, Sichuan Province)

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com