System and method for active vibration isolation and active vibration cancellation

A technology of mechanical vibration and shock absorber, applied in vibration suppression adjustment, non-rotation vibration suppression, shock absorber, etc., can solve the problem that the exciter and the sensor are not integrated together.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

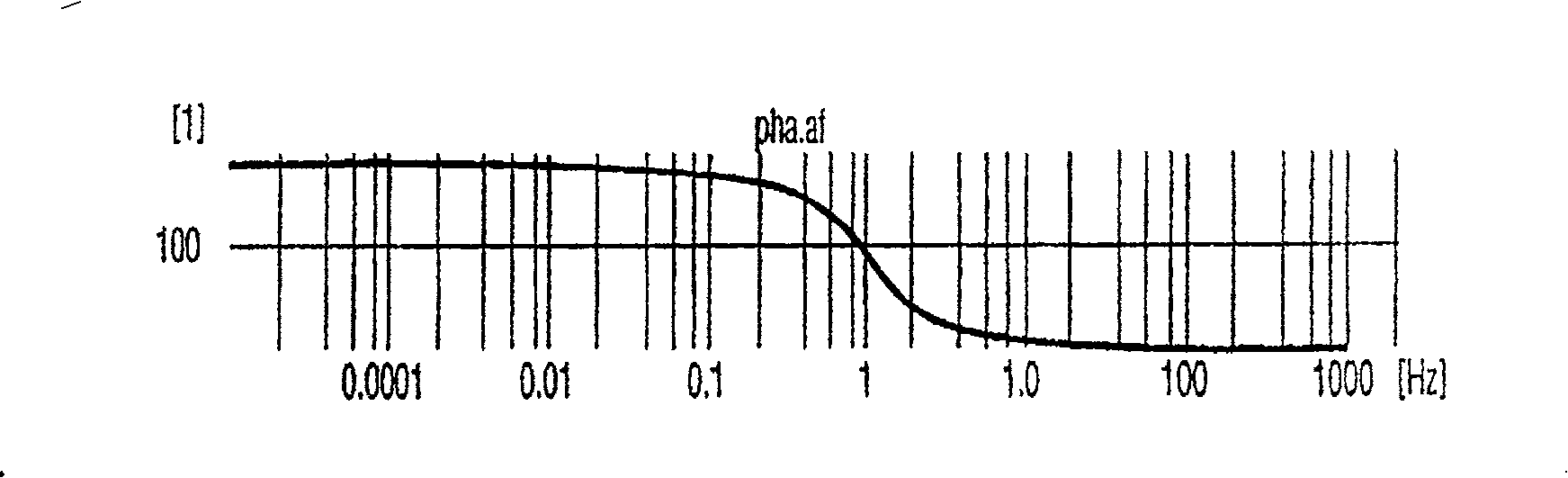

[0038] The limitations of the performance of active isolation / cancellation systems can be described using gain and phase relationships in cybernetics.

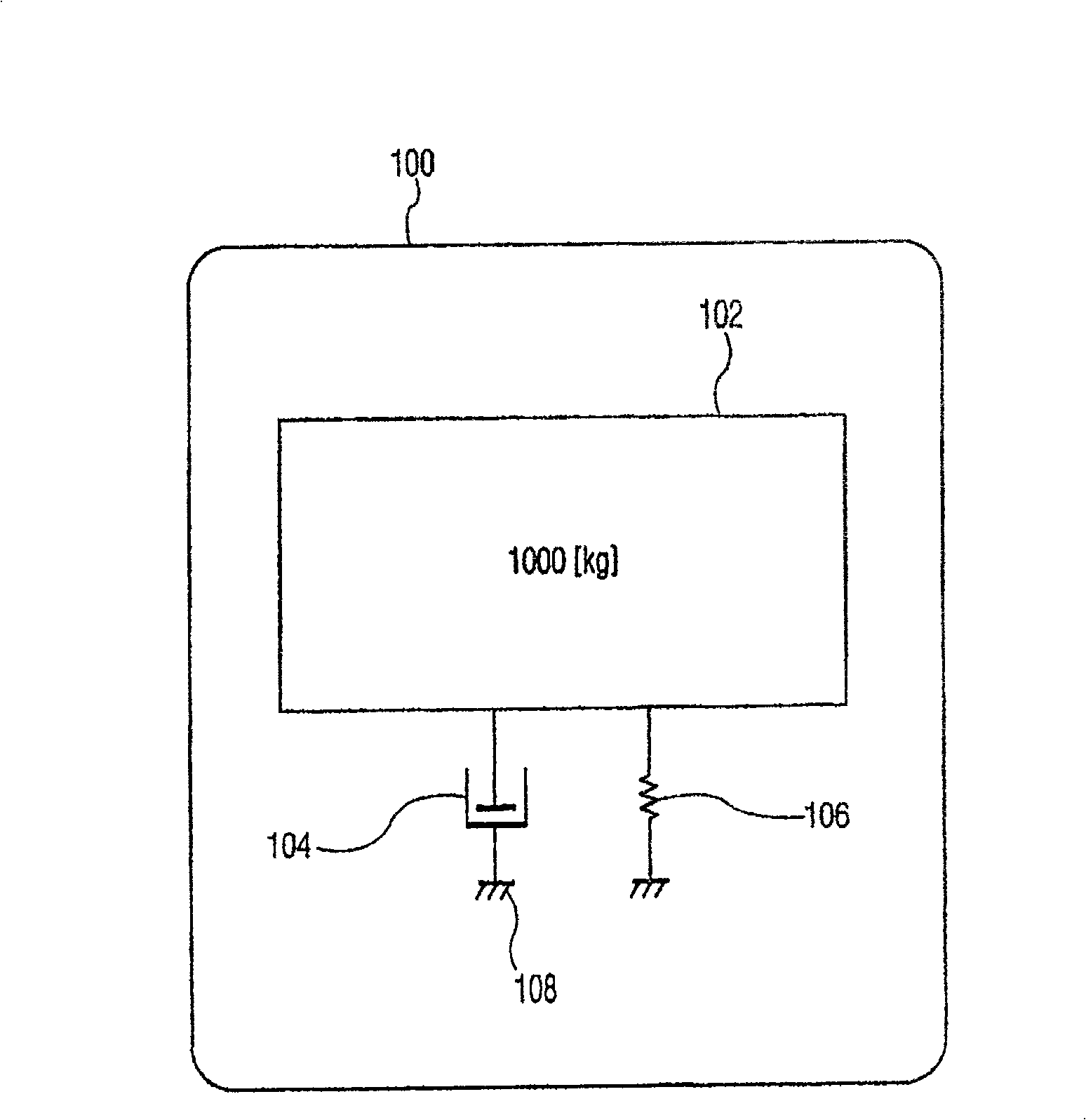

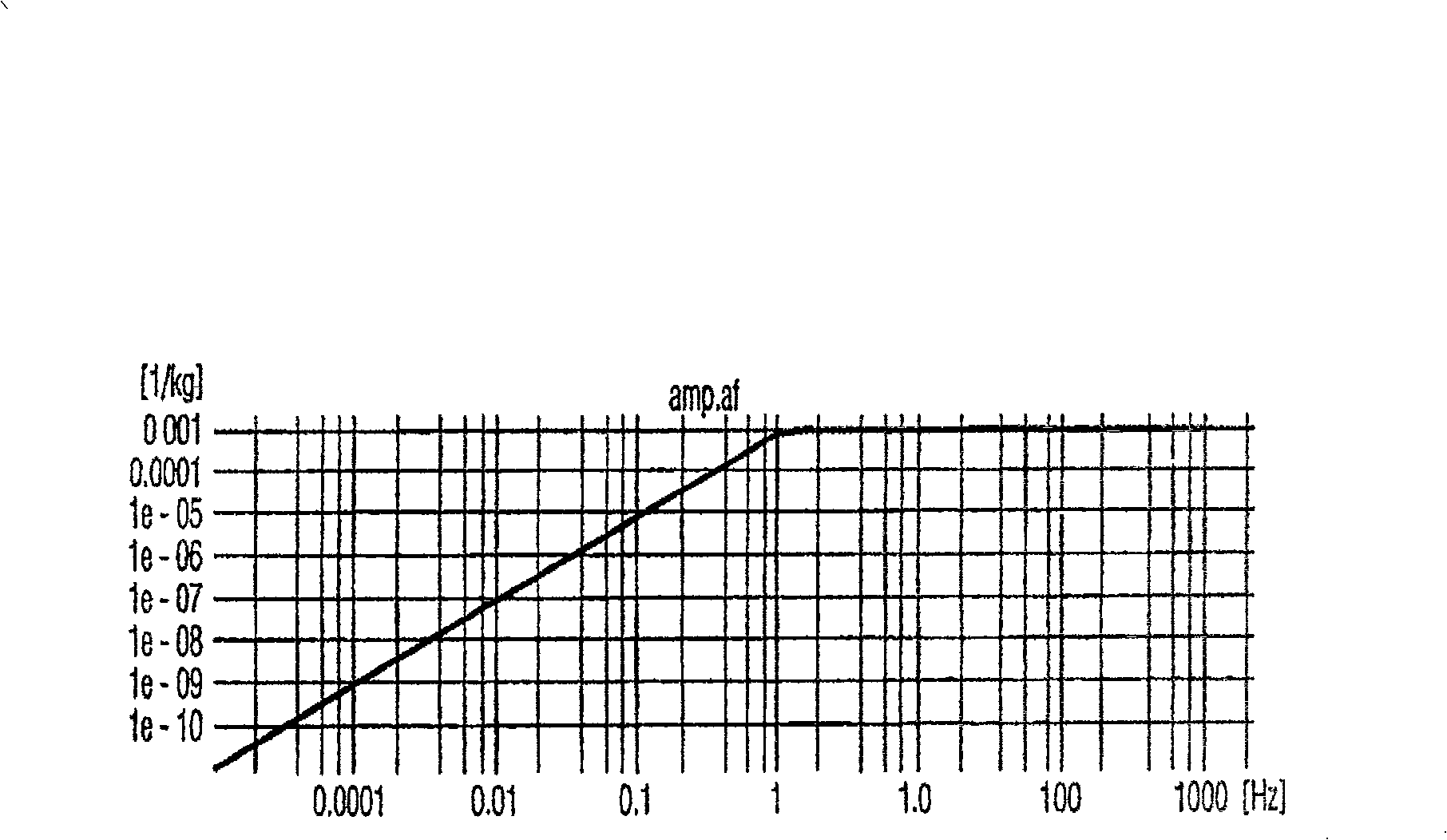

[0039] figure 1 A schematic diagram of a system 100 illustrating the basic vibration damping principles is shown. The schematic 100 includes a main plate 102 of about 1000 [kg], a ground shock absorber 104 , a rigid body (also called a ground spring) 106 and a ground 108 . The main board 102 and the ground 108 are connected to each other through a rigid body 106 and a shock absorber 104 . Rigid body 106 is so stiff that it provides a resonant frequency of 1 Hz. The value of the damper 104 is generally such that the overall system 100 is marginally damped. The force sensitivity of such a system is shown in FIG. 2 .

[0040] In low frequencies, a force of 1 [N] will give a vibration of less than 1 [mm / s2]. When greater than 1[Hz], the vibration amplitude will be a constant 1[mm / s2]. Judging from the products currently on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com