Nitrogen oxide-containing waste gas treatment equipment

A kind of waste gas treatment equipment, nitrogen oxide technology, applied in the direction of gas treatment, air quality improvement, chemical instruments and methods, etc., can solve the problems of reducing waste gas treatment efficiency, difference in service life of adsorbents, ozone layer breaking, etc., to improve waste gas Processing efficiency, reducing the difficulty of maintenance and cleaning, and ensuring a clean and orderly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

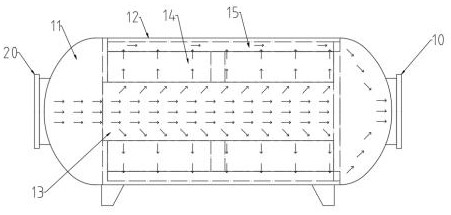

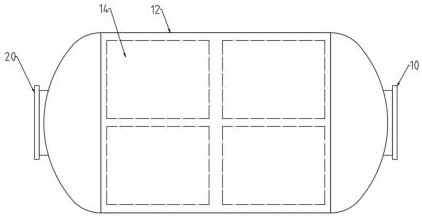

Method used

Image

Examples

Embodiment approach

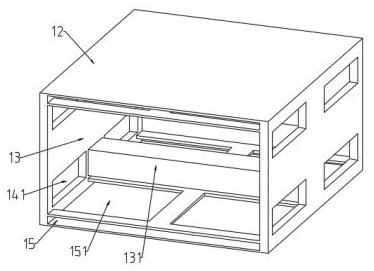

[0034] Another embodiment, the two sides of the closed film 152 are mounted on the electric slide rail, when opening the adsorption bed 14, the electric slide rail first drives the closed film 152 to seal the through hole 151, so that in the process of pulling out the adsorption bed 14, it can completely avoid exhaust gas overflow.

[0035]The adsorption bed 14 is provided with a baffle 143 on one side near the diffusion channel 13, the baffle 143 and the adsorption bed 14 is connected by a telescopic component, the telescopic component is an electric cylinder, a pneumatic cylinder, a hydraulic cylinder, etc., in the present embodiment, the telescopic component is a gear rack mechanism, such as Figure 10 , the telescopic assembly comprises a connecting rod 140, the connecting rod 140 is connected to the baffle 143 at one end, the other end extends to the adsorption bed 14, the connecting rod 140 has a tooth surface, the adsorption bed 14 is installed with the connecting rod 140 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com