Ultrathin gate pole oxidation layer and its growing method

A technology of oxide layer and ultra-thin gate, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of difficult to improve the uniformity of gate oxide layer and high leakage current, and achieve the improvement of uneven distribution of electric field, Effects of low leakage current, improved thickness uniformity and hole density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

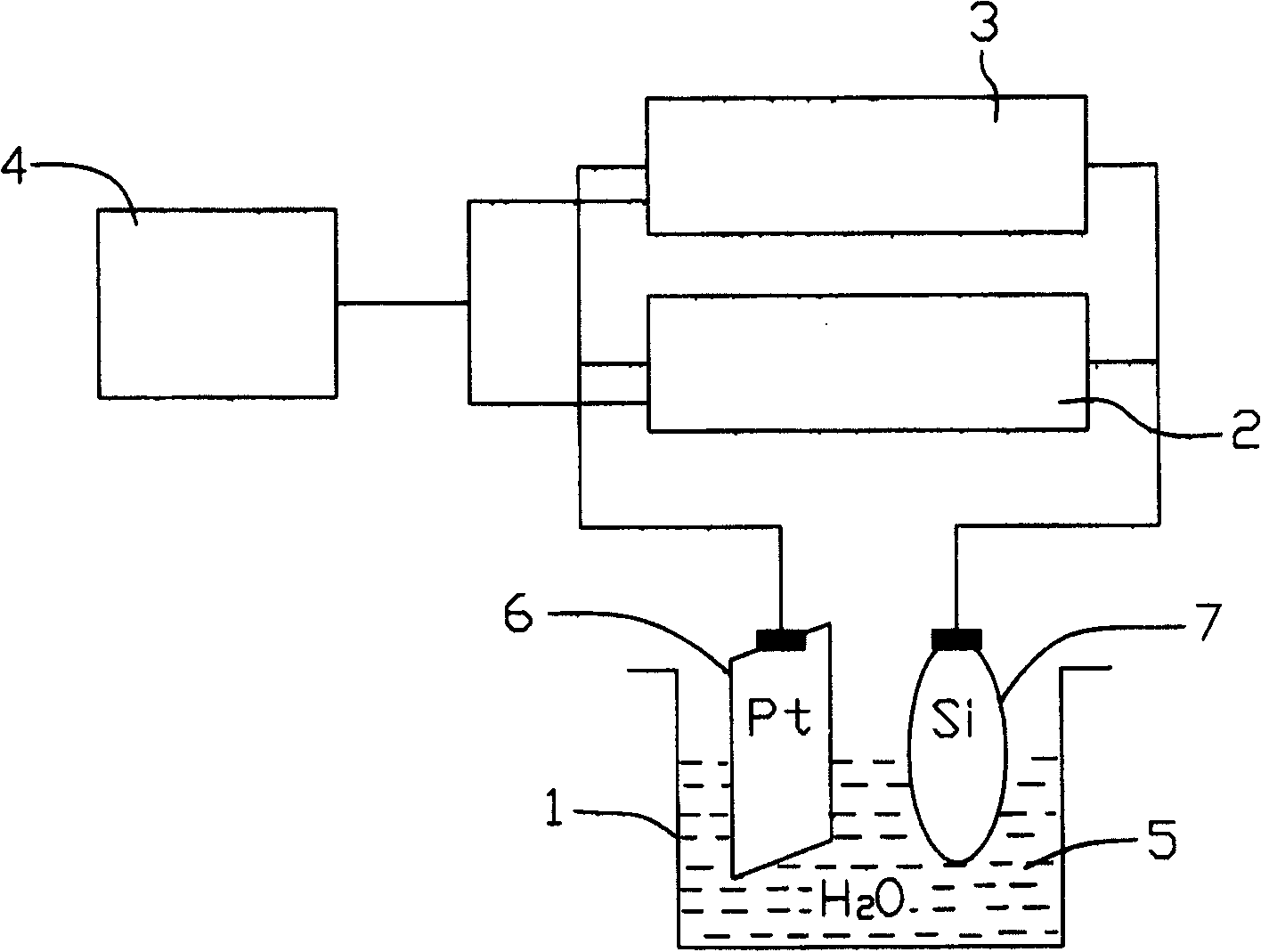

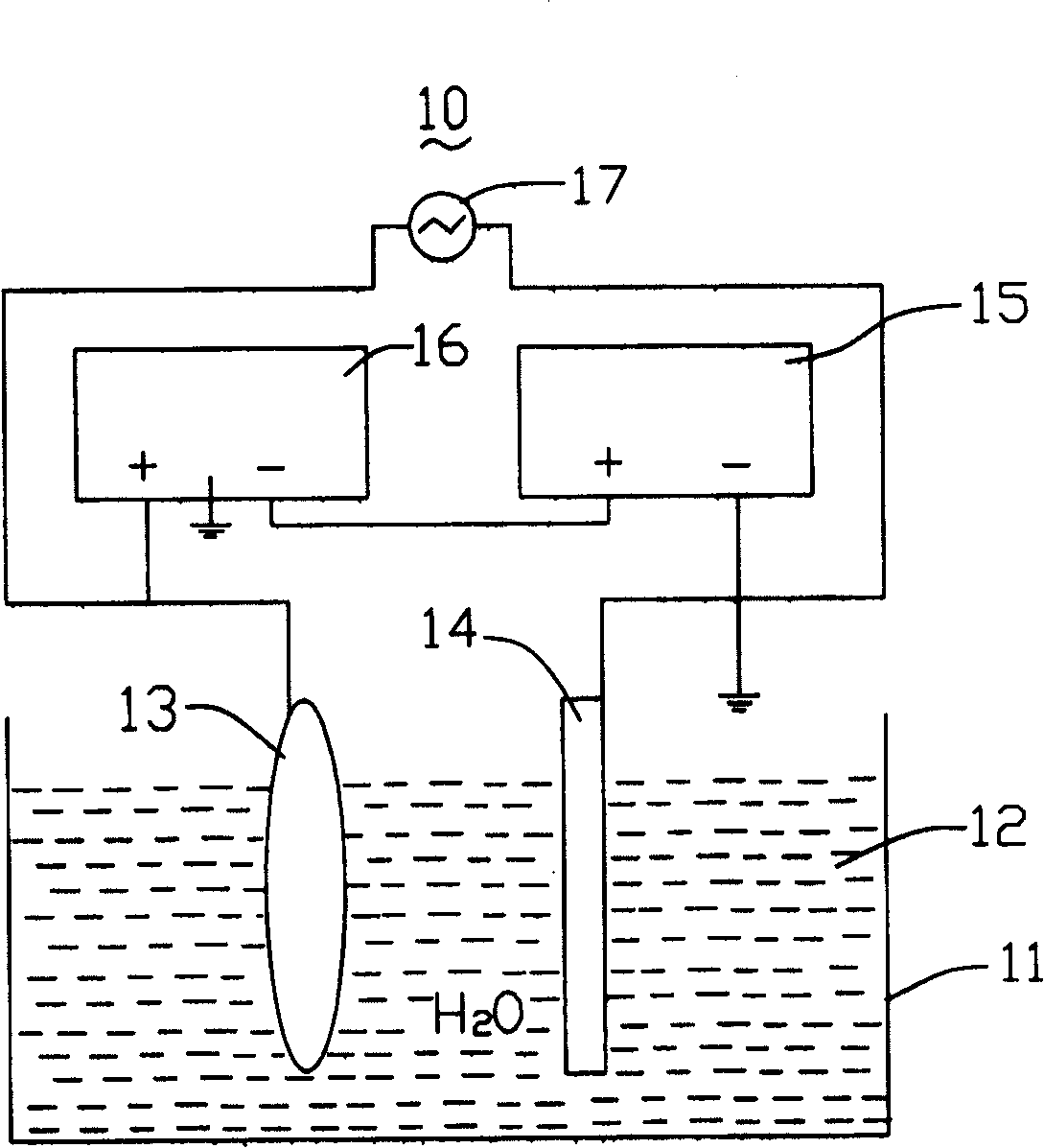

[0021] see figure 2 , is a schematic diagram of the electrolysis system used to grow the ultra-thin gate oxide layer. This electrolysis system 10 comprises an electrolytic cell 11, filled with electrolyte solution 12 in it; An anode 13; A cathode 14; A power supply 15, it can supply the power of the whole system; An electrostatic generator 16, it provides range-adjustable Static voltage, such as 0-60V, which can provide constant voltage or constant current density; and an alternating current generator 17, which provides alternating current with fixed frequency and small amplitude range. Wherein, the electrolyte 12 adopts deionized water or dilute acid. The anode 13 adopts a silicon chip, and it is completely or partially immersed in the electrolyte 12 as required, while the cathode 14 adopts a platinum metal sheet. In the electrolysis system 10, the electrostatic generator 16 and the AC generator 17 can be connected in parallel or in series, and supply power to the electrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com