Polyacrylonitrile-based carbon fiber precursor oiling method and device

A technology of polyacrylonitrile-based carbon fiber and raw silk, which is applied in the processing of textile material equipment configuration, liquid/gas/vapor yarn/filament processing, textile and papermaking, etc. Stability and other issues, to achieve the effect of improving uniform stability, uniform oiling, and increasing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

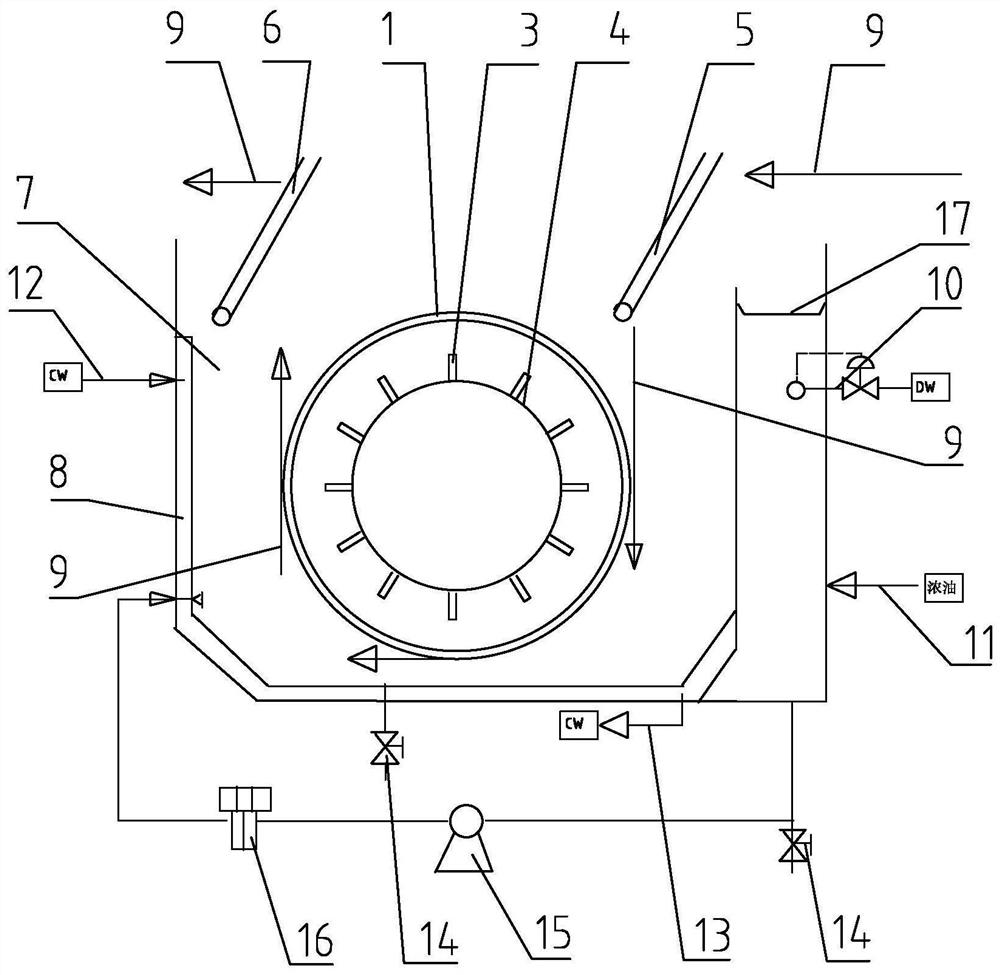

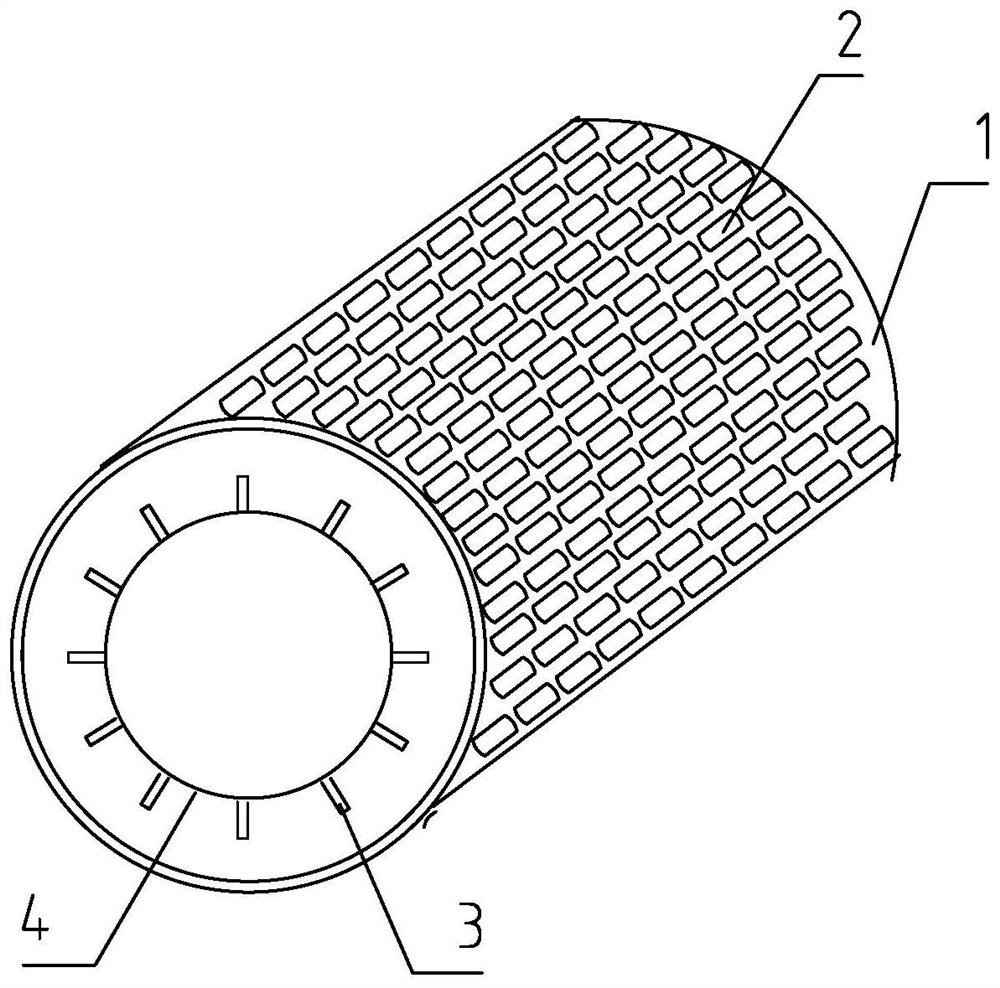

[0029] Such as Figure 1-3 As shown, an oiling device for polyacrylonitrile-based carbon fiber precursors includes an oiling roller 1, a polygonal roller 4, a transmission roller, an oiling bath 7, an oiling circulation system, a desalinated water replenishing system 10, and a thick oil replenishing system. Add system 11, the surface of oiling roller 1 is provided with mesh 2, the spraying force of oil agent will be reduced if mesh 2 is too large, and the oil agent immersed in polygonal roller 4 will be reduced if mesh 2 is too small, single mesh in this embodiment The length of the hole 2 is 15mm, the width is 7mm, and the gap between two adjacent mesh holes 2 is 3mm, so that the area of the mesh hole 2 can not only meet the needs of soaking the polygonal roller 4, but also have enough spray force to ensure that the oil The full contact between the agent and the tow 9.

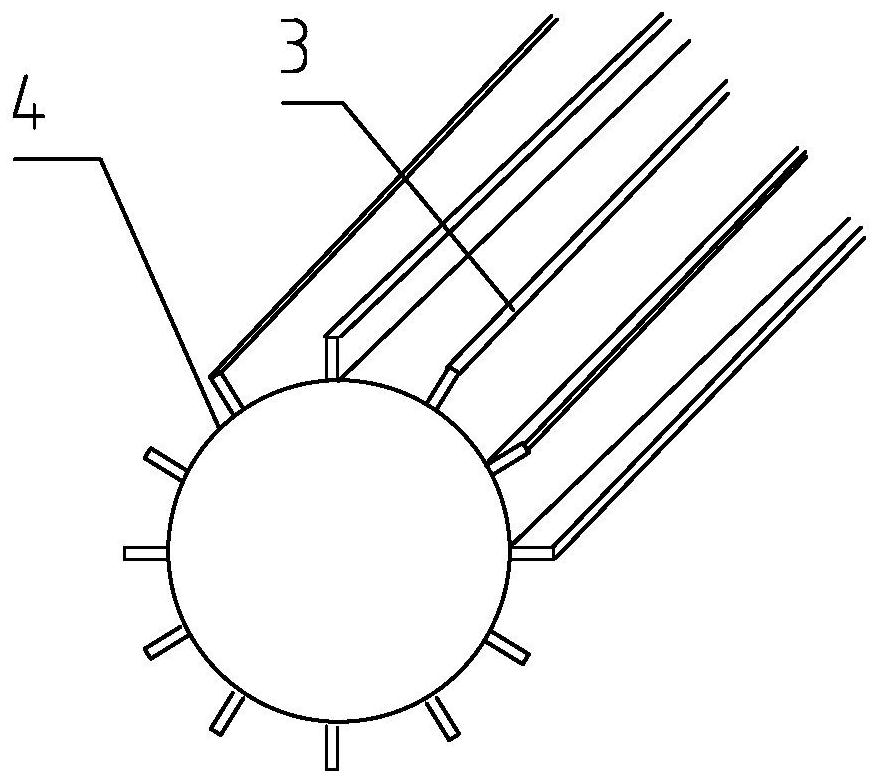

[0030] The surface of the polygonal roller 4 is provided with 12 convex ribs 3, and the inside of the o...

Embodiment 2

[0042] Produced under the same conditions as Example 1, adjust the number of revolutions of the polygonal roller 4 to 25 rpm, continuously detect the oil concentration in 4 directions in the oiling bath 7 for 30 times, and calculate the CV value of the oil concentration to be 1.0%; track 300 Precursor silk sample, detect the oil content of precursor silk tow 9, calculate and obtain the CV value of oil content of tow 9 to be 3.0%.

Embodiment 3

[0044] Produced under the same conditions as Example 1, the number of revolutions of the polygonal roller 4 was adjusted to 75 revs / min, and the oil concentration in 4 directions in the oiling bath 7 was detected continuously for 30 times, and the calculated oil concentration CV value was 0.6%; tracking 300 Precursor silk sample, detect the oil content of precursor silk tow 9, calculate and obtain the oil content CV value of tow 9 to be 2.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com