Container manufacturing device

一种容器制造、容器主体的技术,应用在容器制造装置领域,能够解决难以判断针尖、难以控制针尖温度等问题,达到防止故障的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

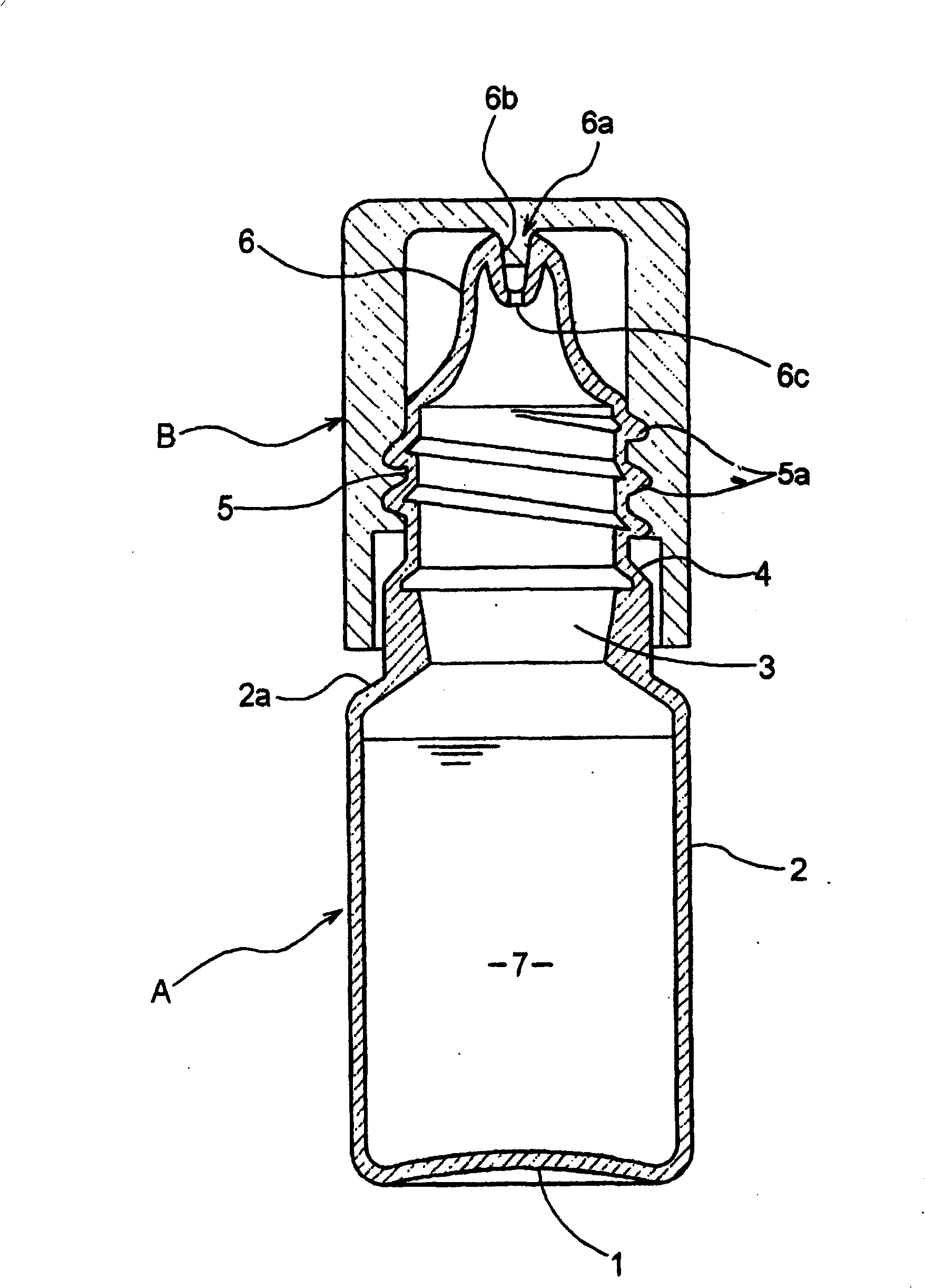

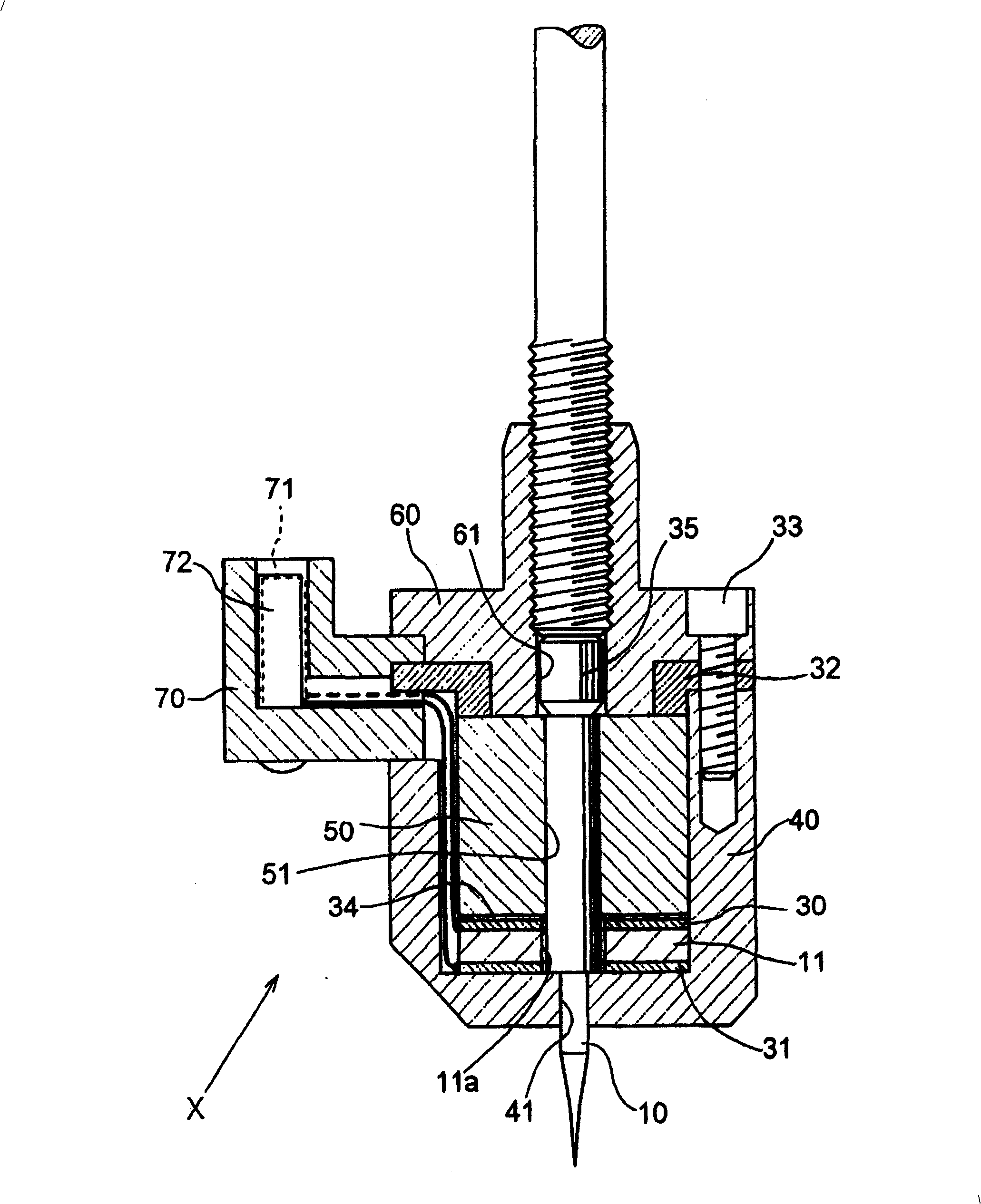

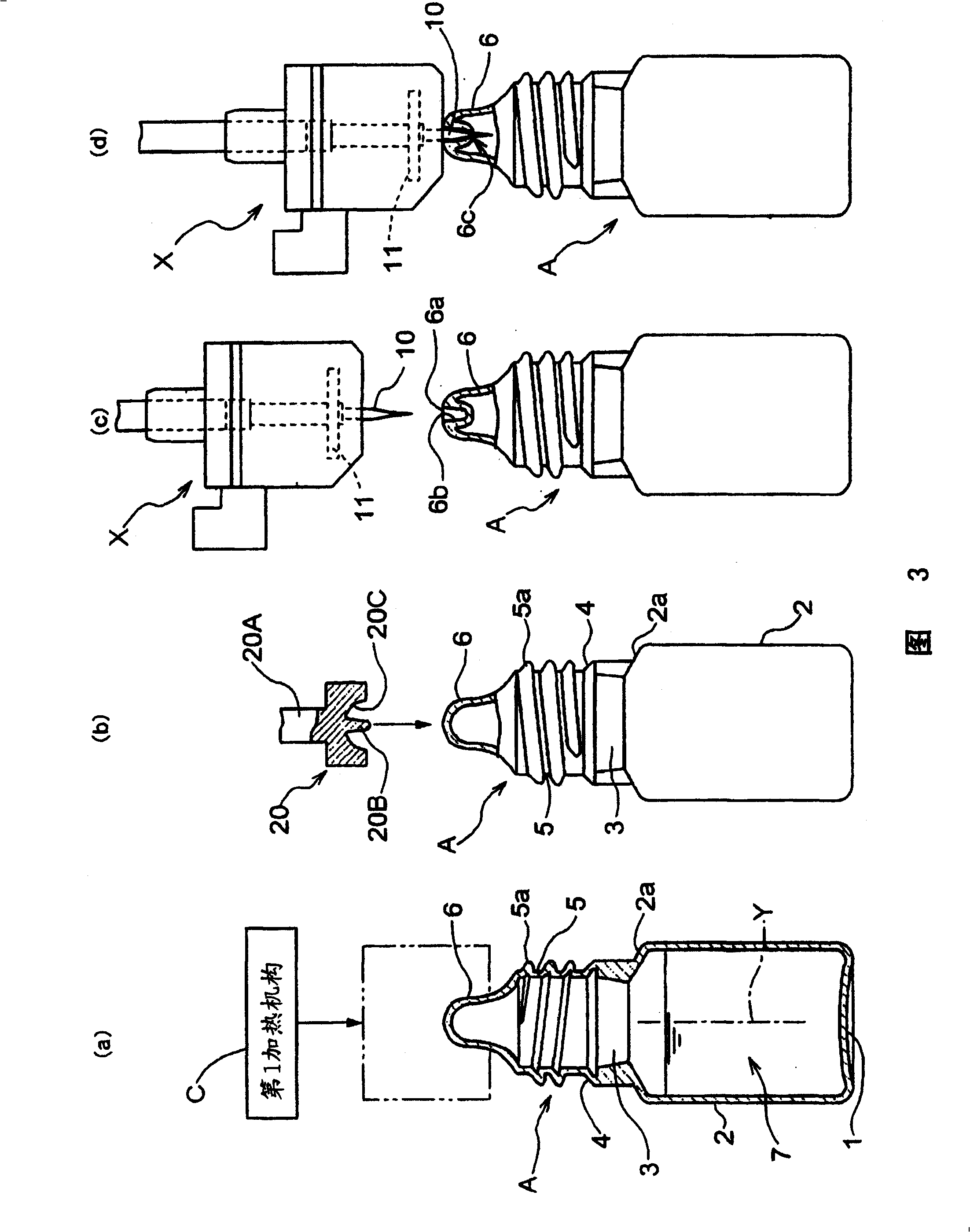

[0068] Next, the process of forming the liquid injection hole 6c in the above-mentioned eye infusion container using the container manufacturing apparatus of the present invention will be described (see FIG. 3 ).

[0069] The thermoplastic material used as the constituent material of the container main body A includes polyethylene, polyethylene-polypropylene, polypropylene, polyethylene terephthalate, polycarbonate, and the like. In this example, the container main body A formed of polyethylene is shown.

[0070] In the container body manufacturing section described above, the container body A is manufactured by blow molding or vacuum molding. Blow molding or vacuum forming can be performed by common methods. In addition, the molded container body A is transported to the molding unit by the transport supply unit.

[0071] In the molding section, the liquid injection port 6a is molded on the container main body A using a liquid injection port forming mechanism (refer to figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com