Capture method of heavy metals and ultrafine particles in the process of solid waste incineration

A technology for solid waste and ultra-fine particles, applied in combustion methods, separation methods, dispersed particle filtration, etc., can solve problems such as low efficiency, reduce costs, promote adhesion, and implement simple and easy effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

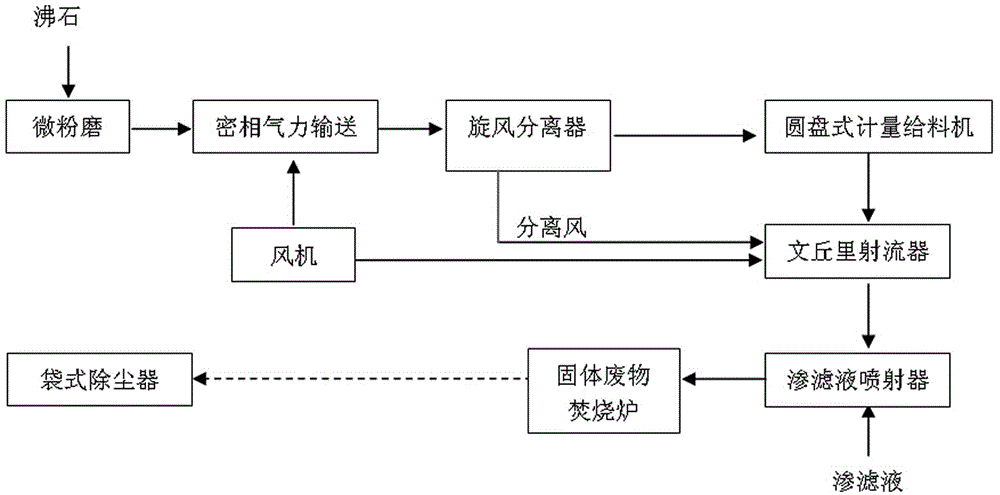

[0038] First, the zeolite is fed into the micro-powder mill through the screw feeder and crushed into zeolite powder between 300-400 mesh; the crushed zeolite powder is transported to the cyclone separator through the dense phase pneumatic conveying device, and is separated by the cyclone separator and then passed through the disc The amount of zeolite powder entering the Venturi ejector accounts for 3‰ of the total mass of municipal solid waste in the circulating fluidized bed incinerator; the mixed wind of the mixed zeolite powder is from the Venturi The inner jet enters the percolate ejector and mixes with the percolate into the hearth of the circulating fluidized bed incinerator. The temperature of the ejection position is 900℃±5℃; when the zeolite powder that captures heavy metals and ultrafine particles is smoked The gas leaves the circulating fluidized bed incinerator, and finally enters the bag filter, where it is efficiently captured by the bag filter and discharged to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com