A filter tank

A filter tank and filter chamber technology, applied in the field of water treatment, can solve the problem of not having bubble size segmentation, and achieve the effect of ensuring the effect of backwashing, uniform distribution, and improving the effect of backwashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

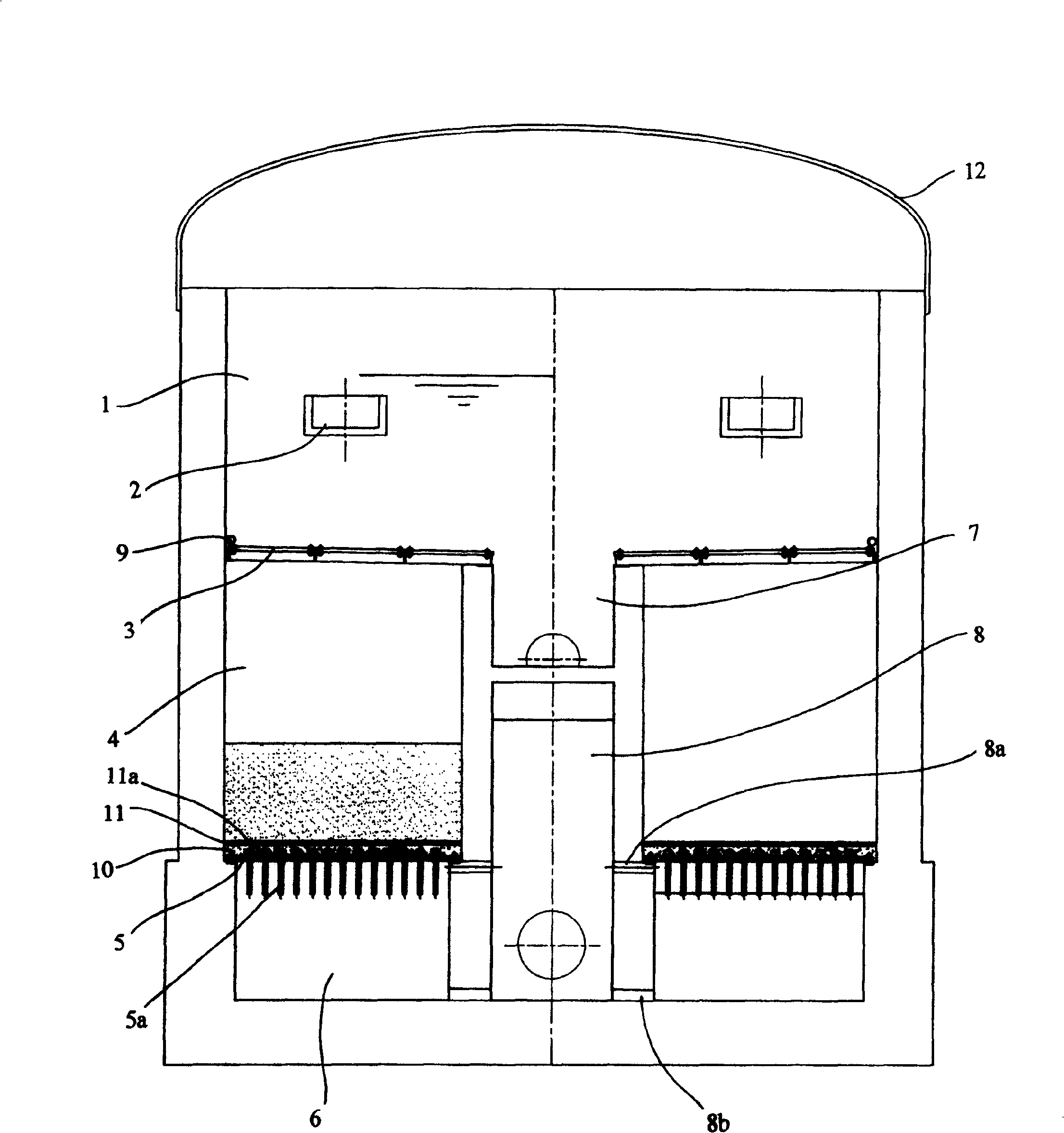

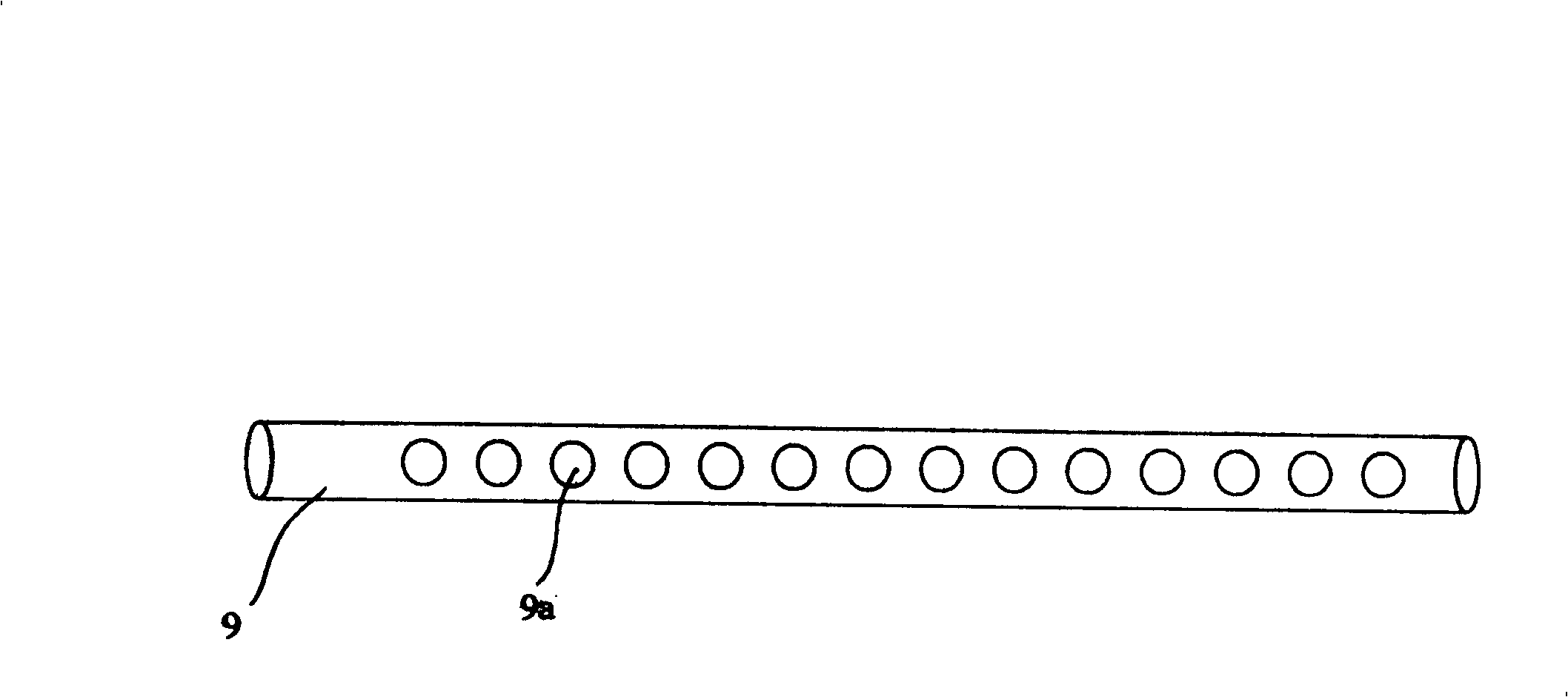

[0018] Such as figure 1 and figure 2 As shown, the filter tank includes two symmetrically arranged filter chambers 1 separated by double-layer intermediate channels arranged on upper and lower layers, a water inlet tank 2 above the filter chamber 1, and a sunshade covering the filter chamber 1. 12. The filter chamber 1 includes filter material blocking device 3, filter layer 4, filter material supporting device 5 and air-water chamber 6 from top to bottom. The double-layer middle channel is the backwash water distribution device, and the upper layer is the The backwash drainage tank 7 adjacent to the filter material device 3, the lower floor is an air-water distribution channel 8 connected with the air-water chamber 6, and an air distribution hole 8a is arranged on both sides of the middle part of the air-water distribution channel 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com