Cold air spreading and airing machine

A drying machine and cold air technology, applied in the direction of coolers, conveyors, conveyor objects, etc., can solve the problems of low drying efficiency and single function of the drying machine, so as to improve heat exchange efficiency and drying efficiency, and ensure Air quality, the effect of solving the slipping phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

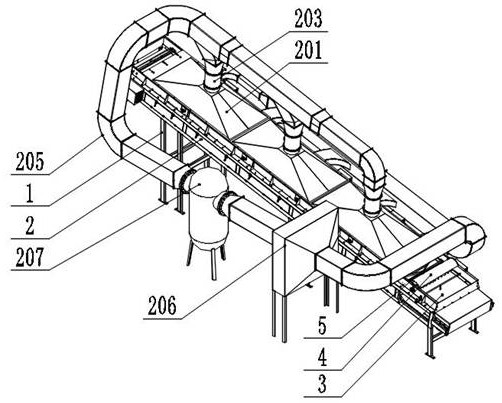

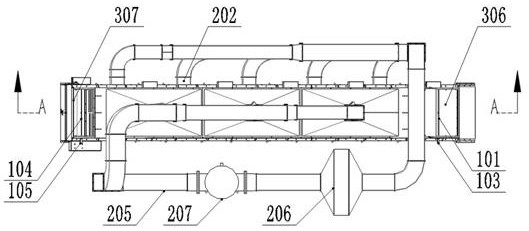

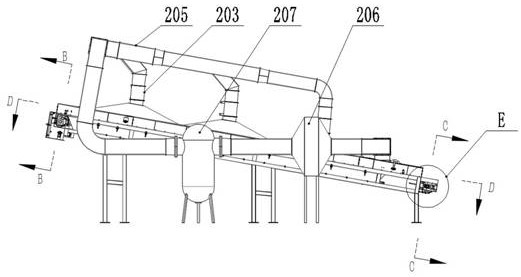

[0070] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 14 , the cold air drying machine of the present invention includes a frame 1, and a chain plate conveyor 3 is arranged on the frame 1; The chain 303 between the driven sprockets 302, the chain plate 304 arranged on the chain 303, and the first reduction motor 305 that drives the driving sprocket 301 to rotate; the chain plate 304 includes the upper transport section 3041 and the lower return section 3042, The two ends of the chain plate conveyor 3 are respectively provided with a feed port 306 and a discharge port 307, the chain plate 304 is provided with ventilation holes (not shown in the figure), and the frame 1 is provided with four air chambers 2, which are used for transportation. The section 3041 is arranged in the air chamber 2, the return section 3042 is arranged outside the air chamber 2, and the air inlet duct 202 is arranged on the side of the air chamber 2 under the transport section 3041;...

Embodiment 2

[0080] refer to figure 1 , On the basis of Embodiment 1, this embodiment is provided with a discharging mechanism 4 on the feeding port. Since the glutinous rice grains are poured into the chain conveyor above the feed port, the glutinous rice grains that have fallen are piled up, that is, the middle is thick and the edges are thin. For this reason, the present invention discharges the thick grains located in the middle of the chain plate to both sides of the chain plate by arranging the discharge mechanism.

[0081] refer to Figure 9 , the discharge mechanism 4 of this embodiment includes a discharge shaft 401 arranged in the width direction of the chain conveyor 3 and a second reduction motor 402 that drives the discharge shaft 401 to rotate. The discharge shaft 401 is provided with a spiral discharge material leaves. The second reduction motor drives the discharge shaft to rotate, and the discharge shaft drives the discharge blades on it to rotate to discharge the thick...

Embodiment 3

[0084] refer to figure 1 and Figure 7 On the basis of the second embodiment, in this embodiment, a flattening mechanism 5 is provided on the chain conveyor 3 on the side of the discharging mechanism 4 away from the feeding port 306 . After the glutinous rice grains are combed by the discharge mechanism, the thickness of the glutinous glutinous rice grains in the middle and both sides of the chain plate tends to be consistent, but the surface of the glutinous rice grains is still uneven. Therefore, the surface of the glutinous rice grains is flattened by the flattening mechanism, so that the glutinous rice glutinous rice grains on the chain plate are more tidy, the thickness is completely consistent, and the drying efficiency is improved.

[0085] refer to Figure 10 , the flattening mechanism 5 of this embodiment includes a flattening plate 501 arranged in the width direction of the chain conveyor 3, and has a simple structure and convenient installation and maintenance.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com