Light guiding plate mould and its preparation method

A light guide plate and mold technology, which is applied in optics, optical components, household appliances, etc., can solve the problems of insufficient diversification and miniaturization of microstructures, unfavorable thinning of display devices, and complex structure of backlight modules, etc., and achieves a variety of grooves. optimization, low cost, and simplification of the effect of the backlight module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

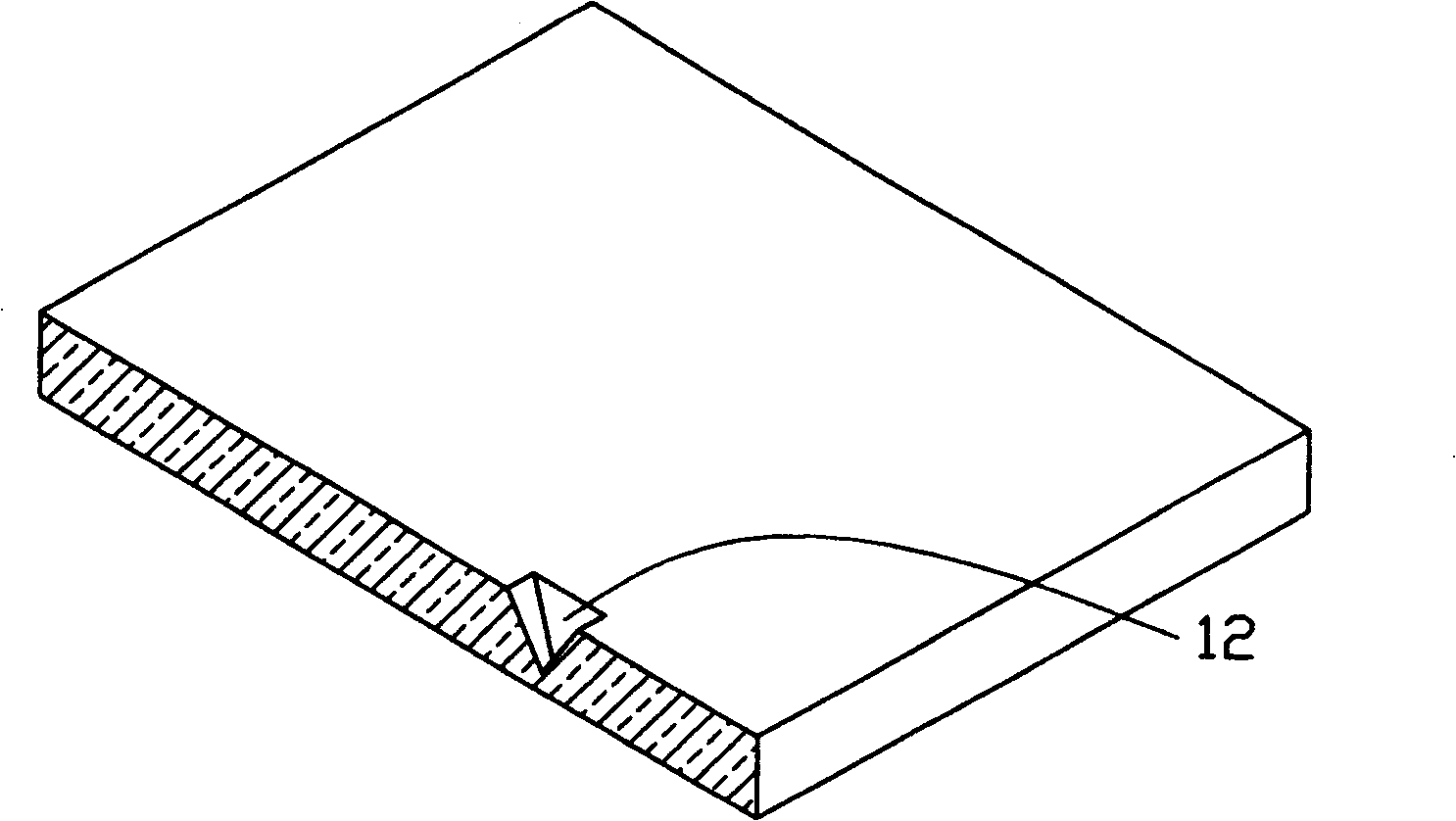

[0027] The light guide plate mold provided by the present invention and its preparation method are illustrated below in conjunction with the accompanying drawings:

[0028] see Figure 11 , the light guide plate mold preparation method provided by the present invention comprises the following steps:

[0029] Step 10, provide an embossing machine with a plurality of indenters of different shapes; the indenters are generally made of diamond and other hard and wear-resistant materials through fine processing, and have a long service life.

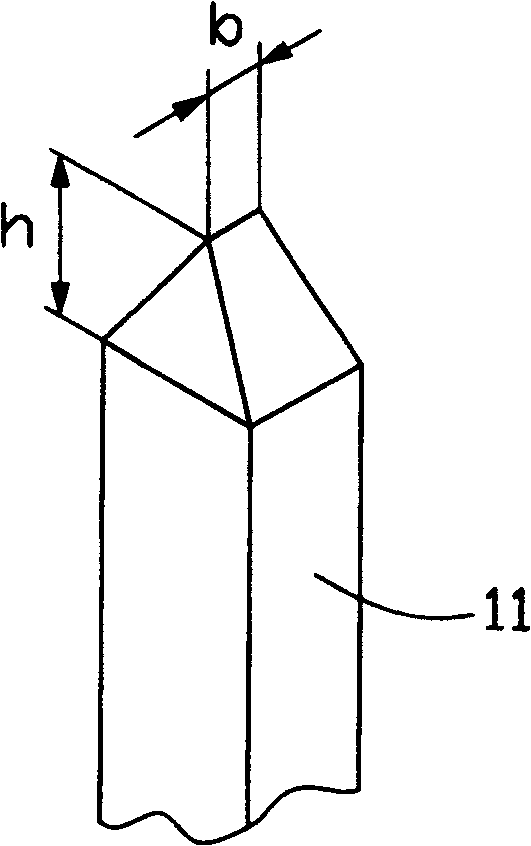

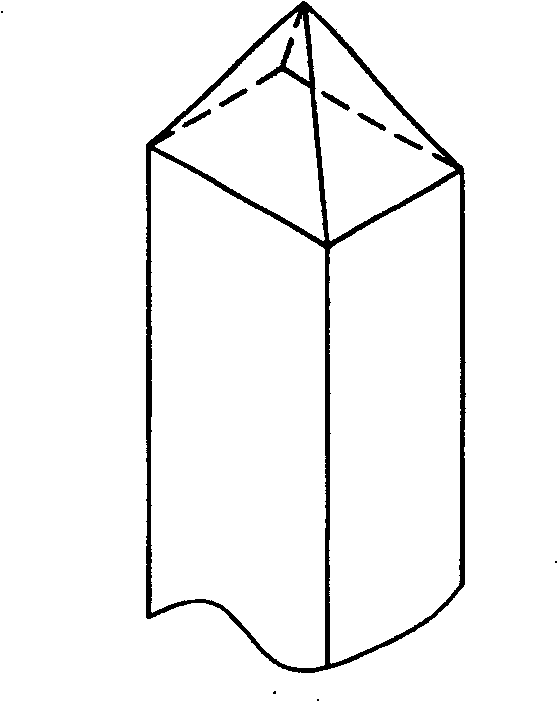

[0030] The indenter has such figure 1 , image 3 , Figure 4 , Figure 5 The different pyramid or conical shapes shown may also have other shapes such as spherical or prism, which can be freely designed according to optical design requirements, and are not limited to cone, sphere or cylinder. The conical indenter can emboss a groove with a V-shaped axial section and a triangular, square or circular groove in the radial section. The cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com