External set type ultrasonic fluid treatment device

A fluid processing and ultrasonic technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as increasing fluid resistance, inability to install ultrasonic transducers inside pipelines, and unfavorable fluid transportation, etc. Achieve the effect of meeting the requirements of pipe wall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

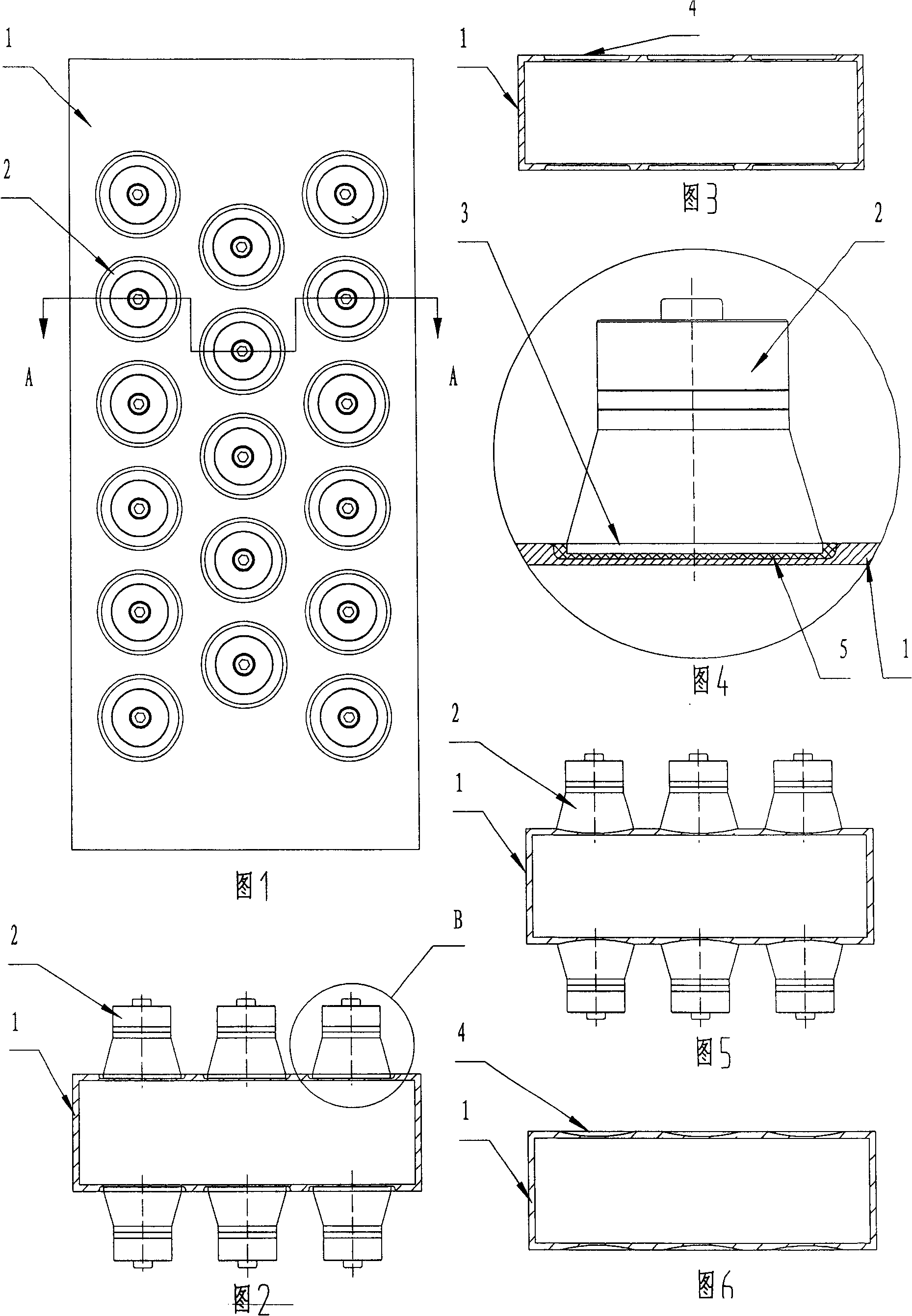

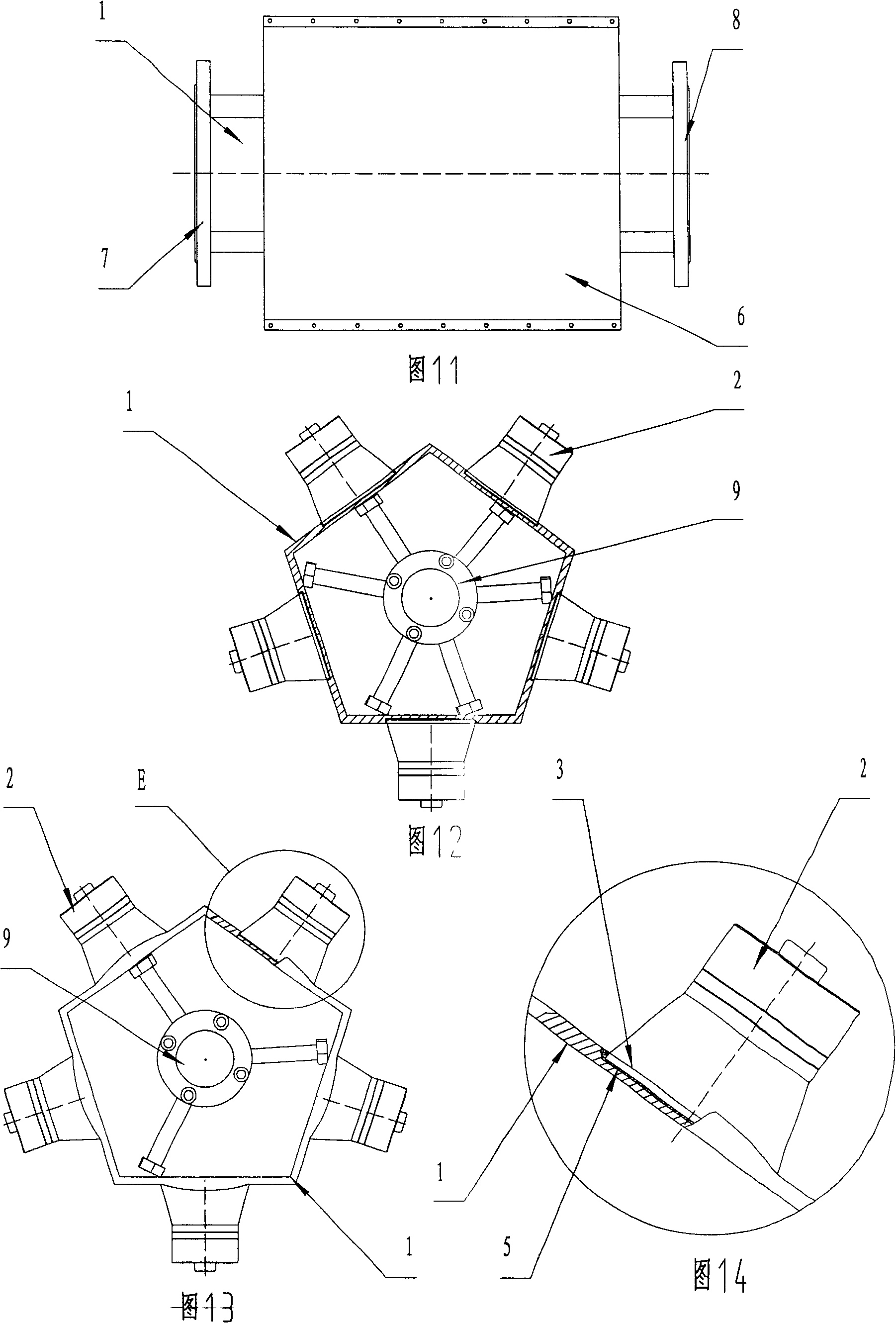

[0032] Embodiment 1: As shown in Figures 1 to 4, the ultrasonic fluid treatment device in this embodiment has an outer tube 1 and an ultrasonic transducer 2, the ultrasonic transducer 2 is arranged outside the outer tube 1, and the ultrasonic transducer The energy device has an ultrasonic transmitting end 3, and the ultrasonic transmitting direction of the ultrasonic transmitting end 3 is toward the inside of the outer tube 1, and is characterized in that an insertable cavity recessed toward the inner cavity of the outer tube is provided on the outer wall of the outer tube 1. The tube wall concave portion 4 of the ultrasonic transmitting end, the ultrasonic transmitting end 3 is inserted into the tube wall concave portion 4, and an adhesive is provided between the tube wall concave portion 4 and the ultrasonic transmitting end 3 Adhesive layer 5, the adhesive layer 5 bonds and fixes the tube wall concave portion 4 and the ultrasonic emitting end 3 as a whole, and makes the end ...

Embodiment 2

[0034] Embodiment 2: As shown in Figures 5 and 6, the ultrasonic fluid treatment device in this embodiment is similar to that in Embodiment 1, except that the shape of the outer tube 1 in this embodiment is slightly changed.

Embodiment 3

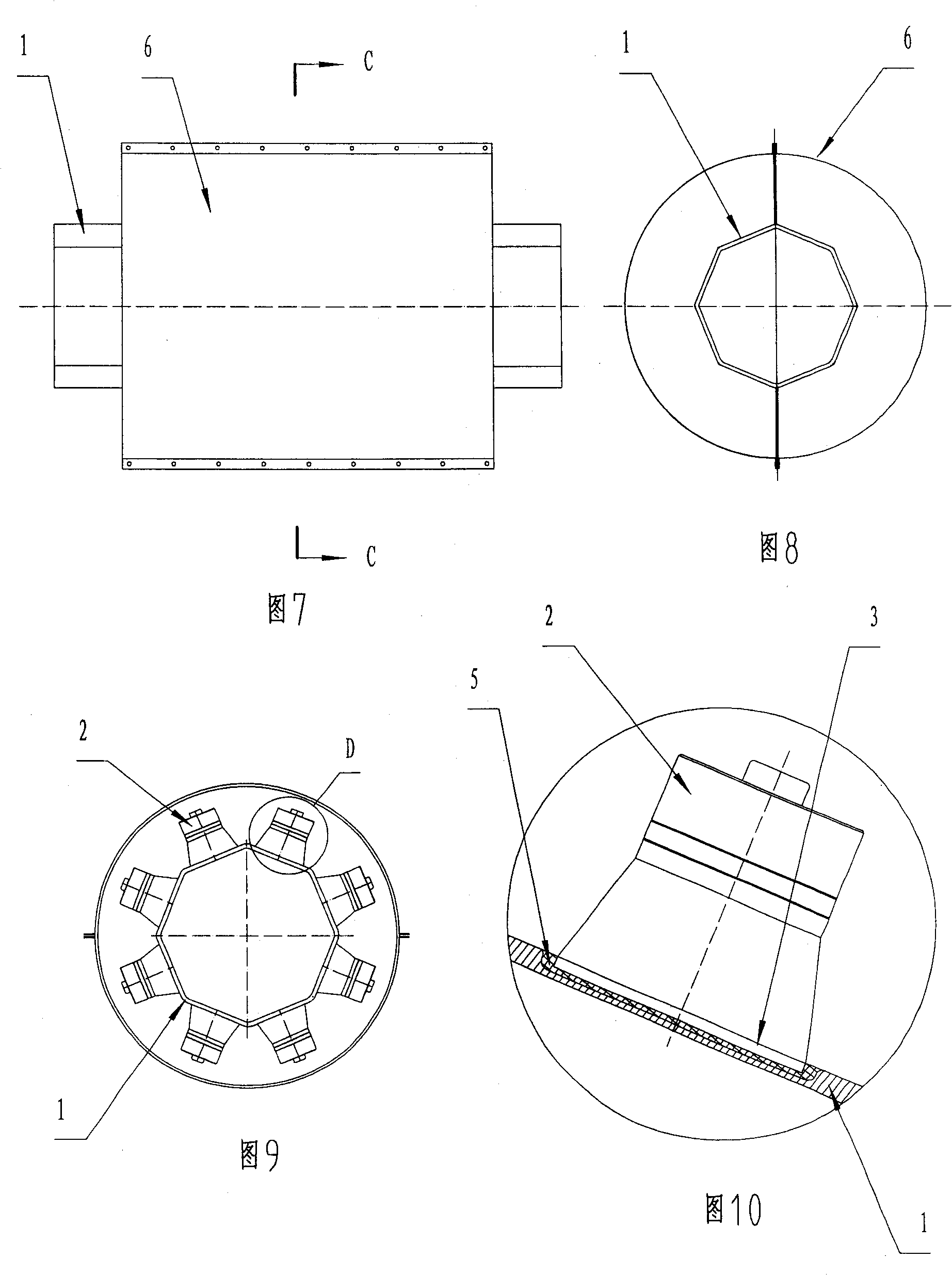

[0035] Embodiment 3: As shown in Figures 7-10, the ultrasonic fluid treatment device in this embodiment is similar to Embodiment 1, the difference is that in this embodiment, the shape of the inner cavity cross-section of the outer tube 1 is positive 8 polygon. In addition, the product of the first embodiment is provided with an outer cover 6, and the outer cover 6 completely covers the ultrasonic transducer 2 and the two ends of the outer tube 1 arranged outside the outer tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com